Surface emissivity online testing device and method thereof

A surface emissivity and on-line testing technology, which is applied to measuring devices, radiation pyrometry, electric radiation detectors, etc., can solve the problem of complex structure of the measurement process and devices, high requirements for temperature and heat capacity accuracy, and inability to complete the measurement online and other problems, to achieve the effect of easy on-site testing, short measurement time and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

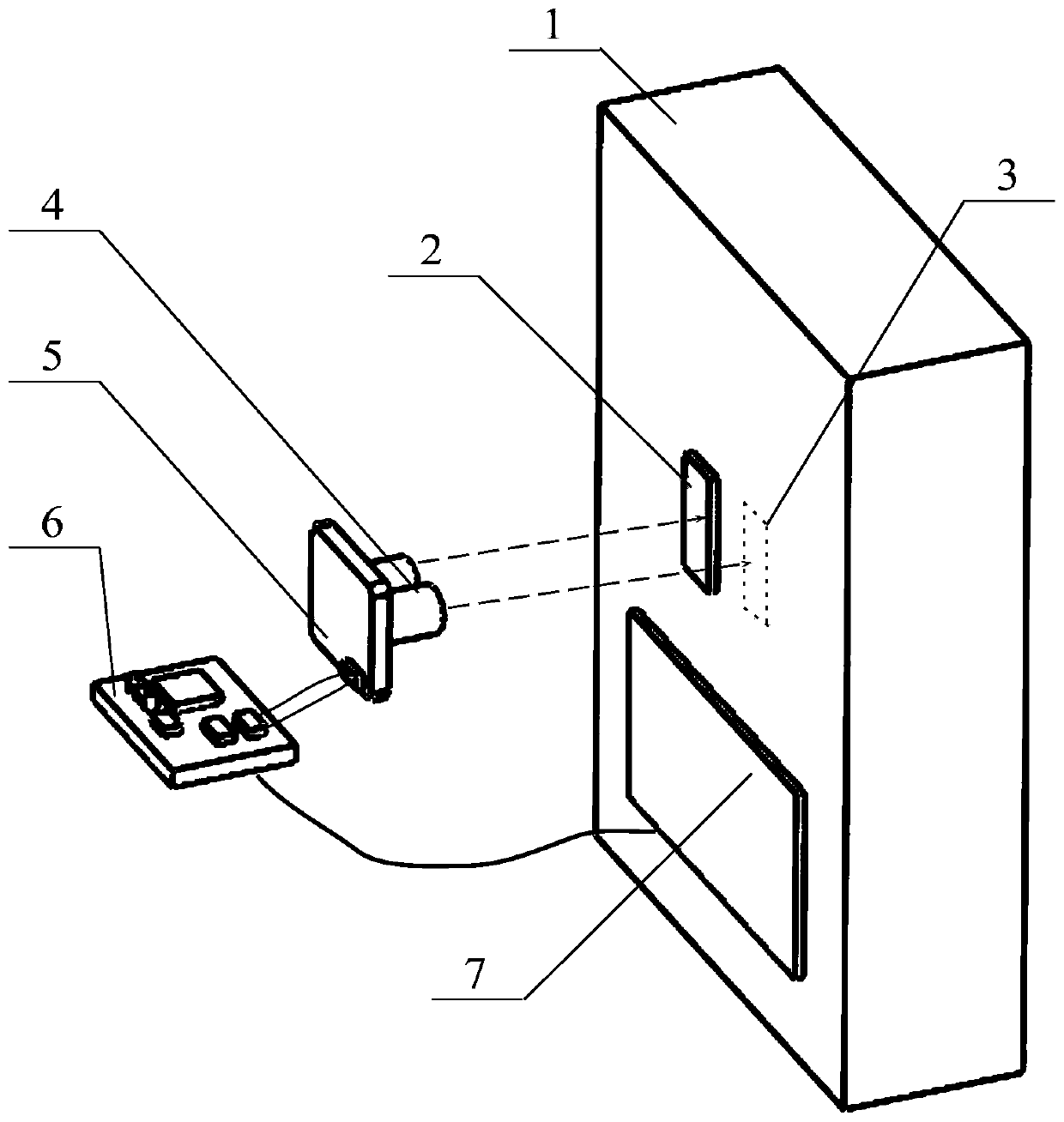

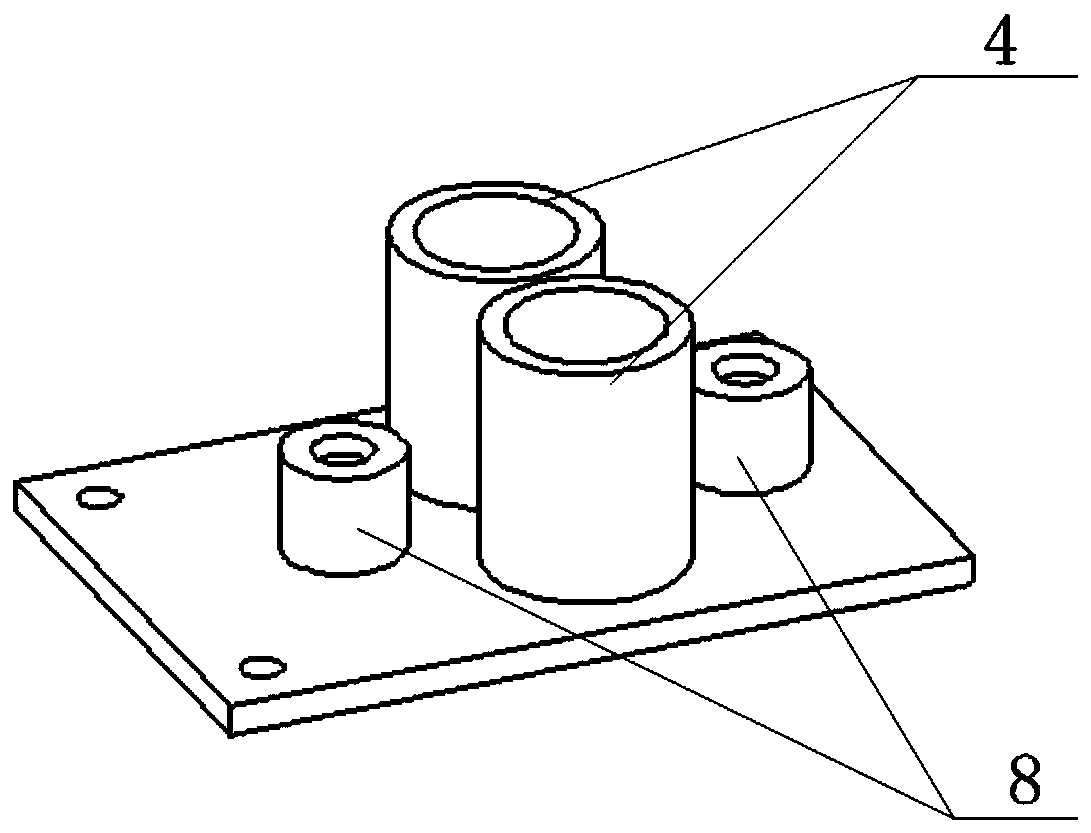

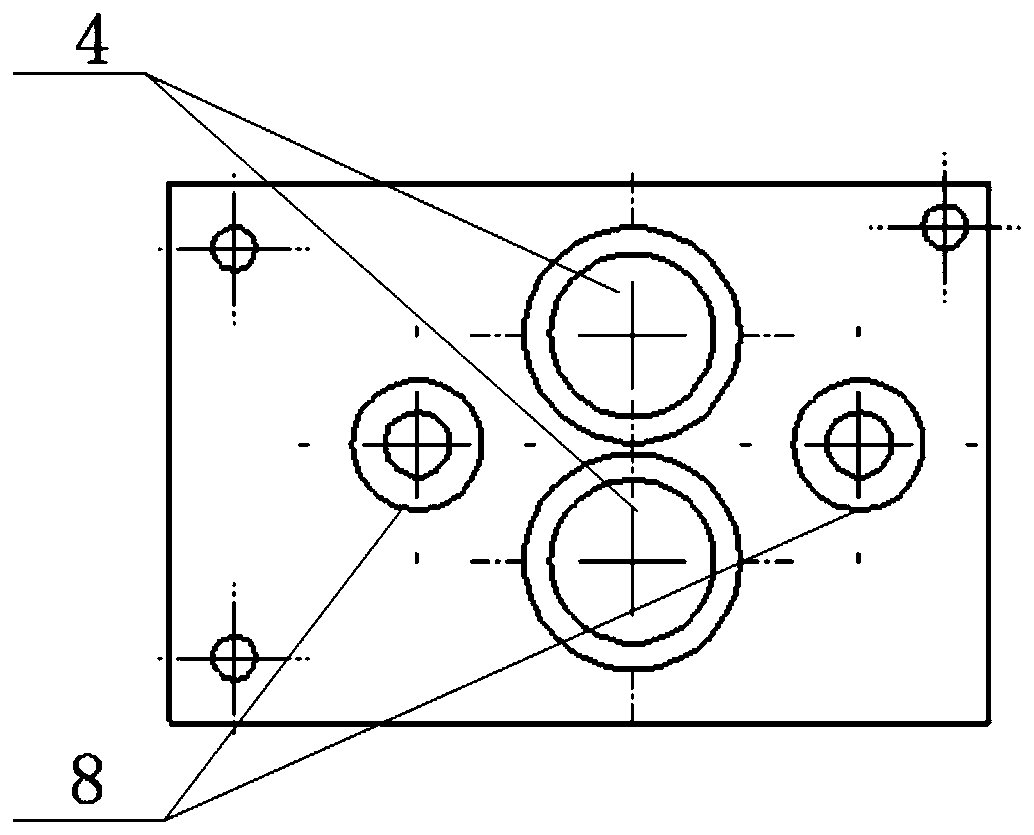

[0040] like Figure 1 ~ Figure 3 Shown, a surface emissivity online testing device, the device includes:

[0041] Film 2 with calibrated emissivity: attached to the target object 1 to be measured near the local surface 3 to be measured during the test;

[0042] Heating unit 7: increase the surface temperature of the measured target object 1 during testing;

[0043] Sensor module 5: synchronously measure the infrared radiation on the surface of the film 2 and the local surface 3 to be measured on the target object 1 to be measured and convert it into temperature information, and simultaneously obtain the temperature information of the sensor module 5 itself;

[0044] Control processing unit 6: connect the heating unit 7 and the sensor module 5 for power supply and data output, and obtain the emissivity of the local surface 3 to be measured on the measured target object 1 according to the acquired temperature information.

[0045] The thickness of the film 2 is less than 1mm, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com