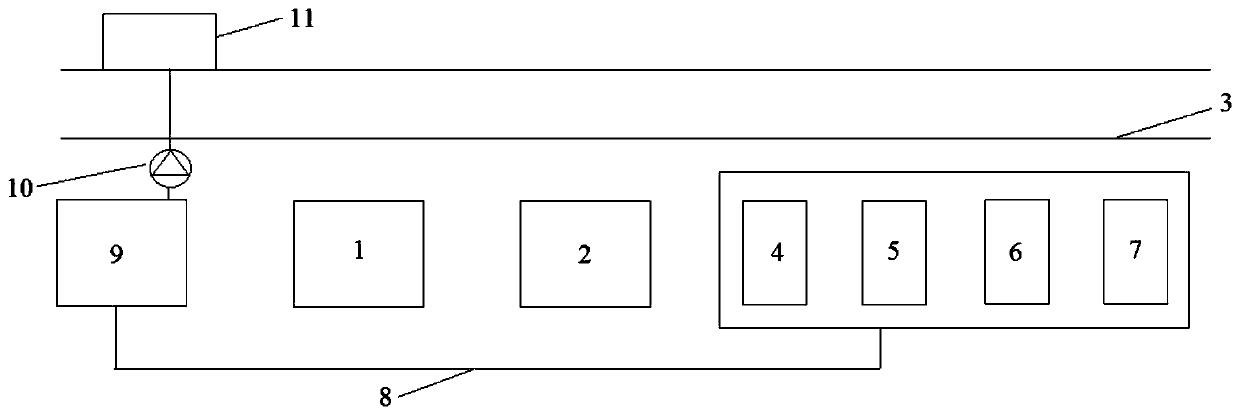

Sewage treatment process and device for outdoor flush toilets in alpine regions

A technology for high-cold regions and sewage treatment, applied in biological water/sewage treatment, water/sludge/sewage treatment, biological sludge treatment, etc. It has the effect of strong resistance to temperature disturbance, strong applicability and simple steps for problems such as organic matter decomposition ability and denitrification bacteria sensitivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0056] According to a preferred embodiment of the present invention, the volume ratio of the three compartments in the septic tank 1 is 2:1:3.

[0057] Among them, the ratio of the cell volume near the water inlet of the septic tank: the volume of the middle cell: the volume of the cell near the water outlet of the septic tank is 2:1:3.

[0058] Further, the retention time of the septic tank 1 for sludge and suspended solids is not less than 45 days.

[0059] In the present invention, the three-compartment septic tank can retain part of the suspended particles in the sedimented sewage, decompose and sterilize, and realize the separation of mud and water, so that the sewage from flushing toilets can be preliminarily purified.

[0060] In step 2, the sewage after preliminary purification is adjusted, and then deep purification is carried out.

[0061] In order to ensure the stability of the subsequent deep purification treatment, the toilet sewage after preliminary purification...

