Board feeding mechanism with oscillating rod correction function

A feeding mechanism and wood board technology, which is applied in the direction of manufacturing flat surface processing machines, wood processing appliances, adjustment equipment, etc., can solve the problems that affect the quality of wood processing, feeding deviation, inclination, etc., and achieve the effect of ensuring the quality of subsequent processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

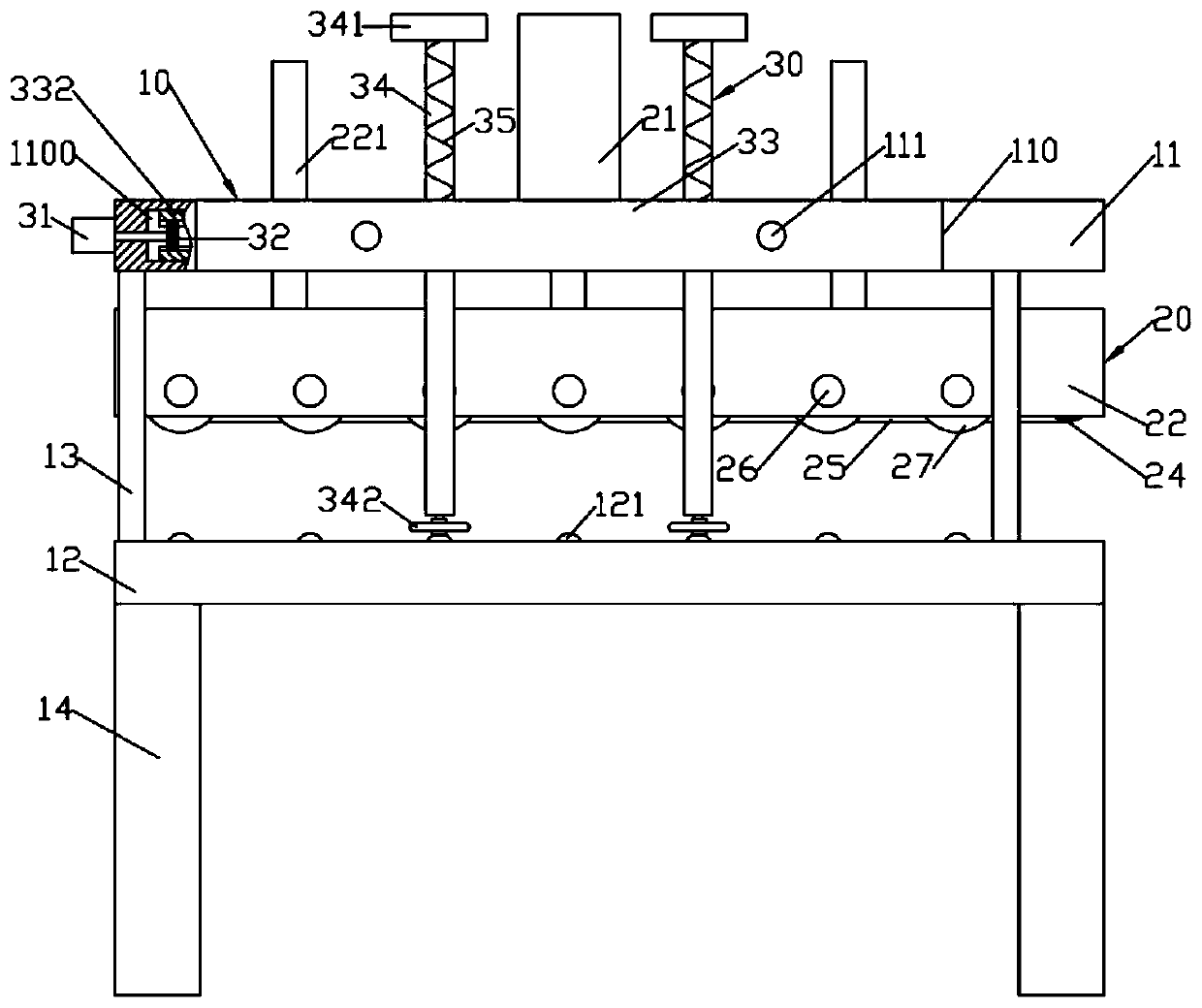

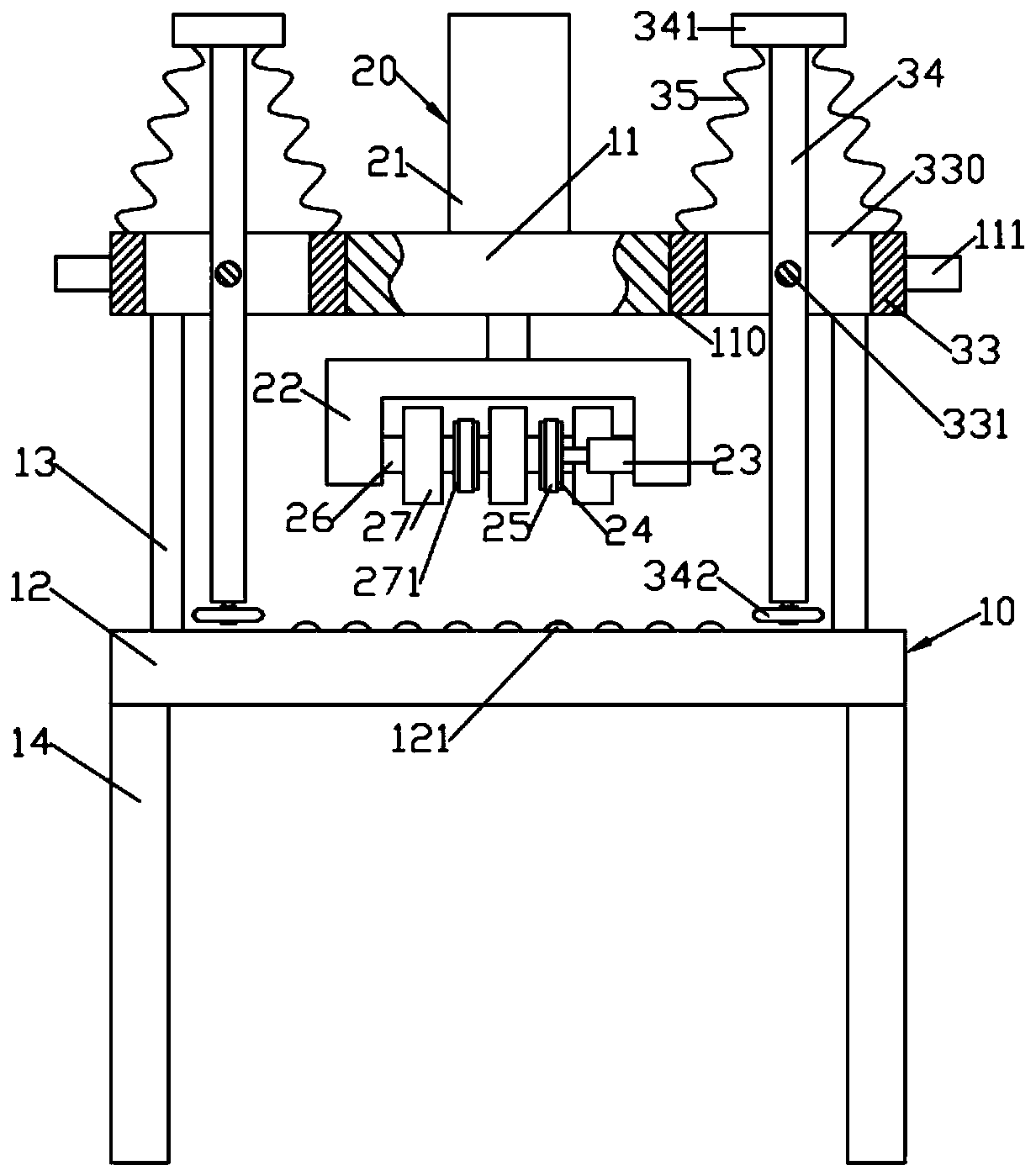

[0014] like figure 1 and figure 2 As shown, a plank feeding mechanism corrected by a swing bar includes a bracket 10 and a transmission device 20; the bracket 10 includes an upper support plate 11 and a lower support plate 12 distributed up and down; The supporting feet 14; the upper supporting plate 11 and the lower supporting plate 12 are connected into one body by several evenly distributed vertical connecting rods 13; The "凵"-shaped lifting support base 22 set downward; a pair of vertical parts of the lifting support base 22 are synchronously rotated in the same direction with a number of upper rollers 27; it also includes a pendulum correction device 30; the upper support plate 11 The front and rear end faces are formed with front and rear moving grooves 110 respectively; the front and rear moving grooves 110 run through and are set up and down; the pendulum correcting device 30 includes a pair of cuboid-shaped adjusting support seats 33 and several pendulum bars 34; I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com