Tea leaf flexible processing system and technology capable of automatically selecting fixation manners

A technology of flexible processing and automatic selection, applied in tea processing before extraction, measuring devices, instruments, etc., can solve the problem of not selecting greening equipment, etc., and achieve the effects of stable product quality, maintenance and improvement, and reduction of labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

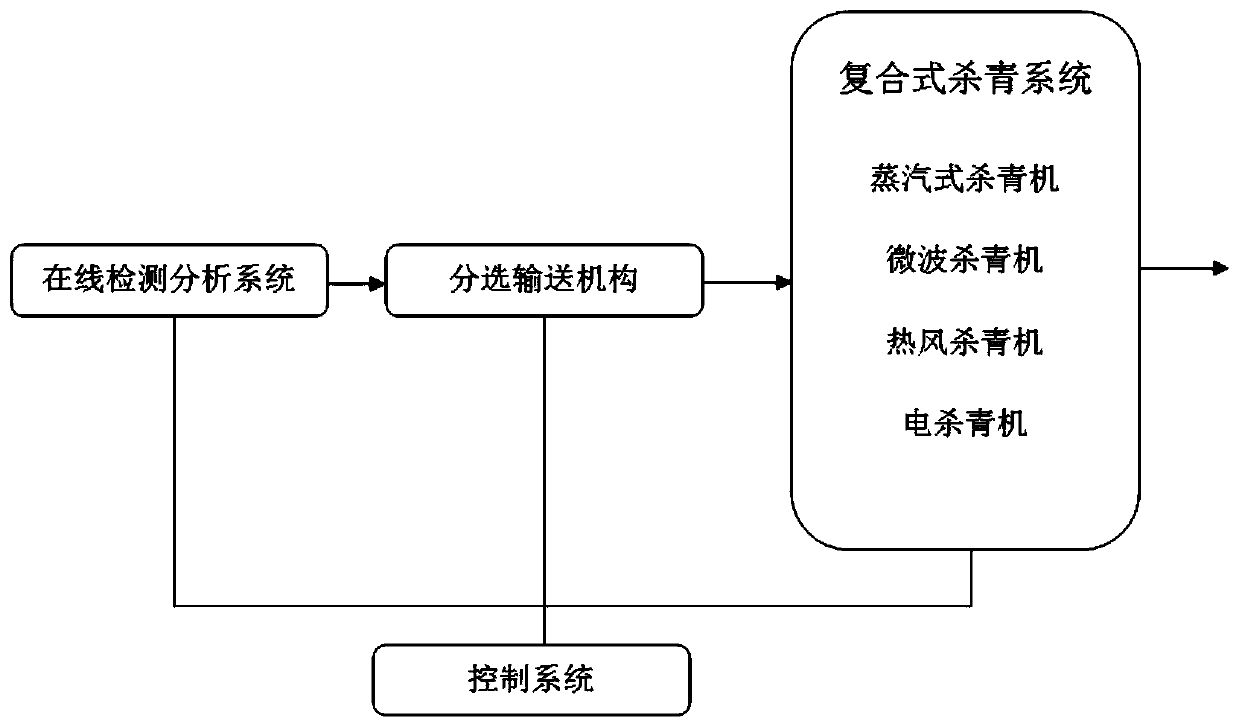

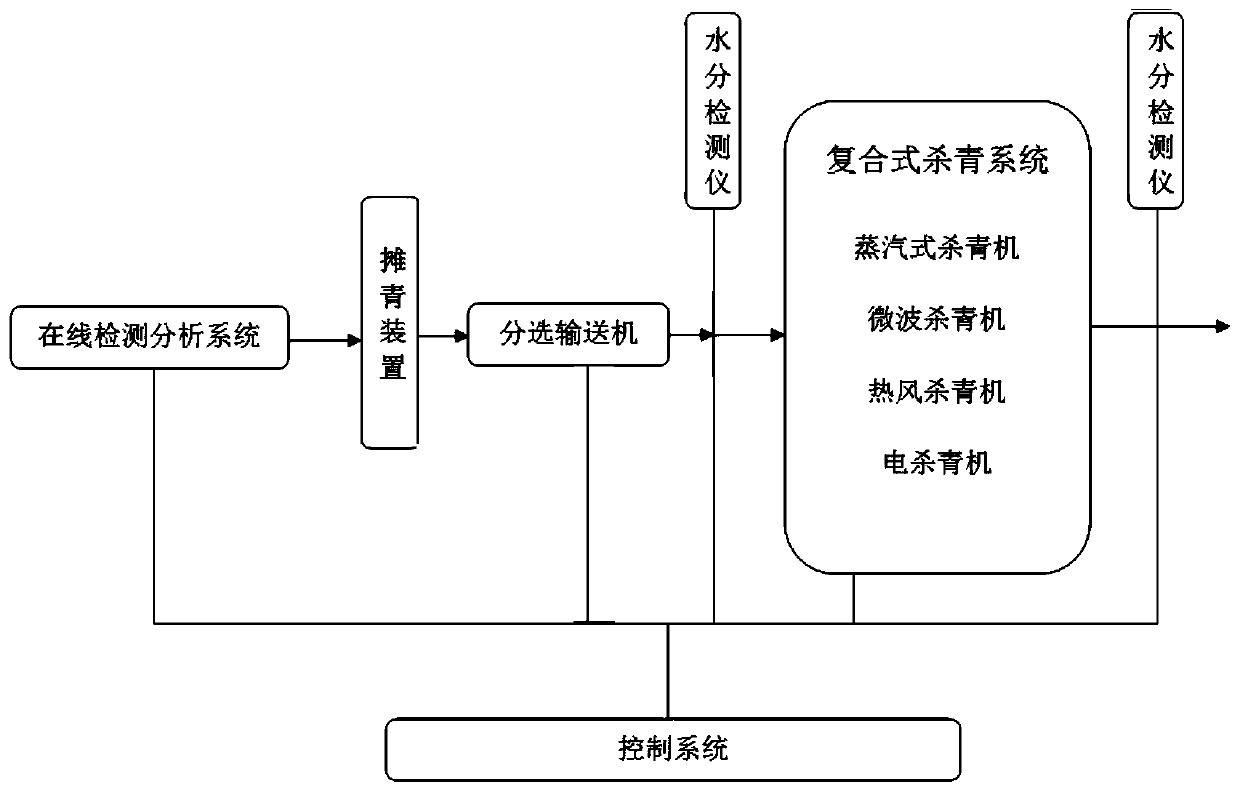

[0032] Such as figure 1 , figure 2As shown, a flexible tea processing system that automatically selects the greening method, including an online detection and analysis system, a composite greening system, a sorting and conveying mechanism, and a control system, wherein: the online detection and analysis system is used to detect and obtain the physical and chemical properties of tea materials. Index information and determine the physical and chemical evaluation results, and send it to the control system; the composite fixing system is used to finish the material, connected with the sorting and conveying mechanism, including at least two different ways of fixing machines, and can adjust and maintain the speed of the fixing machines Finishing process condition parameters; the finishing process conditions include one or more of the steam or microwave finishing temperature value, material moving speed or drum rotation speed, heating power of the finishing machine, feeding amount, ...

Embodiment 2

