Side formwork arranging device for precast concrete component production line

A technology of prefabricated components and production lines, which is applied in the direction of manufacturing tools, conveyor objects, transportation and packaging, etc., and can solve problems such as large movement strokes and waste of time for side molds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

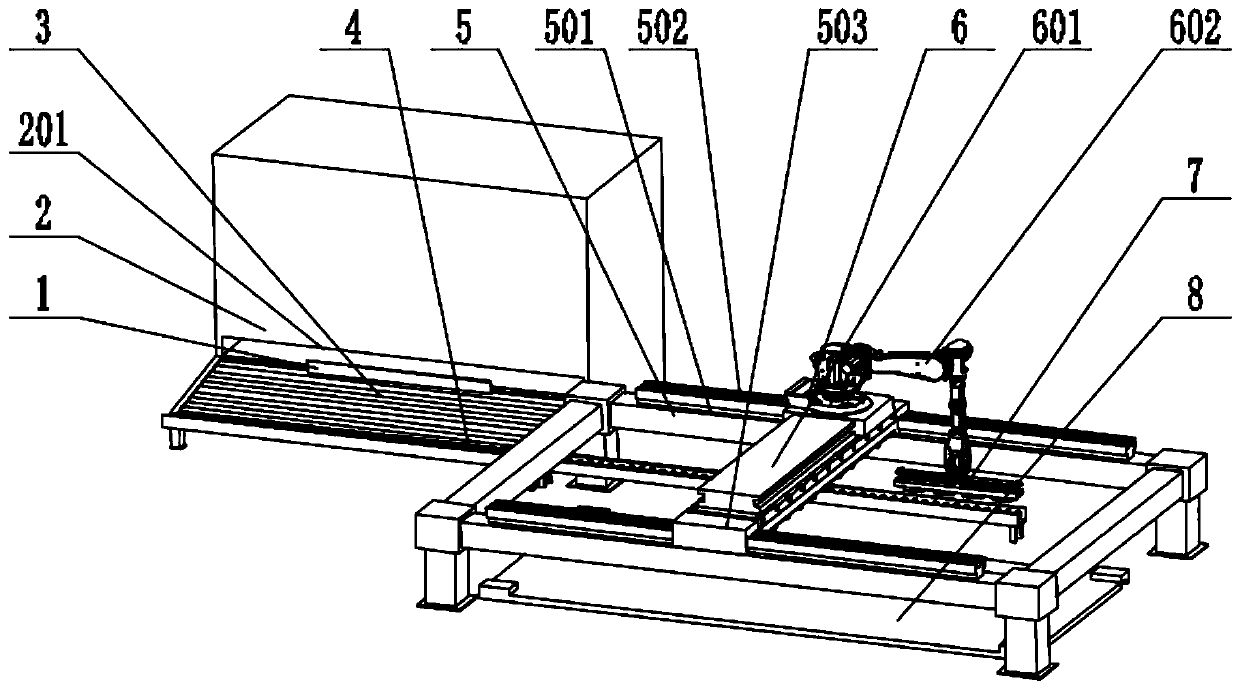

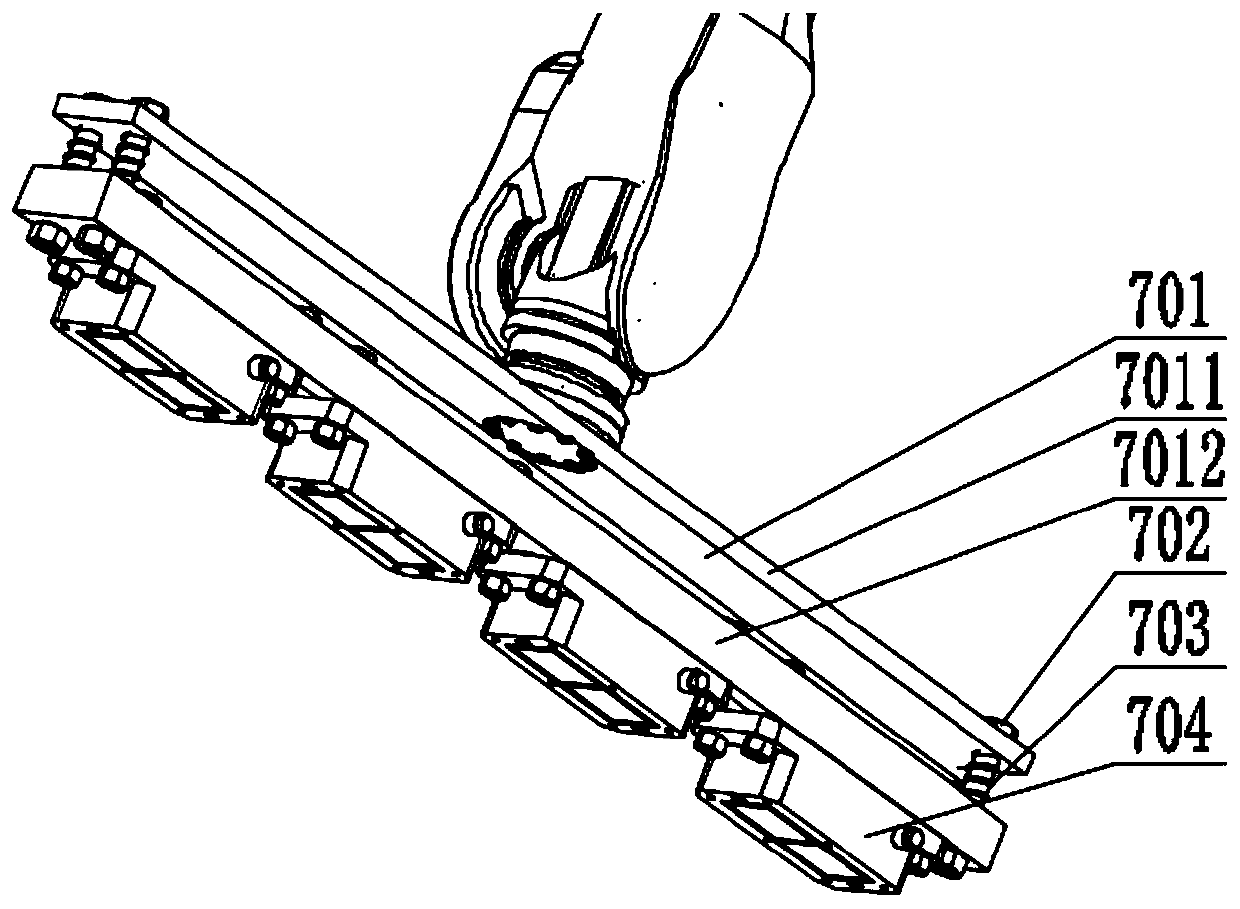

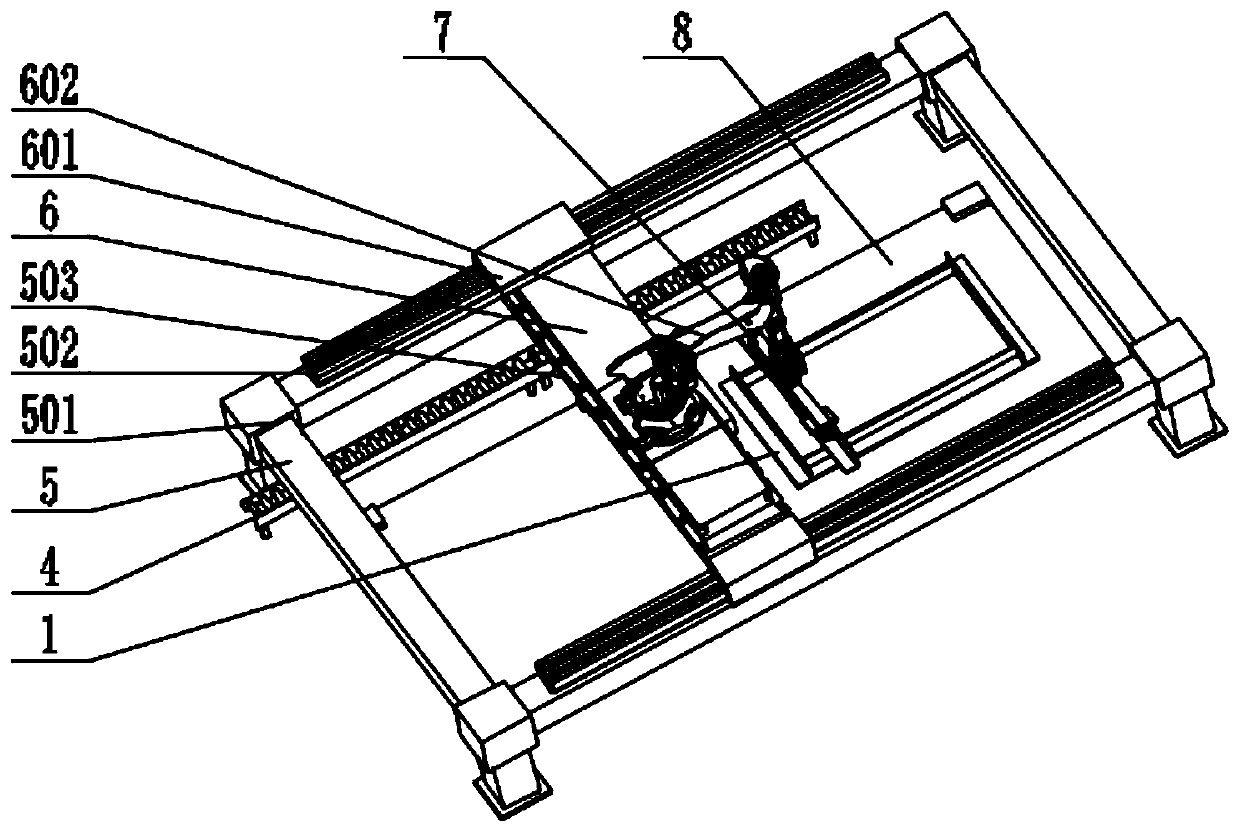

[0017] A mold distributing device for a concrete prefabricated component production line, which is composed of a side mold 1, a side mold storehouse 2, an inclined slide table 3, a conveying track 4, a truss 5, a mold distributing robot 6, an end clamp 7 and a mold table 8 , the side mold 1 is stored in the side mold library 2, the side mold library 1 is located on the upper side of the inclined slide table 3, the side mold outlet 201 faces the inclined slide table 3, and the conveying track 4 is located on the lower side of the inclined slide table 3. The truss 5 is located above the conveying track 4 and is structurally divided into a bracket 501, a slide rail 502 and a beam 503. The structure of the mold-clothing robot 6 is further divided into a walking axis 601 and a six-degree-of-freedom robot 602. The walking axis 601 Installed on the beam 503, the six-degree-of-freedom robot 602 is installed on the walking axis 601, and the end clamp 7 is located at the end of the sixth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com