Fully-automatic door frame turret punch

A fully automatic, turret technology, used in metal processing equipment, feeding devices, stripping devices, etc., can solve problems such as poor machining accuracy, low work efficiency, and product availability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

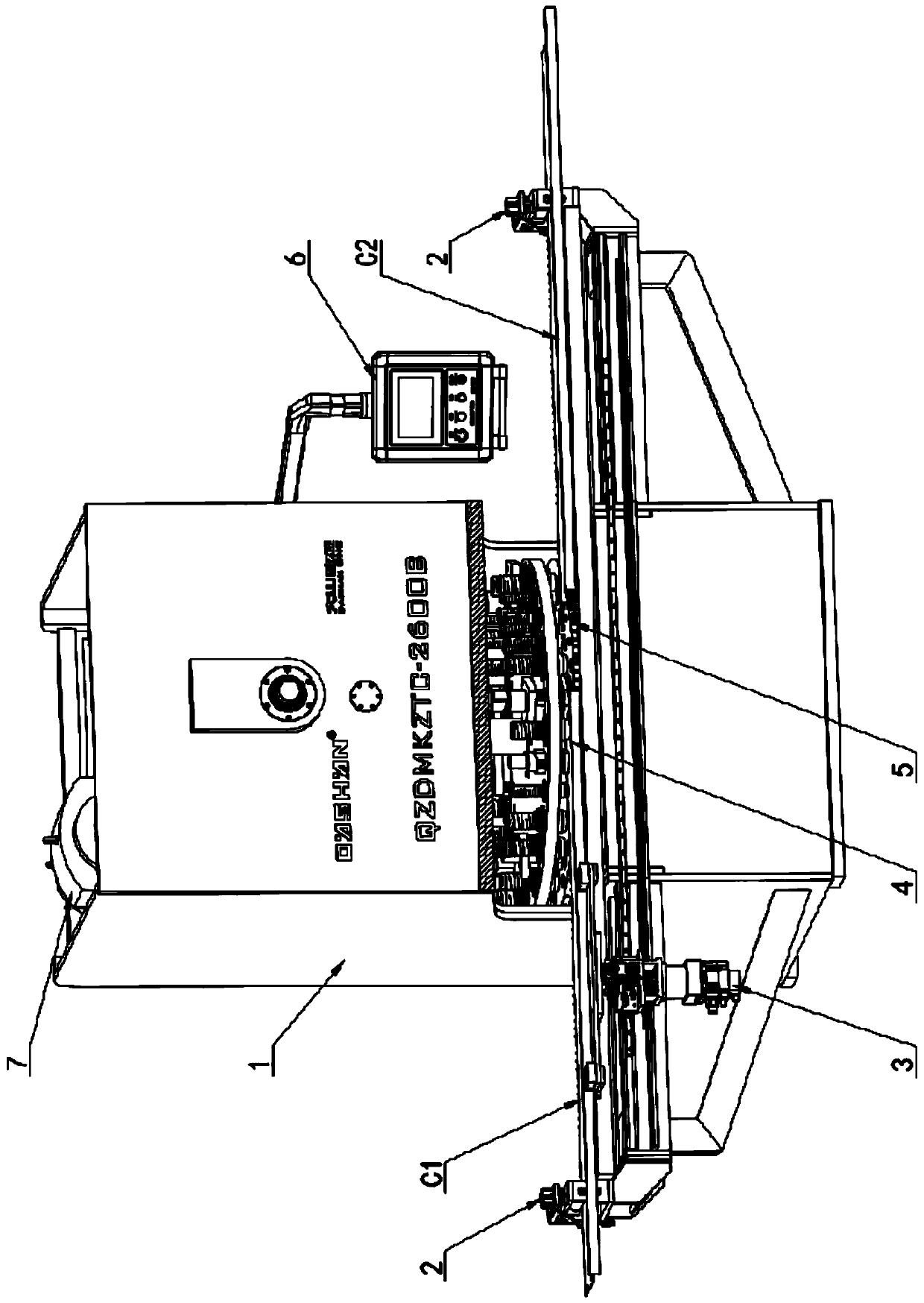

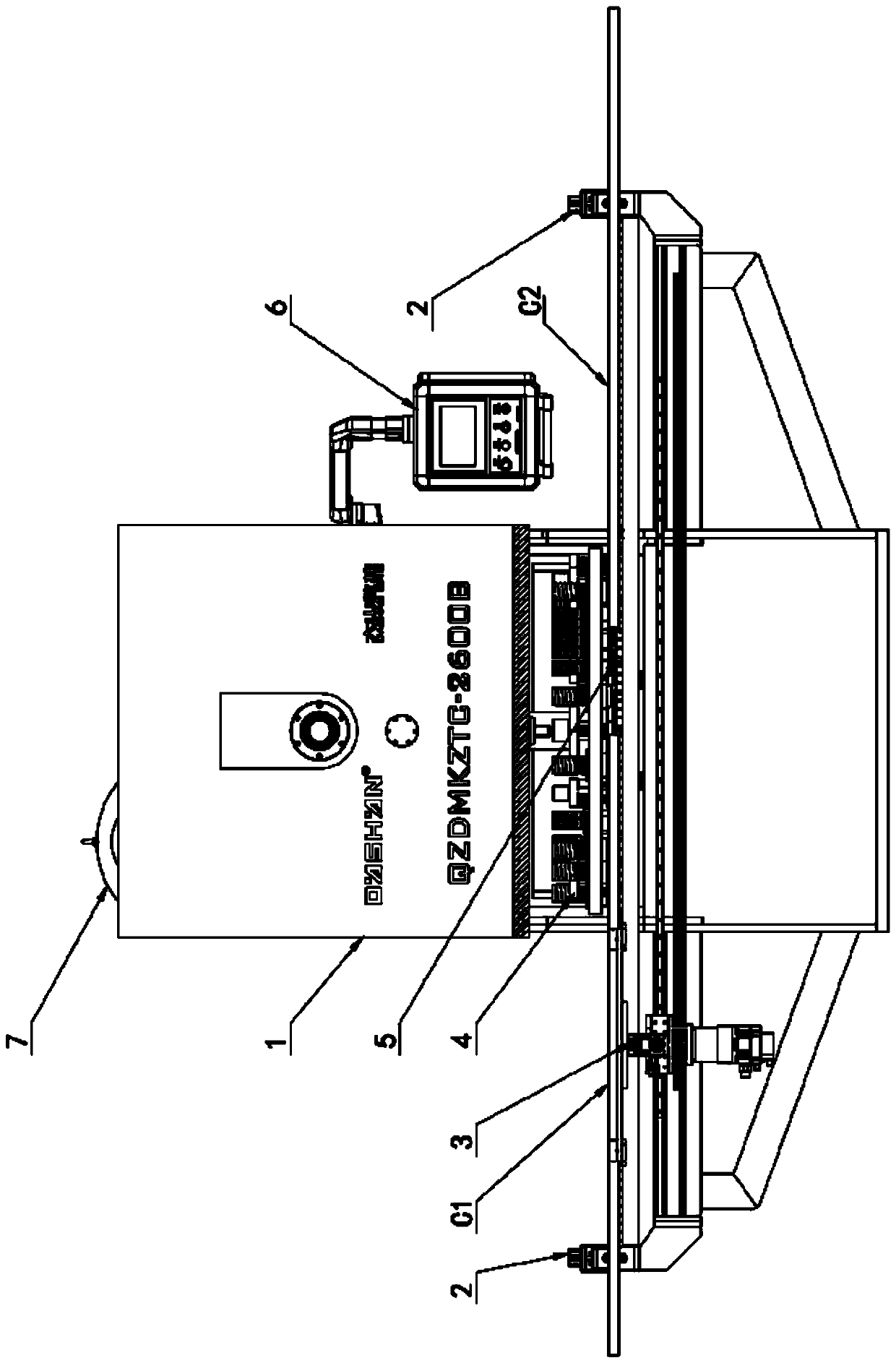

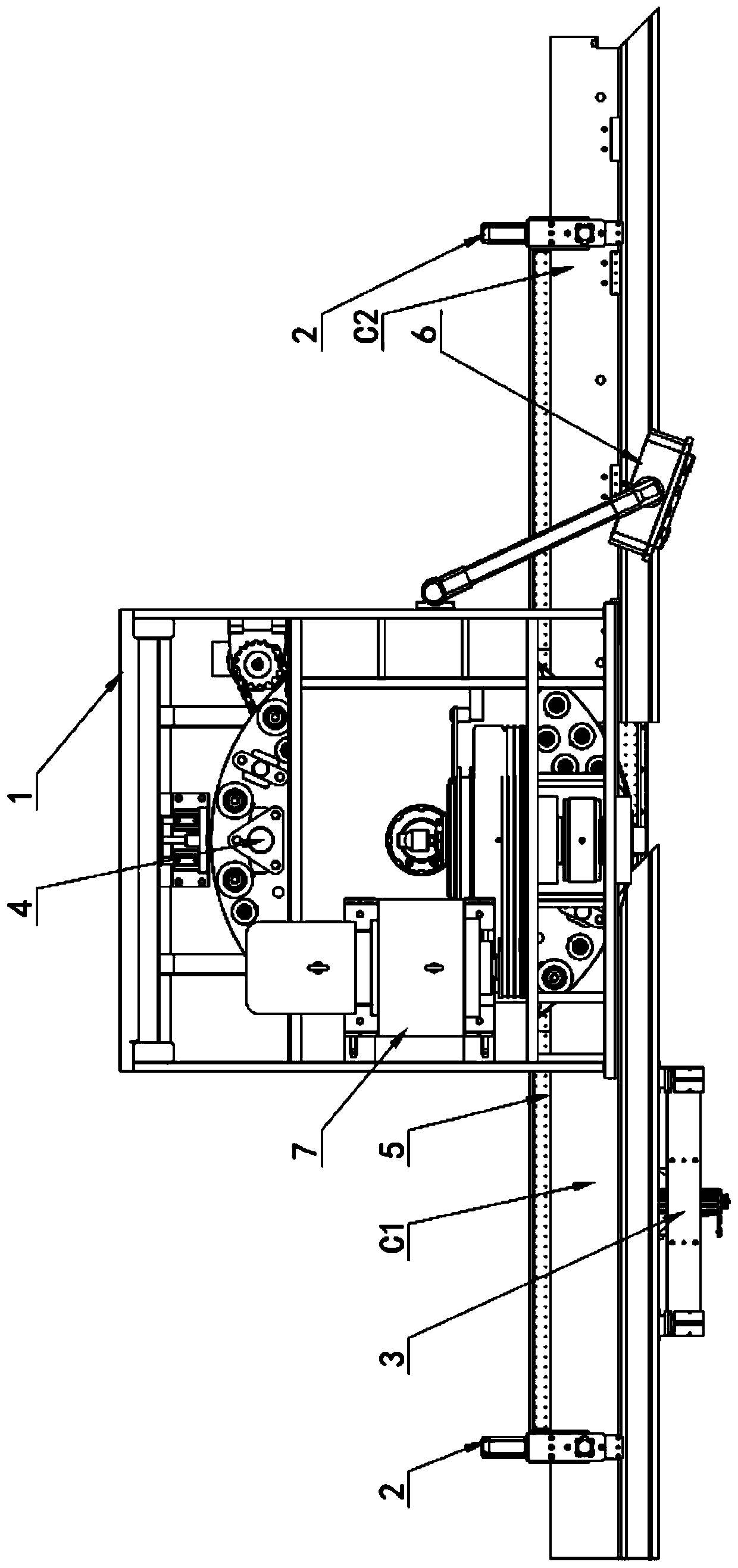

[0026] Figure 1 to Figure 10 As shown, the invention creates a specific embodiment of a fully automatic door frame turret punch, including a main frame 1, a conveying device 2 fixedly installed on the main frame 1, a feeding device 3, a rotating device 4, a brush plate 5, and a control unit 6. Stamping device 7, gas source station, and waste material collection box. The feeding device 3 includes a feeding line rail pair 313 fixedly installed on the main frame 1, a feeding rack 314, and a belt that moves along the left and right direction of the feeding line rail pair 313. Feeding reducer base 304; feed motor 301, feed reducer 302, feed main gear 303, linear module 305 fixedly installed on the feed reducer base 304; short beam 306, fixedly installed on the linear module 305 slide table, The long beam 307 and the tooling bottom plate 308 suitable for clamping the pre-stamping sheet (after forming) C1, the feeding clamping cylinder 309, the pressure plate 310, the clamping press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com