Noise reduction installation structure of transformer shell

An installation structure and technology for transformers, applied in the field of transformers, can solve problems such as lack of noise reduction function, achieve simple and fast connection operation, improve shock absorption effect, and avoid loosening effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

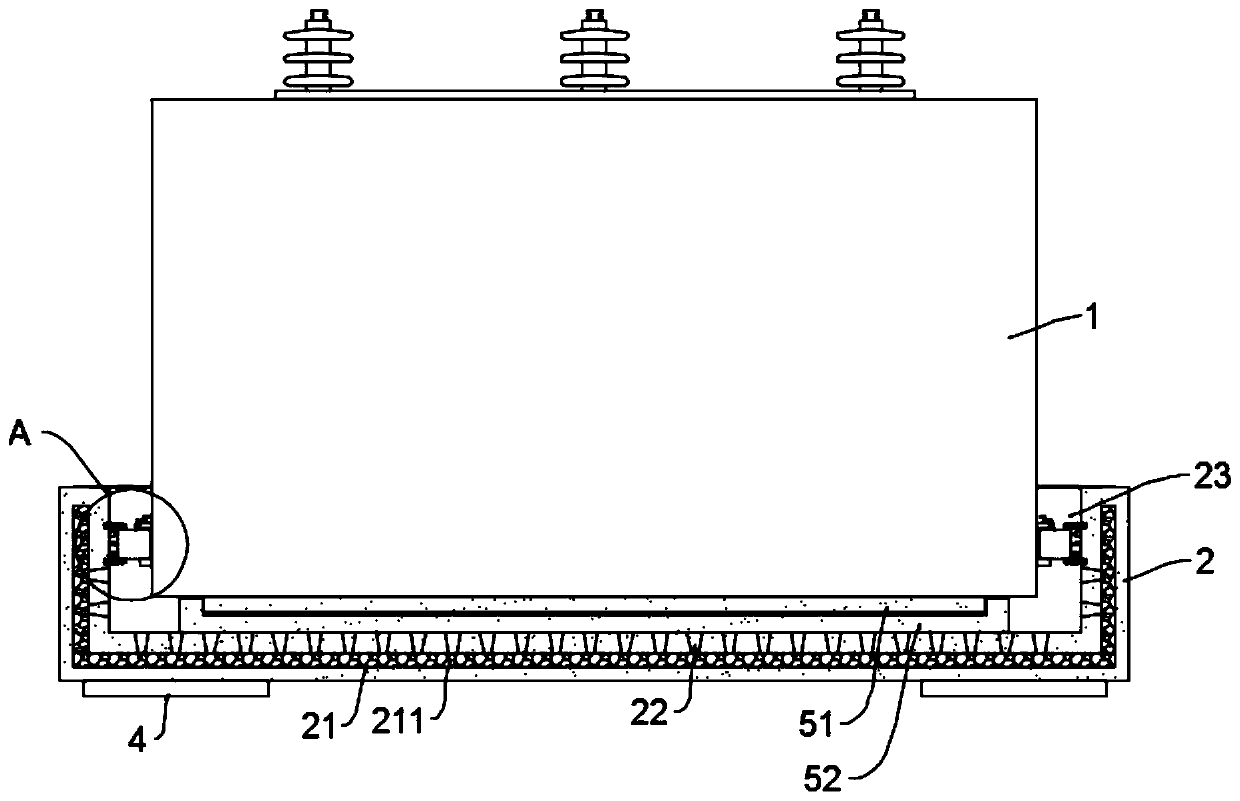

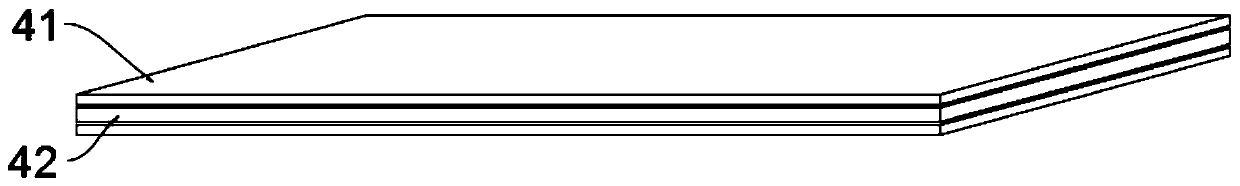

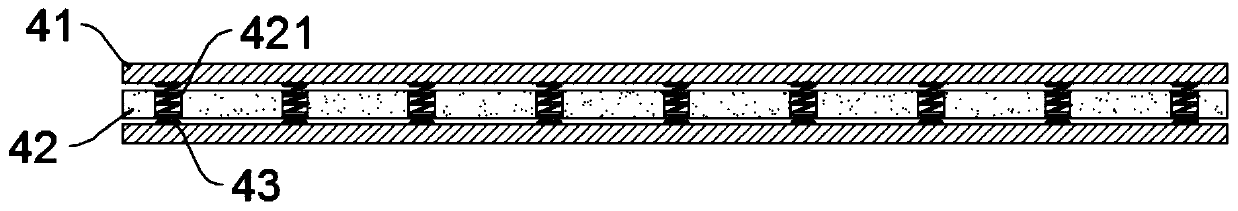

[0023] see Figure 1~3 , in an embodiment of the present invention, a noise reduction installation structure for a transformer housing includes a transformer housing 1 and a mounting base 2; the transformer housing 1 is connected to the mounting base 2 through a connection structure, and a cavity 21 is opened in the mounting base 2, The cavity 21 is filled with sound-absorbing cotton 211, and the shell wall of the mounting seat 2 is provided with a perforation 22 communicating with the cavity 21. The perforation 22 is trumpet-shaped and its big mouth is set towards the direction of the transformer shell 1, so that during operation The generated noise will enter into the cavity 21 through the perforation 22, and the noise will be weakened by the perforation 22 for the first time, and then the noise will be weakened by the sound-absorbing cotton 211 in the cavity 21 for the second time, thus effectively reducing the noise. noise effect.

[0024] Since part of the noise generate...

Embodiment 2

[0029] see figure 1 and 4 , the embodiment of the present invention describes the connection structure in detail on the basis of embodiment 1, specifically:

[0030] The connecting structure includes a rotating sleeve 31, a block 32 and a slot 34. The rotating sleeve 31 is rotatably connected to the outer wall of the mounting base 2, and the locking block 32 is inserted in the rotating sleeve 31 and connected to the rotating sleeve 31 through thread fit. , the side of the clamping block 32 close to the mounting base 2 is connected with the mounting base 2 through the telescopic rod 33, so that when the rotating sleeve 31 is rotated, the clamping block 32 will move linearly, and the clamping groove 34 is fixed on the outer wall of the transformer housing 1 , the notch of the card slot 34 is facing the card block 32, so that when installing, it is only necessary to position the transformer housing 1, and then complete the connection between the card block 32 and the card slot 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com