Sintering flue gas desulfurization system and sintering flue gas desulfurization method

A desulfurization system and sintering flue gas technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems that threaten the stable operation of the desulfurization system, equipment corrosion of the wet desulfurization system, and large sintering flue gas volume, etc. The effect of reducing system investment and operation cost, improving desulfurization reaction efficiency, and high reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

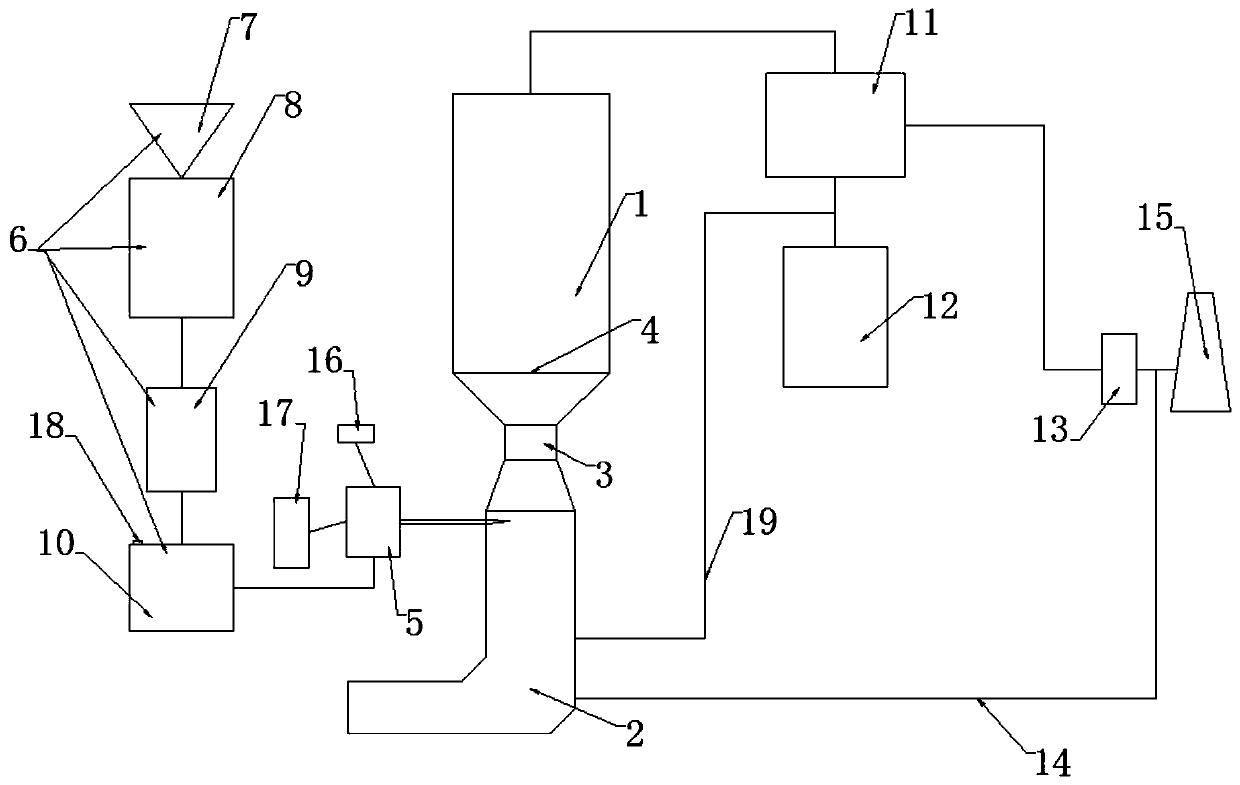

[0030] A sintering flue gas desulfurization system as an embodiment of the present invention, such as figure 1 As shown, the system includes a slaked lime slurry supply device 6, an air compression pump 16, a water storage tank 17, a three-fluid spray gun 5, a desulfurization tower 1, a dust removal device and a chimney 15;

[0031] The slaked lime slurry supply device 6 includes a quicklime bin 7, a quicklime digester 8, a desander 9 and a slurry tank 10, the outlet of the quicklime bin 7 communicates with the inlet of the quicklime digester 8, and the outlet of the quicklime digester 8 It is connected with the feed port of the desander 9, and the discharge port of the desander 9 is connected with the feed port of the slurry tank 10. The slurry tank 10 is provided with a process water inlet 18, and the discharge port of the slurry tank 10 is passed through a fluid pump. It communicates with the three-fluid spray gun 5, the air compression pump 16 communicates with the three-f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com