Isolating membrane and lithium ion battery

A technology of lithium-ion batteries and separators, applied in secondary batteries, battery pack components, circuits, etc., can solve the problems of reducing the overall safety of lithium-ion batteries and insufficient safety of lithium-ion batteries, and achieve strength improvement and improvement performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

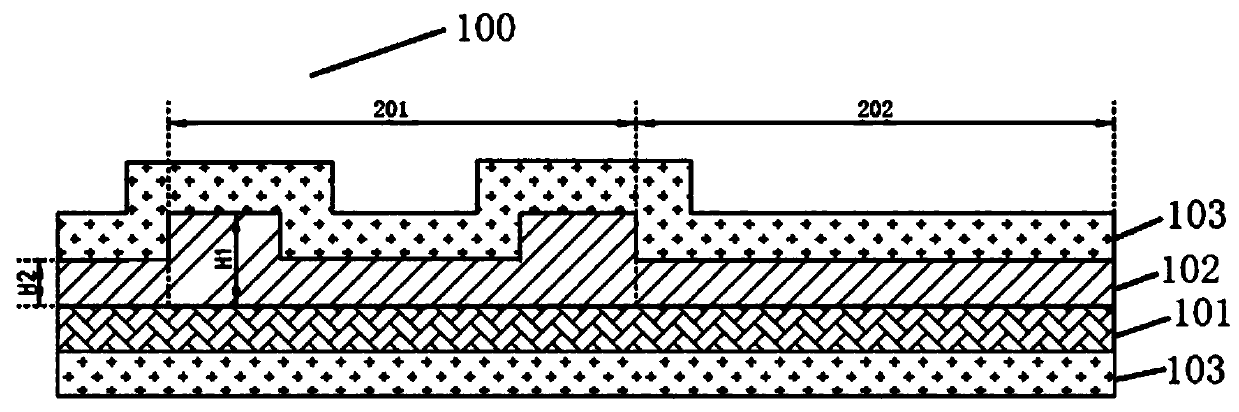

Embodiment 1

[0075] (1) Preparation of positive pole piece:

[0076] The cathode material lithium cobalt oxide (LiCoO 2 ), the conductive agent Super P, and the binder polyvinylidene fluoride are mixed according to the weight ratio of 97.8:1:1.2, N-methylpyrrolidone (NMP) is added, and stirred under the action of a vacuum mixer until the system becomes uniform and transparent, and the obtained positive electrode slurry, wherein the solid content of the positive electrode slurry is 77wt%; the positive electrode slurry is evenly coated on the aluminum foil of the positive electrode current collector; After being stripped, it was dried under vacuum conditions at 85° C. for 4 hours to obtain a positive electrode sheet.

[0077] (2) Negative electrode sheet preparation:

[0078] Mix the negative electrode material artificial graphite, conductive agent Super P, thickener sodium carboxymethylcellulose (CMC), and binder styrene-butadiene rubber (SBR) in a weight ratio of 97.7:1:0.3:1, add deioni...

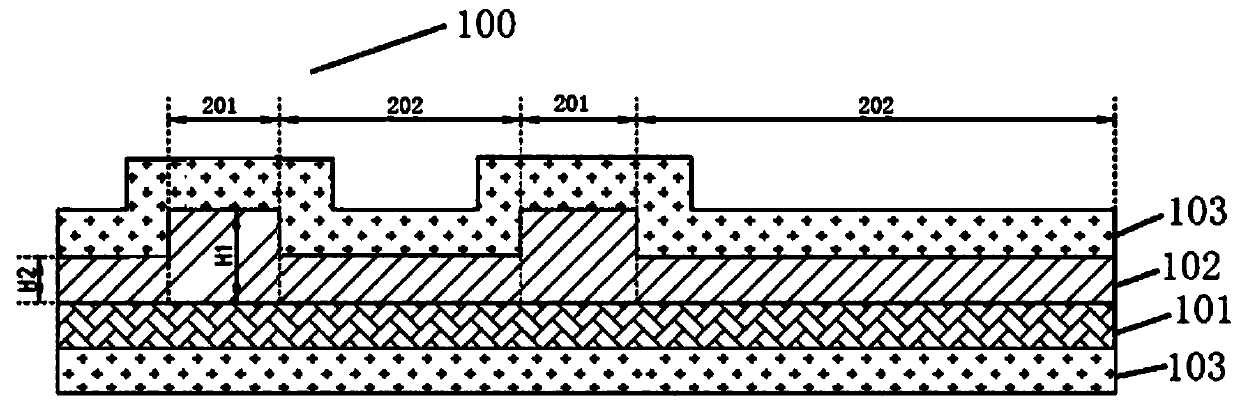

Embodiment 2

[0087] The preparation process of the lithium-ion battery is the same as in Example 1, the difference is that the thickness of the first coating in the first region only includes the first thickness, such as figure 2 shown.

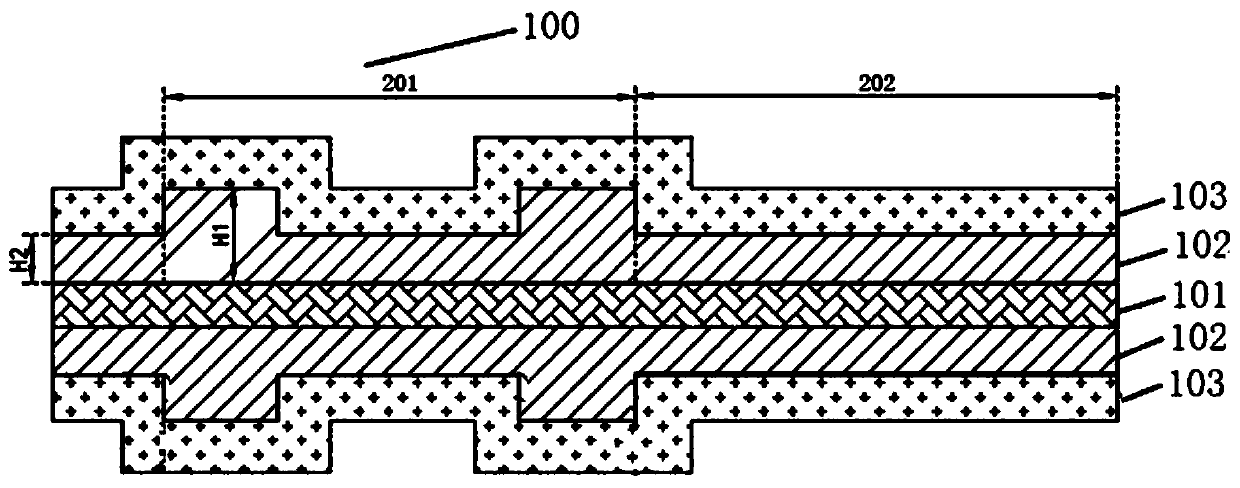

Embodiment 3

[0089] The preparation process of the lithium-ion battery is the same as in Example 1, except that the first coating slurry is coated on both sides of a 7 μm thick porous substrate (polyethylene).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com