A kind of metal-organic framework composite material grafted with ionic liquid and its preparation method and application

A metal-organic framework, ionic liquid technology, applied in organic compound/hydride/coordination complex catalysts, organic chemistry, chemical instruments and methods, etc., can solve the problems of non-reusability, difficult separation, etc. , the raw materials are easy to obtain, the catalytic effect is remarkable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

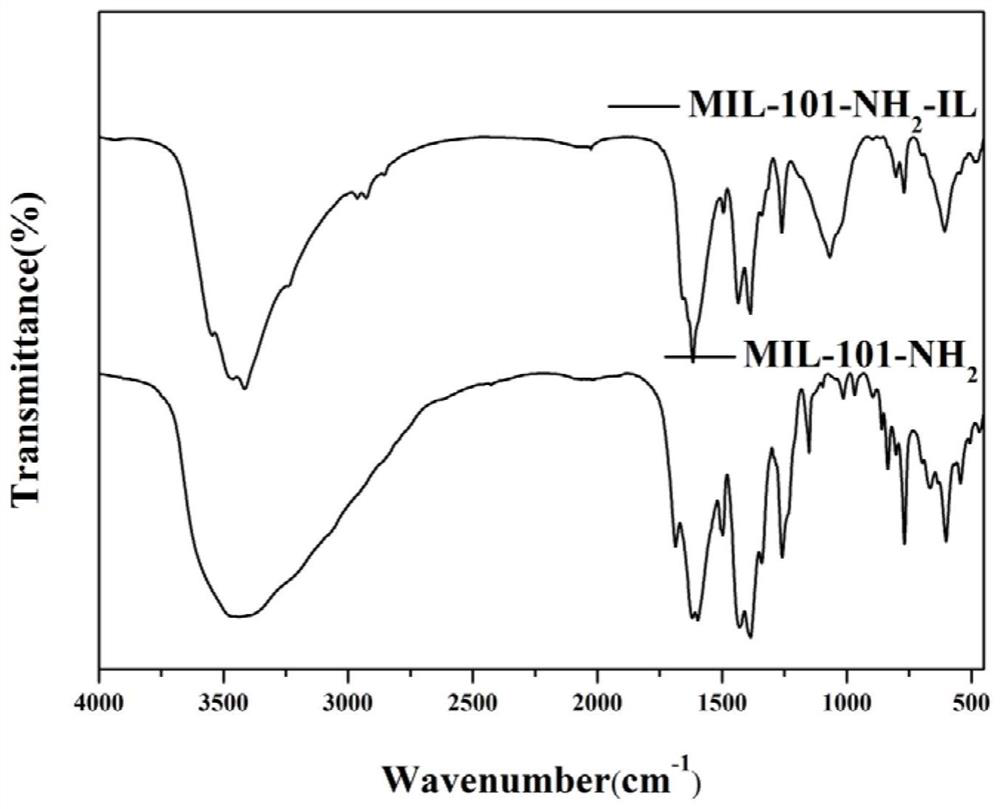

[0022] Example 1 Metal-organic framework composite MIL-101-NH grafted with ionic liquid 2 -IL

[0023] (1) The preparation method is as follows

[0024] 1. Metal organic framework MIL-101-NH 2 preparation

[0025] 2 mmol of Cr(NO 3 ) 3 ·9H 2 O, 2 mmol of 2-aminoterephthalic acid, 5 mmol of NaOH and 15 mL of deionized water were added to the autoclave and kept at 150°C for 12 hours to obtain a green product. The green product was washed with deionized water, filtered, and dried at 120 °C. The obtained product was heated at 80 °C with methanol for 12 h, filtered and dried to obtain MIL-101-NH 2 , the yield is 89%.

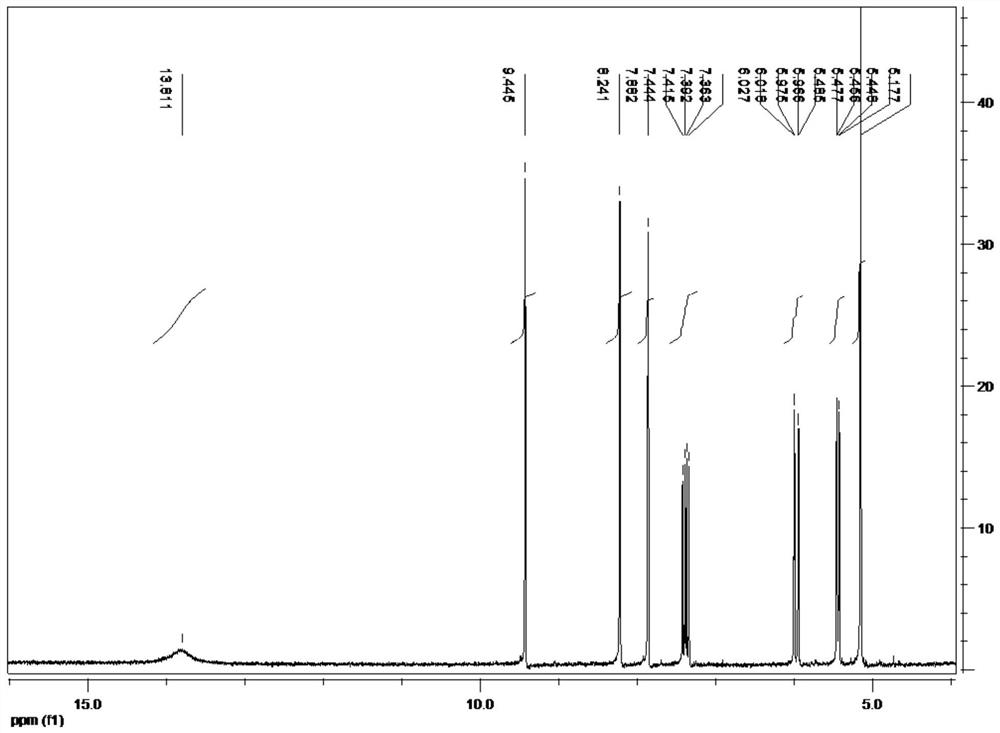

[0026] 2. Synthesis of ionic liquid 1-vinyl-3-carboxymethylimidazolium bromide (IL)

[0027] Acetone pretreatment: The acetone was placed in a round-bottomed flask and sealed, and nitrogen was continuously introduced for acetone degassing.

[0028] 53 mmol of 1-vinylimidazole and 67 mmol of bromoacetic acid were added to 20 mL of acetone, and the mixture was...

Embodiment 2

[0039] Metal-organic framework composites MIL-101-NH grafted with ionic liquids 2 -IL catalyzes the cycloaddition reaction of carbon dioxide and propylene oxide, and the reaction formula is as follows:

[0040]

[0041] (1) Effects of different catalysts on the cycloaddition reaction of carbon dioxide and propylene oxide

[0042] The method is as follows: take 10 mmol of propylene oxide, 50 mg of catalyst MIL-101-NH 2 -IL was placed in a stainless steel autoclave at 80° C. and 1MPa, and the reaction was stirred for 12 hours, and the product propylene carbonate was obtained by gas phase detection. The calculated yield was 97%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com