Composite filter core assembly and water purification system

A technology of composite filter element and filter element group, which is applied in the direction of water/sewage treatment, chemical instruments and methods, water/sewage treatment equipment, etc., can solve problems such as easy scaling and blockage of composite filter elements, so as to prevent blockage, slow down flow speed, The effect of reducing the possibility of fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

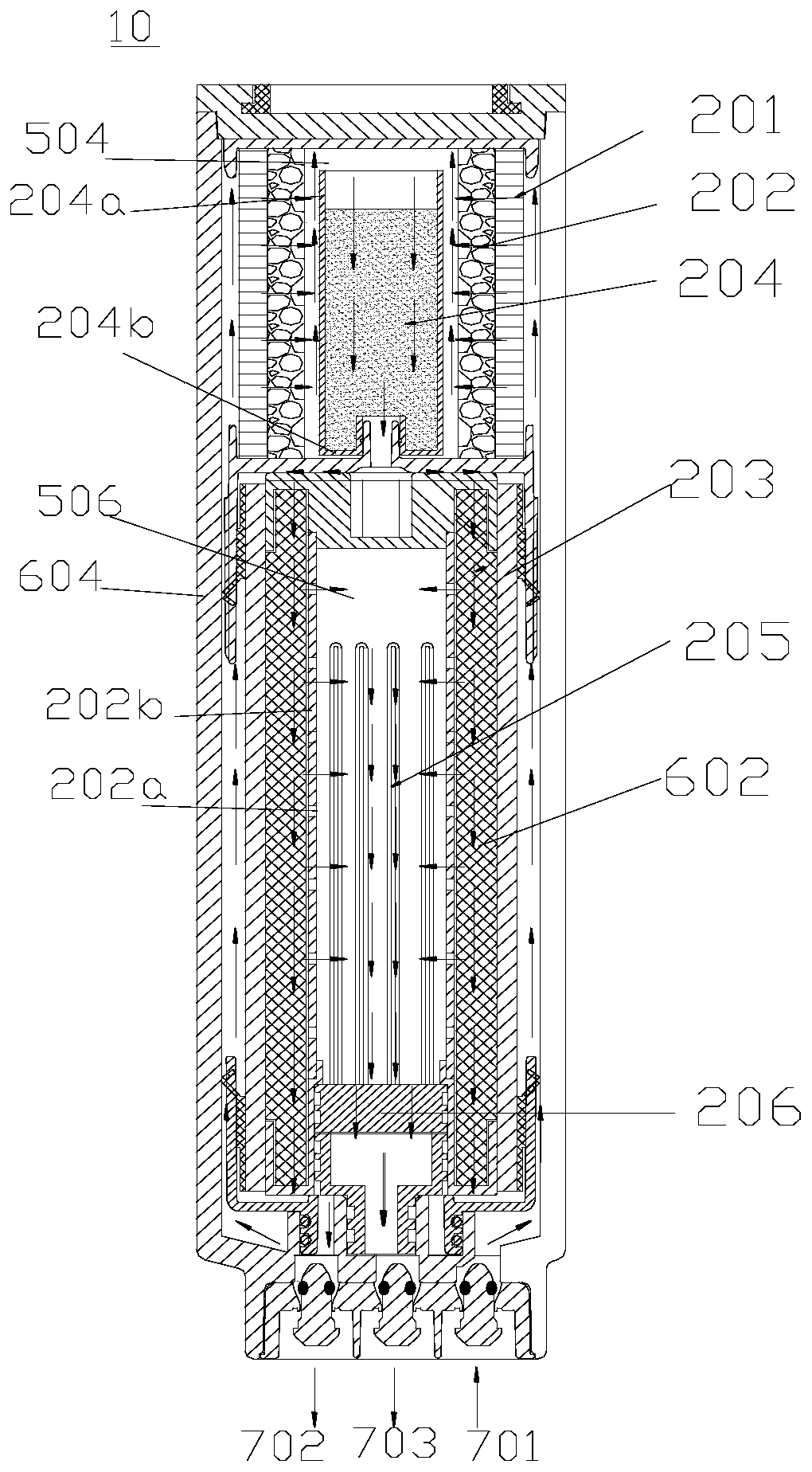

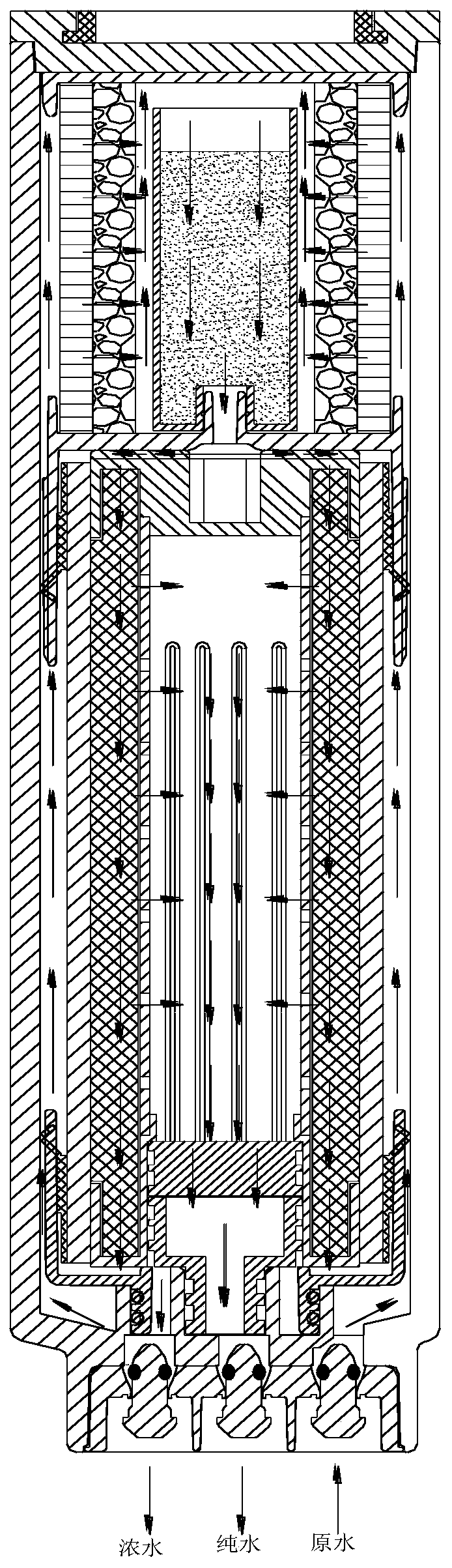

[0039] Such as Figure 1-2 As shown, the present invention provides a composite filter element assembly, characterized in that: comprising:

[0040] The bottle body 604 and the multi-stage filter element arranged inside the bottle body include a pretreatment filter element, a fine filter element 203, and a post-treatment filter element group; It is made of a filter material that allows fluid to pass through; the fluid is filtered through the pretreatment filter element, the fine filter element, and the post-treatment filter element group in sequence, and along the direction of fluid flow, between the pretreatment filter element and the post-treatment filter element group A descaling filter element 204 is also arranged between the fine filter elements 203 .

[0041]The present invention sets the descaling filter element inside the sintered carbon rod by setting the multi-stage filter element inside the bottle body and the descaling filter element between the pretreatment filte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com