[0036] Embodiment 2: On the basis of Example 1, the sorting and conveying mechanism includes a steam de-encapsulation path, a microwave de-encapsulation path and a discharge path, the steam de-encapsulation path is connected to a constant flow feeding system and a steam de-enzyme machine, and the microwave de-encapsulation path is connected to a constant flow rate The feeding system and the microwave cleaning machine, the discharge path of the steam cleaning machine is also provided with a two-stage cleaning path, and the two-stage cleaning path is connected to the microwave killing path.

[0037] In actual use, a flexible tea processing system that automatically selects the greening method of the present invention controls the temporary storage and lifting device, the metering tube, and the belt conveyor by the controller to keep the incoming materials constant, and the moisture detection signals before and after the greening machine, Then give feedback to the greening machine...

Embodiment 3

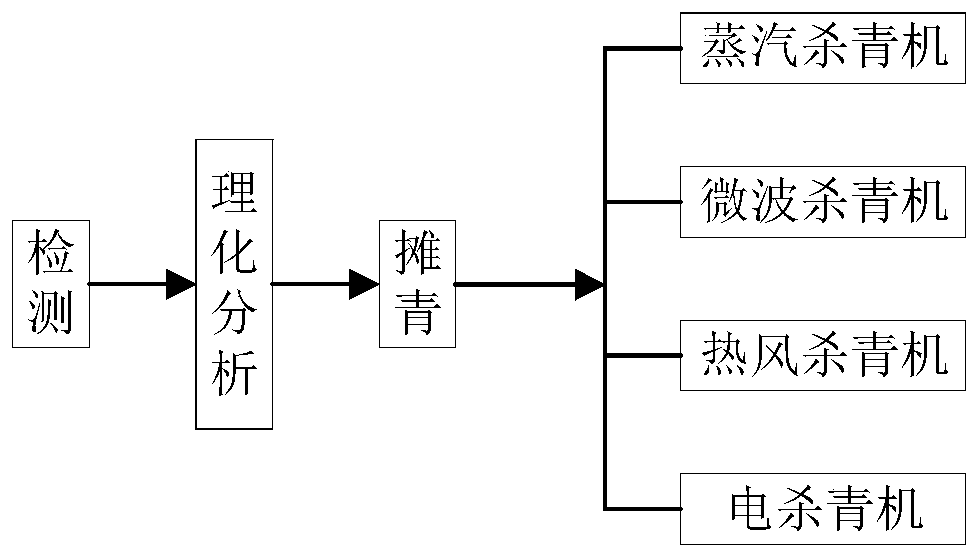

[0051] Embodiment 3: as Figure 2-4 As shown, a flexible tea processing technology that automatically selects the greening method includes: obtaining the physical and chemical index information of the tea material and judging the physical and chemical evaluation results; According to the information of the greening method, the sorting and conveying mechanism starts the path of the corresponding greening method, and the tea material enters the sorting and conveying mechanism at a constant flow; obtains the real-time moisture content MC1 of the material before entering the greening machine; obtains the water content of the material after finishing from the greening machine Real-time moisture content MC2; judge whether the value of real-time moisture content MC1 exceeds or is lower than the first preset value; judge whether the value of real-time moisture content MC2 exceeds or is lower than the second preset value; The operating parameters of the de-encapsulation system remain u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com