A kind of preparation method of zero power consumption pressure sensor

A pressure sensor, zero power consumption technology, applied in the direction of measuring fluid pressure, measuring fluid pressure through electromagnetic components, instruments, etc., can solve the problems of narrow detection range, low sensitivity, incompatibility, etc., to achieve improved measurement range, high sensitivity, The effect of large deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The terms "first", "second" and the like in the specification and claims of the present application and the above drawings are used to distinguish similar objects, and are not necessarily used to describe a specific sequence or sequence. It is to be understood that the data so used are interchangeable under appropriate circumstances such that the embodiments of the application described herein can be practiced in sequences other than those illustrated or described herein.

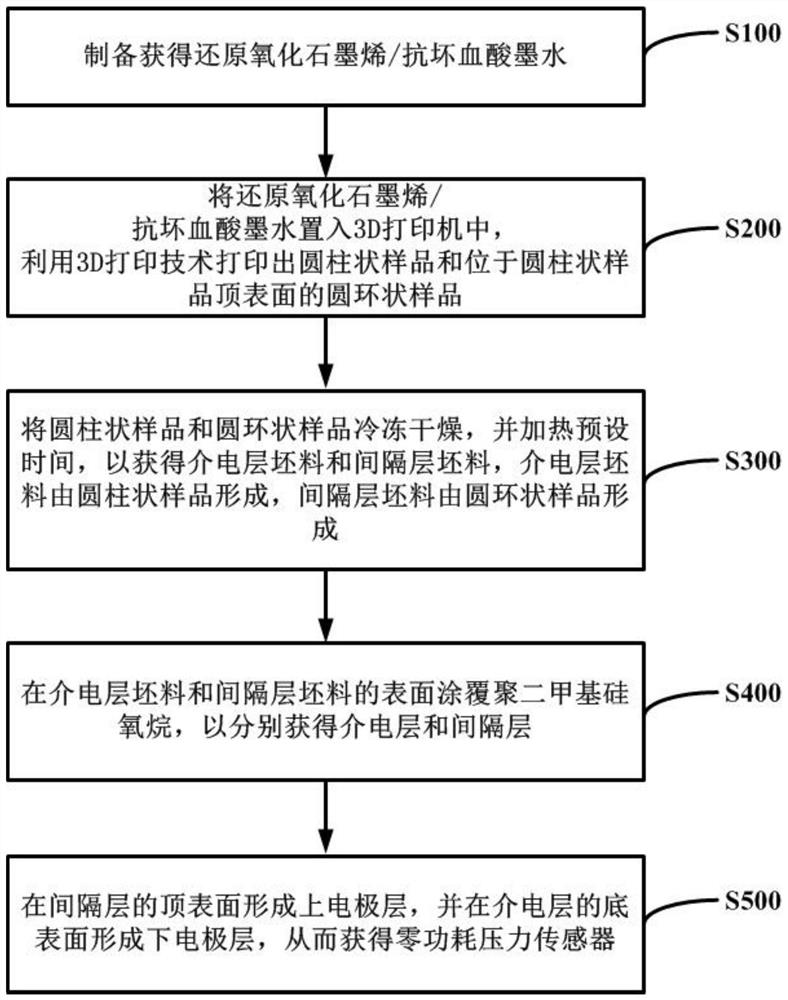

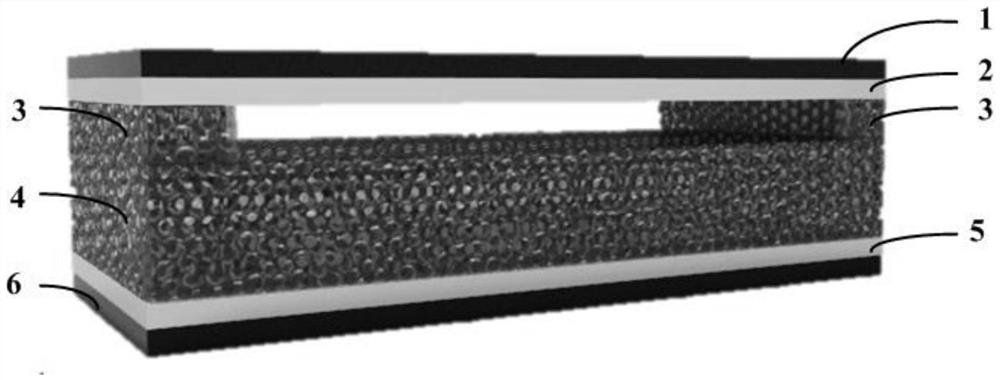

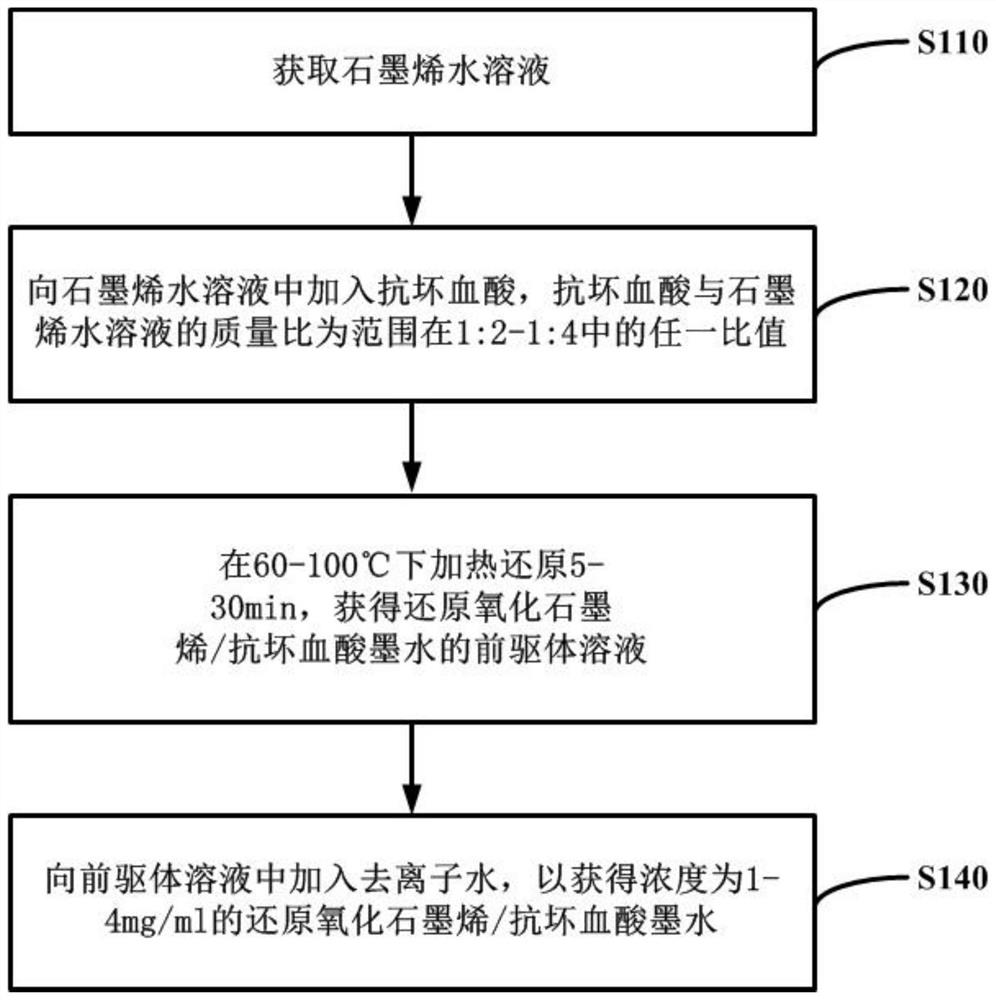

[0042] figure 1 A schematic flowchart of a method for manufacturing a zero-power consumption pressure sensor according to an embodiment of the present invention is shown. figure 2 A schematic cross-sectional view of a zero-power consumption pressure sensor according to an embodiment of the present invention is shown. Such as figure 1 Shown, the preparation method of this zero power consumption pressure sensor comprises:

[0043] Step S100, preparing reduced graphene oxide / ascorbic acid ink;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com