Automatic material pushing device

A pusher, automatic technology, applied in forging/pressing/hammer devices, manufacturing tools, forging/pressing/hammering machinery, etc., can solve the problems of low efficiency and large labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

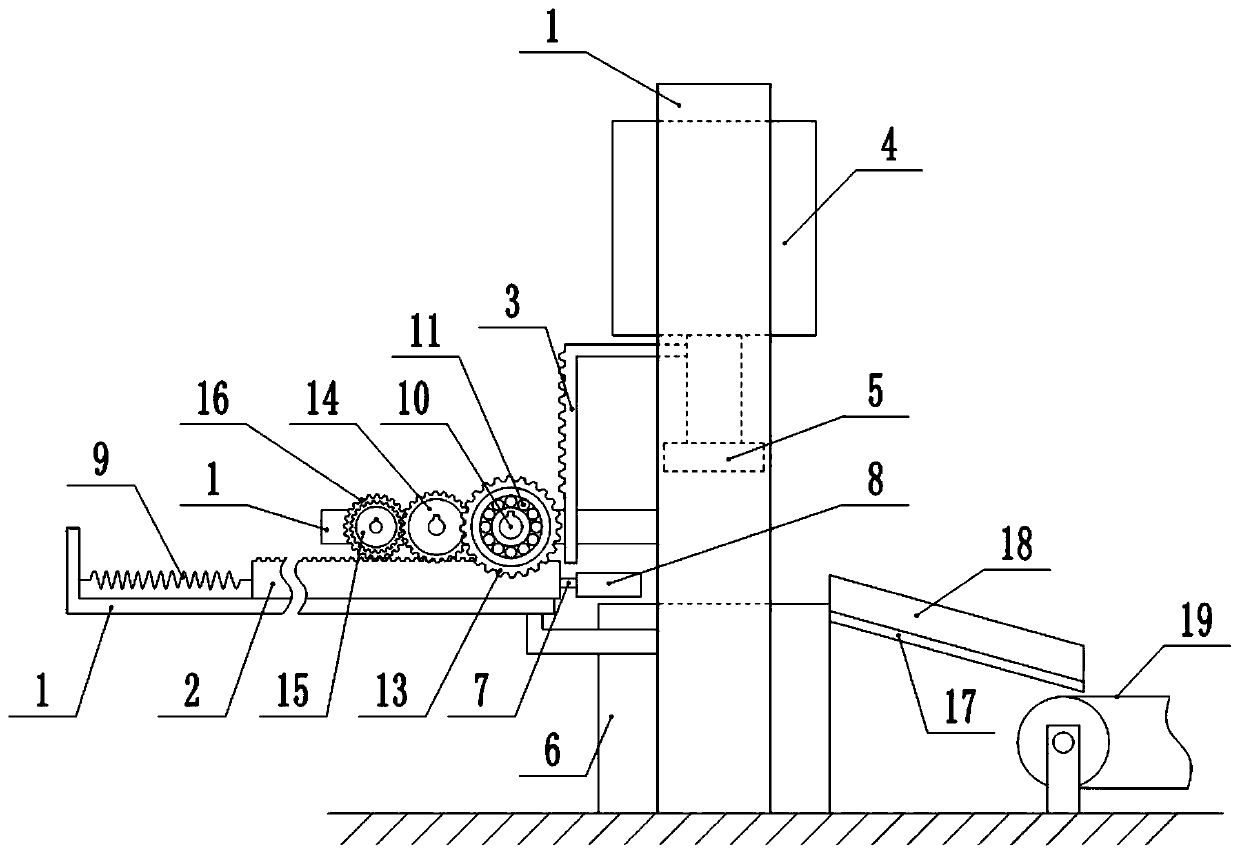

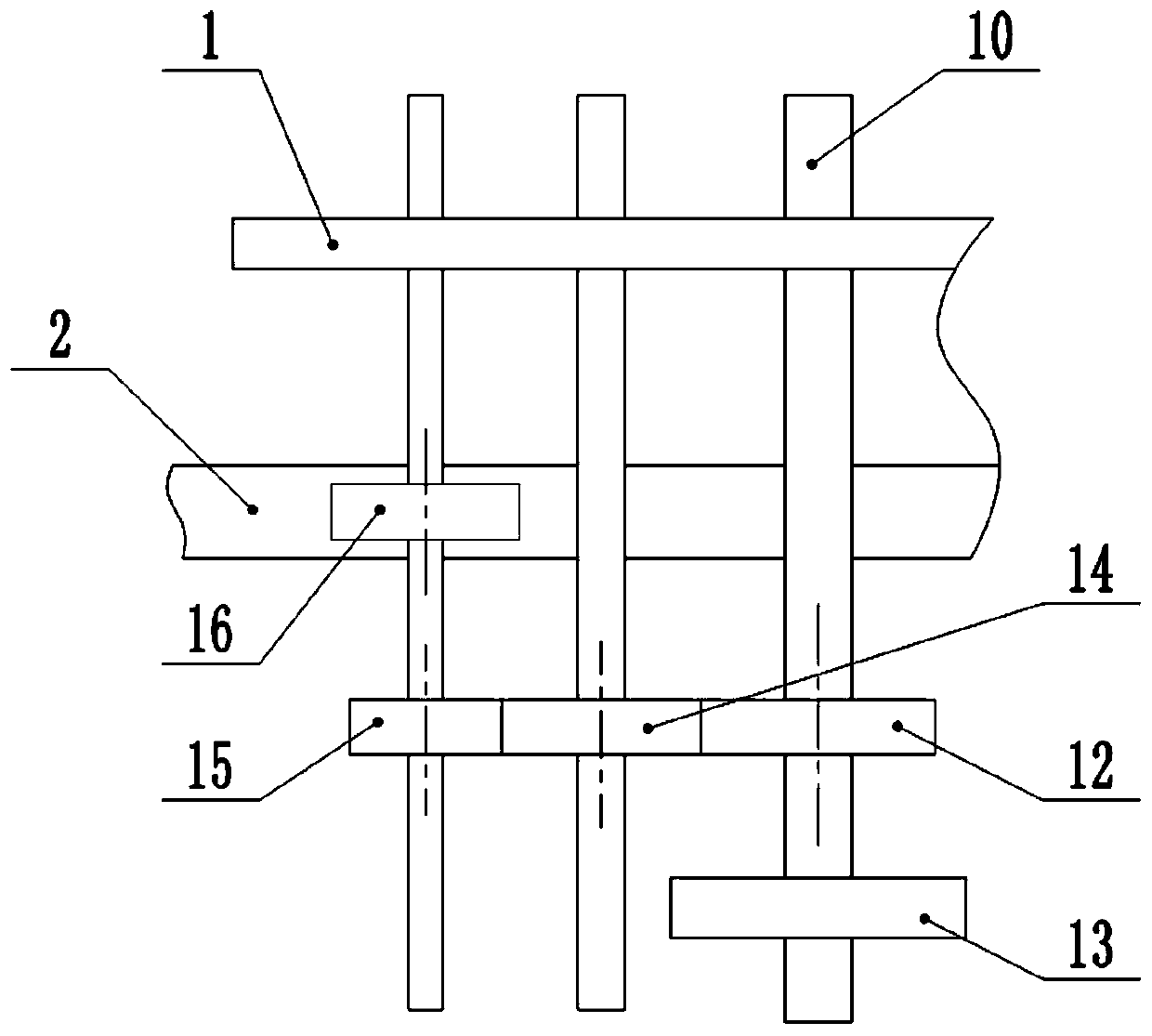

[0031] This embodiment is basically as figure 1 and figure 2 Shown: the automatic pushing device, including frame 1, the first rack 2 arranged horizontally and the second rack 3 arranged vertically, the punching machine 4 is fixedly connected to the frame 1, and the output end of the punching machine 4 is fixed A stamping head 5 is connected, and the stamping head 5 is located above the stamping table 6 .

[0032] The first rack 2 is horizontally slidably connected to the frame 1, the first rack 2 is higher than the stamping table 6, and the gap value between the bottom surface of the first rack 2 and the surface of the stamping table 6 is 3-5mm, this implementation In the example, the gap value is 4mm. The right end of the first rack 2 is fixedly connected with a push rod 7, and the right end of the push rod 7 is fixedly connected with a push plate 8. The push plate 8 is an arc-shaped plate, and the surface of the push plate 8 is coated with a release agent, thereby preven...