Embodiment 1

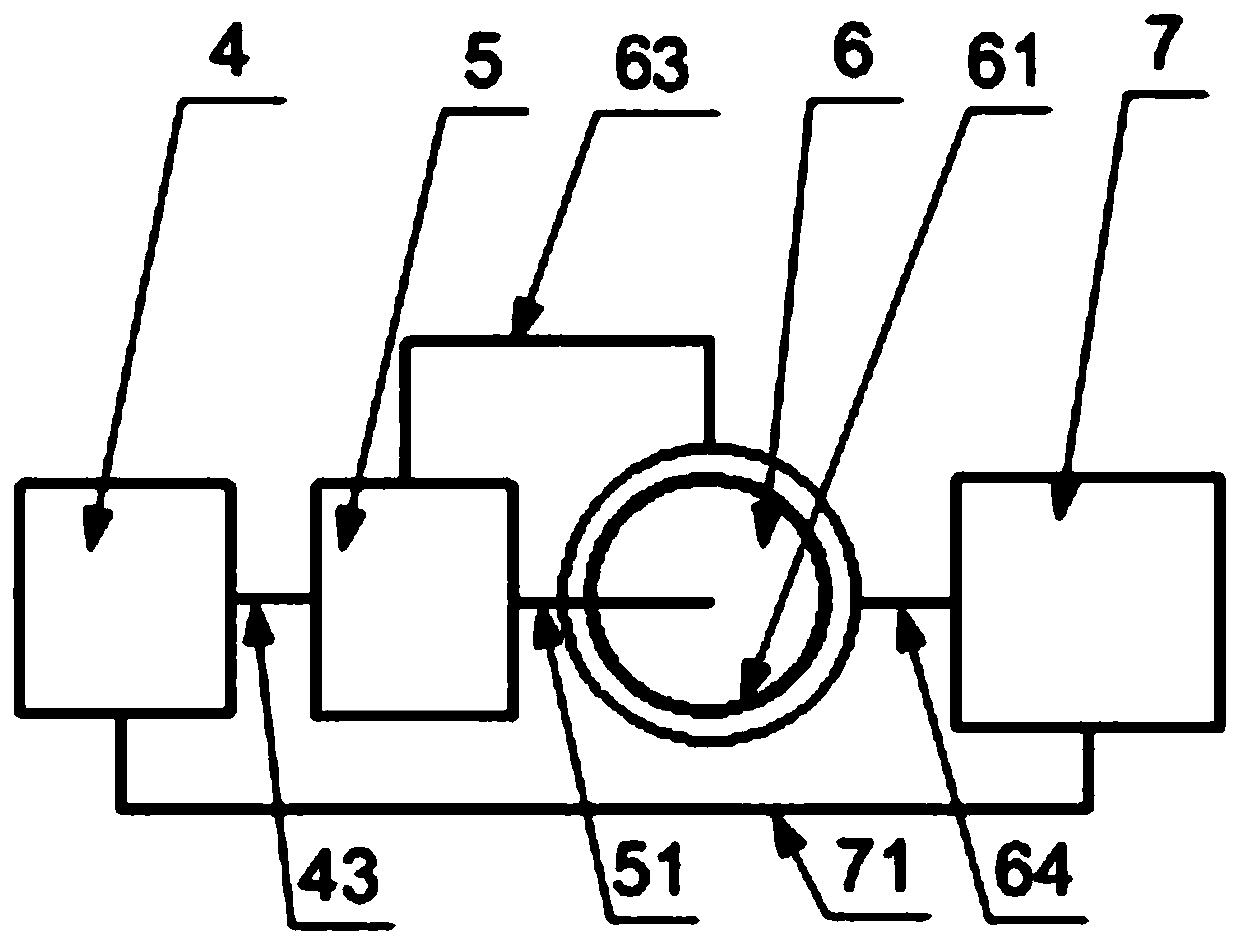

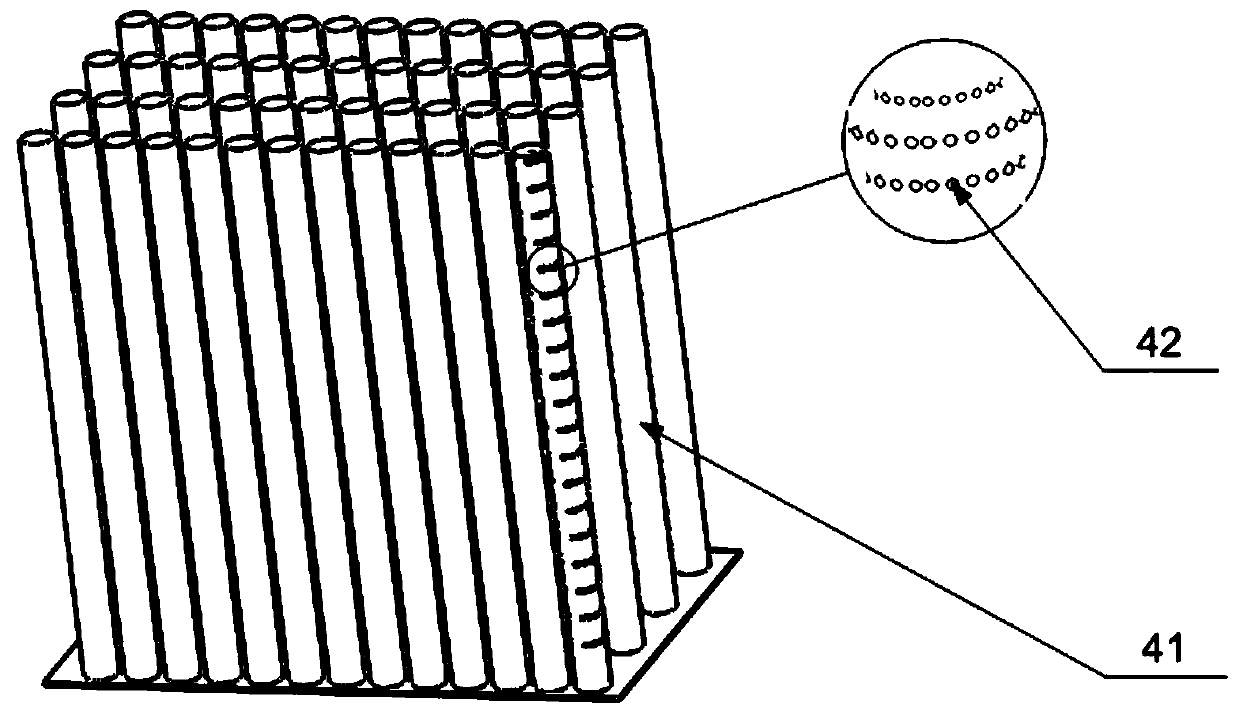

[0200] In the outdoor flushing toilet sewage treatment device adopted in this embodiment, the septic tank is a three-compartment septic tank, and the volume ratio of the three compartments is 2:1:3; the first filling mechanism and the second filling mechanism are both Active corrugated packing; the outer diameter of the aeration ring of the aerobic tank is 95% of the inner diameter of the aerobic tank;

[0201] The aeration layer has 4 layers, which are arranged in parallel up and down. Each aeration layer is concentrically arranged with 4 aeration rings from the inside to the outside; during the process of low-temperature sewage treatment, the air intake of the innermost aeration ring of the four-layer aeration layer The valves are all closed, so that the central area forms an anoxic zone;

[0202] The sludge used in the active filler film hanging in the anaerobic tank, anoxic tank and aerobic tank is prepared according to the following steps:

[0203] (i) Get the sludge in ...

Embodiment 2

[0210] In the outdoor flushing toilet sewage treatment device adopted in this embodiment, the septic tank is a three-compartment septic tank, and the volume ratio of the three compartments is 2:1:3; the first filling mechanism and the second filling mechanism are both Active corrugated packing; the outer diameter of the aeration ring of the aerobic tank is 90% of the inner diameter of the aerobic tank;

[0211] The aeration layer has 4 layers, which are arranged in parallel up and down. Each aeration layer is concentrically arranged with 4 aeration rings from the inside to the outside; during the process of low-temperature sewage treatment, the air intake of the innermost aeration ring of the four-layer aeration layer The valves are all closed, so that the central area forms an anoxic zone;

[0212] The sludge used in the active filler film hanging in the anaerobic tank, anoxic tank and aerobic tank is prepared according to the following steps:

[0213] (i) Get the sludge in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com