Board feeding mechanism for woodworking machinery

A technology of feeding mechanism and woodworking machinery, which is applied to wood processing appliances, processing machines for manufacturing flat surfaces, manufacturing tools, etc. It can solve the problems affecting the quality of wood processing, feeding deviation, inclination, etc., and achieve the effect of ensuring the quality of subsequent processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

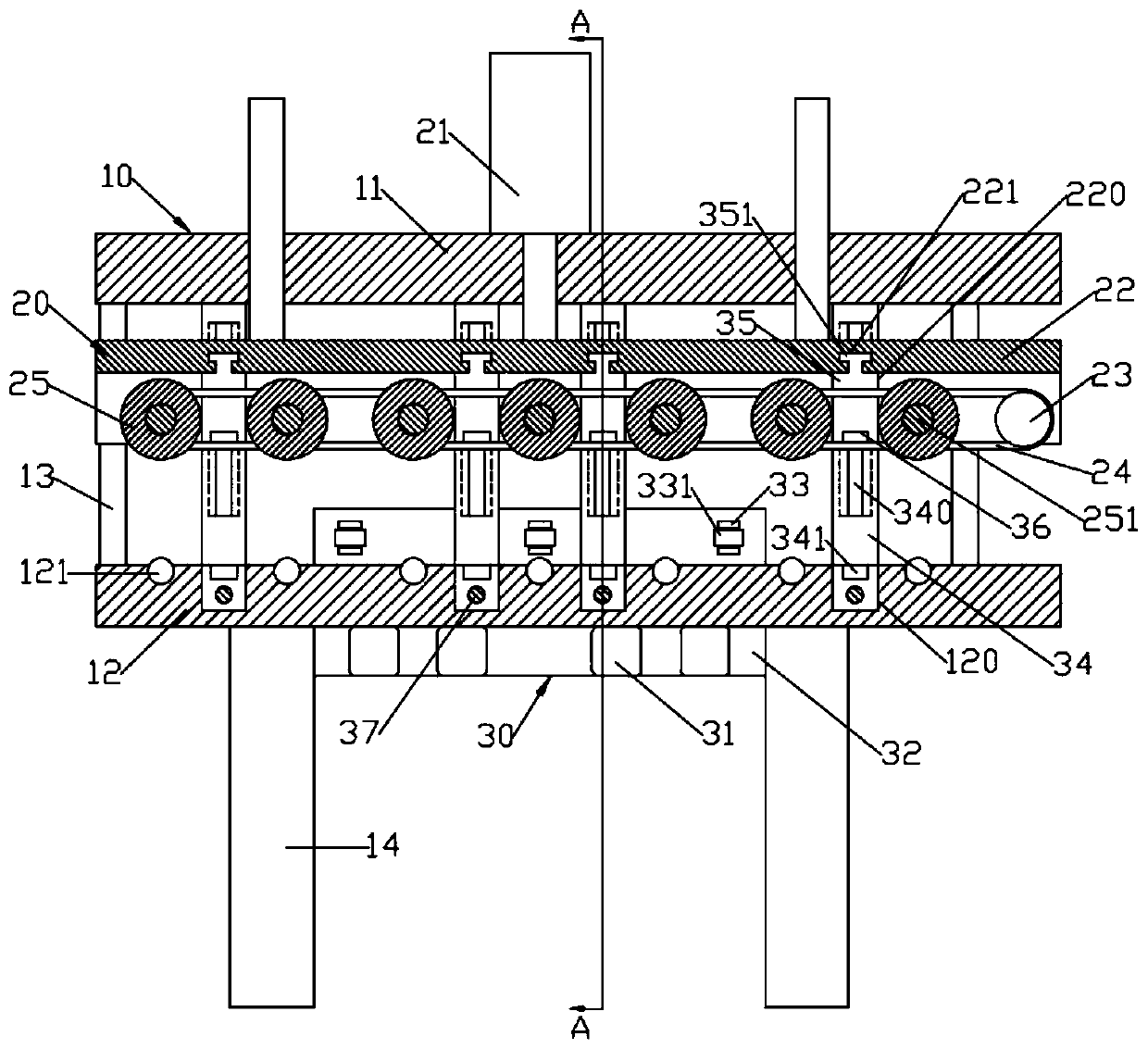

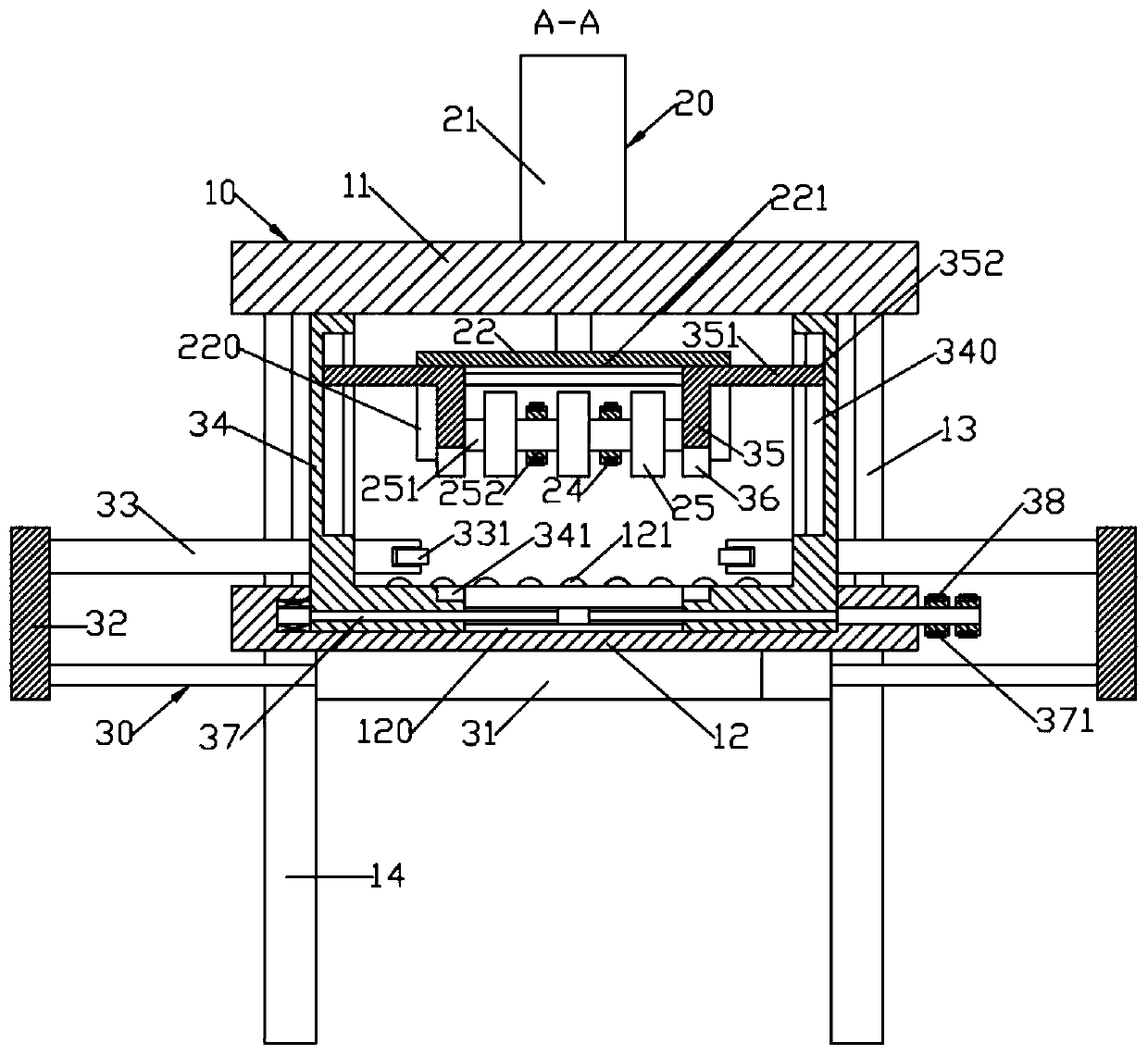

[0015] Such as figure 1 and figure 2 Shown, a kind of plank feeding mechanism for woodworking machinery, comprises support 10 and conveying device 20; Support 10 comprises upper support plate 11 and lower support plate 12 distributed up and down; Support feet 14; the upper support plate 11 and the lower support plate 12 are connected into one body by several evenly distributed vertical connecting rods 13; The "凵"-shaped lifting support base 22 arranged below; a pair of vertical parts of the lifting support base 22 are synchronously rotated in the same direction and are provided with several upper rollers 25; a pair of vertical parts of the lifting support base 22 are formed with several The avoidance holes 220 arranged in the front and back of the left and right distribution; also include a deviation correction device 30; the deviation correction device 30 includes several pairs of illuminant support plates 35, several pairs of photoelectric sensor support plates 34 and a pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com