High-strength honeycomb strips box

A honeycomb sheet, high-strength technology, used in the field of tobacco storage equipment, can solve the problems of inability to meet the requirements of the bearing capacity of the smoke box, anisotropy of the bending strength of the honeycomb core, and damage to the strength, and achieve excellent axial load bearing, Low production cost and the effect of improving compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

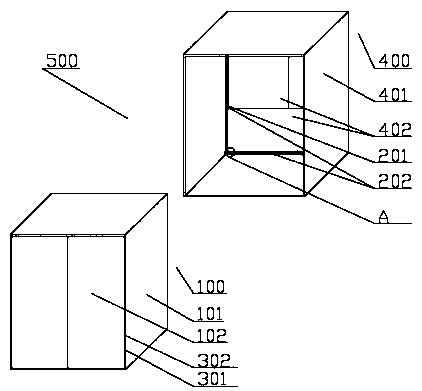

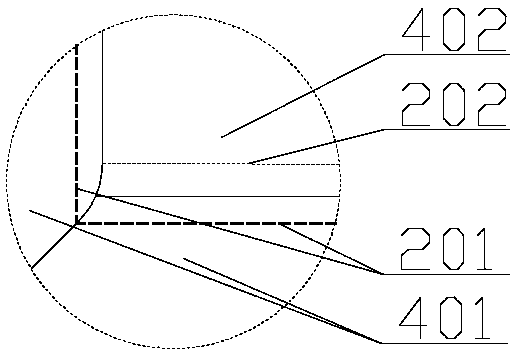

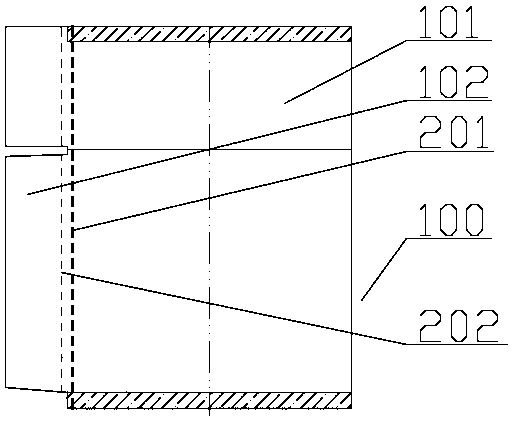

[0040] refer to Figure 1~4 , a high-strength honeycomb sheet smoke box 500 of the present embodiment, including an inner box 100 and an outer box 400, the inner box 100 and the outer box 400 are square structure boxes with openings on one side, and 100 sets of inner boxes It is arranged inside the outer box 400, and the openings of the inner and outer boxes 400 are arranged facing each other; the inner box 100 is composed of two pieces of cardboard spliced together, and each piece of cardboard is composed of an inner side panel 101 and an inner swing cover 102 connected to each other, and the inner side panel 101 Formed integrally with the inner swing cover 102; the outer box 400 is composed of two pieces of cardboard spliced together, and each piece of cardboard is composed of an outer side plate 401 and an outer swing cover 402 connected to each other, and the outer side plate 401 and the outer swing cover 402 are integrally formed; the inner side The folding structure ...

Embodiment 2

[0053] Compared with embodiment 1, a kind of high-strength honeycomb sheet smoke box of the present embodiment has the following differences:

[0054] The number of the inner indentations is 3, including the first inner indentation, the second inner indentation and the third inner indentation, the depth of the first inner indentation is greater than that of the second inner indentation and the third inner indentation depth; and the distance between two adjacent inner indentations is 8-15mm; the number of outer indentations is 2, including the first outer indentation and the second outer indentation; the first outer indentation and the second outer indentation The outer indentations are respectively located between the first inner indentation and the second inner indentation, the first inner indentation and the third inner indentation; the depth of the first outer indentation is greater than that of the second outer indentation. The number of the inner indentations is 3, includ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com