Vibration exciter

A vibration exciter and vibration excitation technology, which is applied in the direction of fluid using vibration, can solve the problems of achieving optimal excitation force parameters, poor adjustment accuracy, and difficulty in eccentricity, achieve accurate control parameters, and avoid excessive current damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

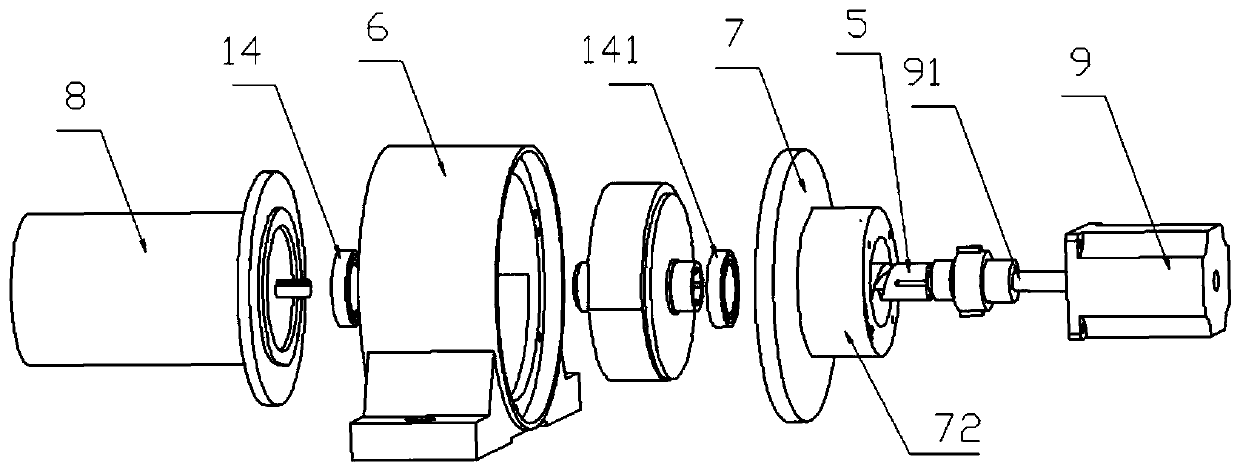

[0039] Such as figure 1 as shown, figure 2 and Figure 5 As shown, an exciter includes an eccentric vibrator, an excitation box 6 for accommodating the eccentric vibrator, an excitation motor 8 for driving the eccentric vibrator to rotate, and a servo linear motion system 9 for adjusting the eccentricity of the eccentric vibrator .

[0040] The eccentric vibrator includes an outer eccentric body 1, an inner eccentric body 2 and a connecting shaft 5, the outer eccentric body 1 has an inner peripheral surface, the inner eccentric body 2 has an outer peripheral surface, and the inner circumference of the outer eccentric body 1 A first bearing 41 and a second bearing 42 are arranged between the surface and the outer circumferential surface of the inner eccentric body 2; the centers of gravity of the inner eccentric body 2 and the outer eccentric body 1 deviate from the first bearing 41 and the second bearing 42 to form the center of gyration.

[0041] The inner peripheral sur...

Embodiment 2

[0057] Same as Embodiment 1, the difference lies in that the fixed connection method between the servo linear motion system 9 and the vibration excitation box cover 7 is different. The connection mode provided in this embodiment is: the servo linear motion system 9 is provided with a servo linear motion system seat 13, and the servo linear motion system seat 13 is fixedly connected with the vibration excitation box cover 7; the vibration excitation box cover The through hole 71 is located at the center of the connection between the vibration excitation box cover 7 and the servo linear motion system seat 13 . The servo linear motion system seat 13 is provided with a servo linear motion system seat through hole 131, and the servo linear motion system actuator 91 of the servo linear motion system 9 passes through the servo linear motion system seat through hole 131 and contacts with the servo linear motion system seat. One end of the connecting shaft 5 is connected through a fift...

Embodiment 3

[0059] Same as Embodiment 1, except that the inner wall of the second shaft hole 21 is provided with a second spiral groove; the inner wall of the third shaft hole 31 is provided with a second linear groove; the connecting shaft 5 is arranged from left to right A third boss cooperating with the second helical groove and a fourth boss cooperating with the second linear groove are sequentially arranged.

[0060] There are two third bosses, which are arranged on the trajectory line matched with the second spiral groove; there are two fourth bosses, which are arranged on the trajectory line matched with the second linear groove superior.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com