Construction method of assembly and launch in shield tunnel

A technology of shield tunneling and construction method, which is applied in the direction of tunnels, tunnel linings, shaft equipment, etc., can solve the problems of occupying social living space, long construction period, and large-scale demolition, so as to avoid large-scale demolition, reduce actual consumption, The effect of avoiding technical risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0034] The construction method of assembling and starting in the shield tunnel hole comprises the following steps:

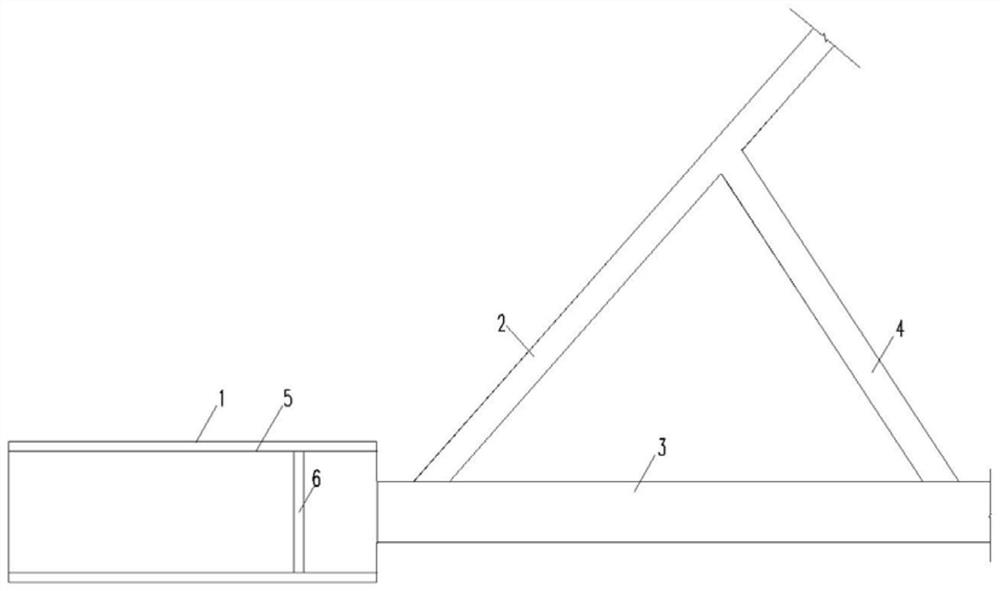

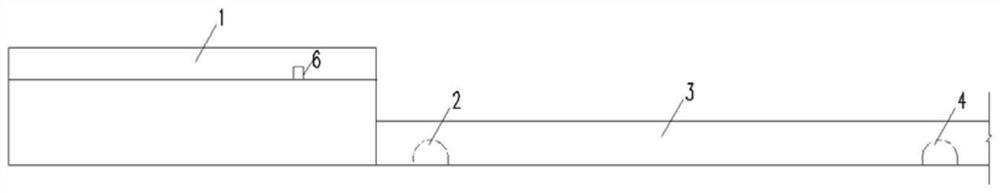

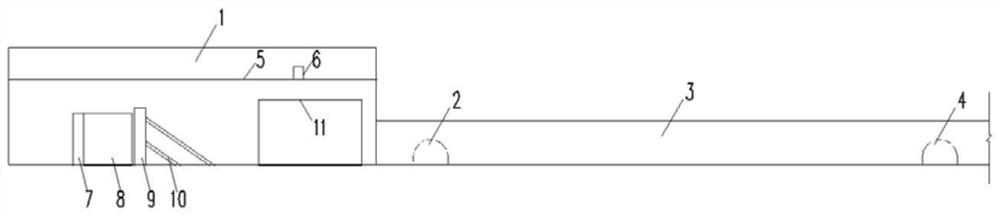

[0035] ① On the starting shore, design and assemble the starting cavern 1, the inclined shaft 2, the branch tunnel 4 and the main line tunnel 3 in combination with the engineering needs and the shield tunneling needs. Design requirements: such as figure 1 As shown, the front end and assembly of the main line tunnel 3 are docked with the rear end of the starting cavern 1, the inclined shaft 2 is connected to the main line tunnel 3 at a plane intersection angle of 30°-60°, and the slope of the inclined shaft 2 is not greater than 10%; The branch tunnel 4 is connected to the main line tunnel 3 at a plane inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com