Embodiment 2

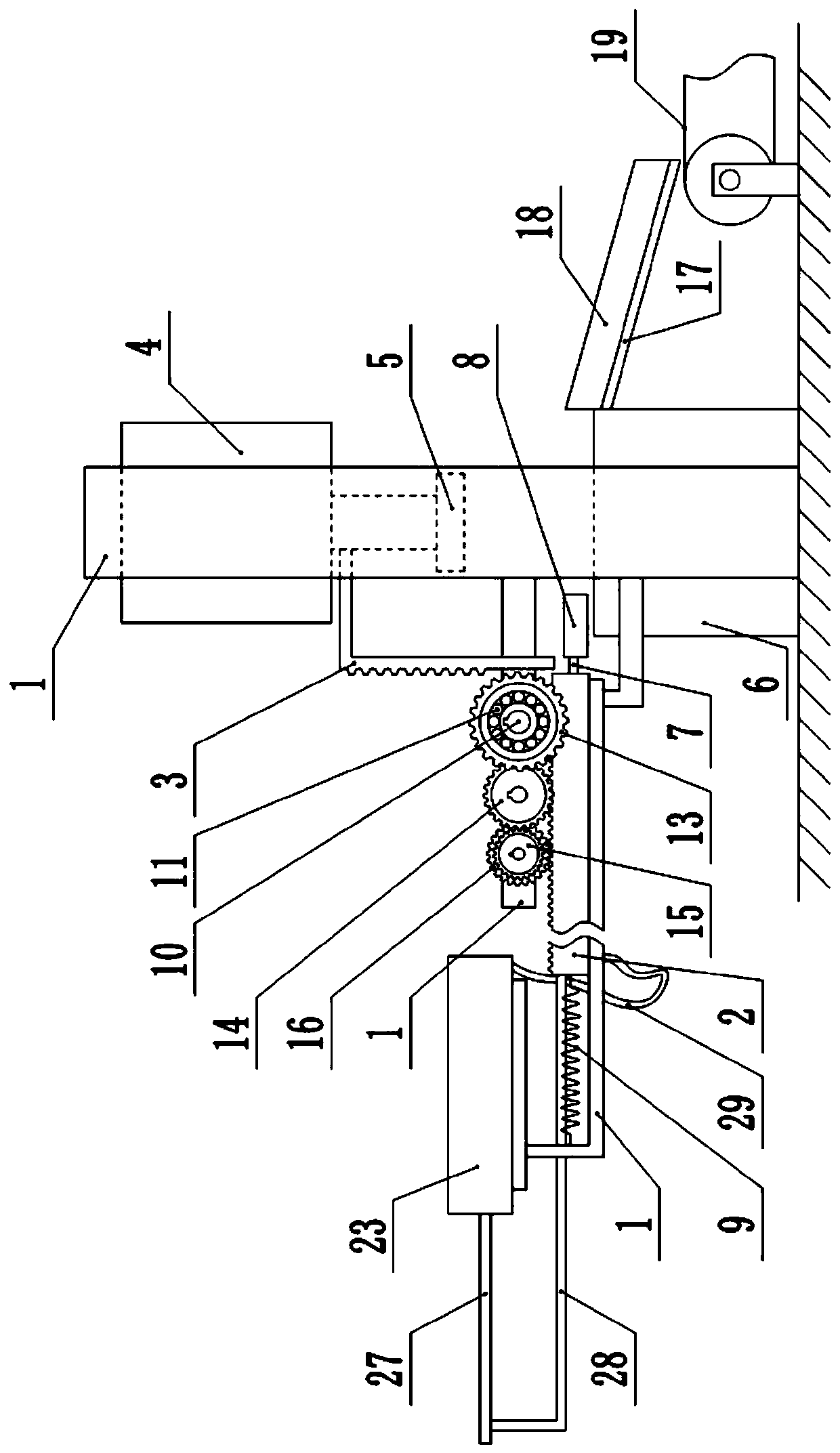

[0038] The difference between this embodiment and Embodiment 1 is that: image 3 and Figure 4 As shown, the inside of the first rack 2 is provided with a cavity, and a first piston 20 is slidably connected in the cavity, and the first piston 20 divides the cavity into a first left chamber 21 and a first right chamber 22, pushing The rod 7 extends into the first right chamber 22 and is connected with the first piston 20 .

[0039] A cylinder body 23 is fixedly connected to the frame 1, and a second piston 24 is slidably connected in the cylinder body 23. The second piston 24 divides the cylinder body 23 into a second left chamber 25 and a second right chamber 26. The second piston 24 is fixedly connected with a piston rod 27, the left end of the piston rod 27 is fixedly connected with a connecting rod 28, and the right end of the connecting rod 28 is fixedly connected with the first rack 2. The second right chamber 26 communicates with the first left chamber 21 through a hos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com