Installation structure and installation method of a wall insulation board

A technology of installation structure and installation method, which is applied in the direction of thermal insulation, building components, building structure, etc., can solve the problems of hidden safety hazards, easily damaged surface safety hazards, complicated installation process, etc., saving construction period, simple and fast installation method, The effect of simplifying the installation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

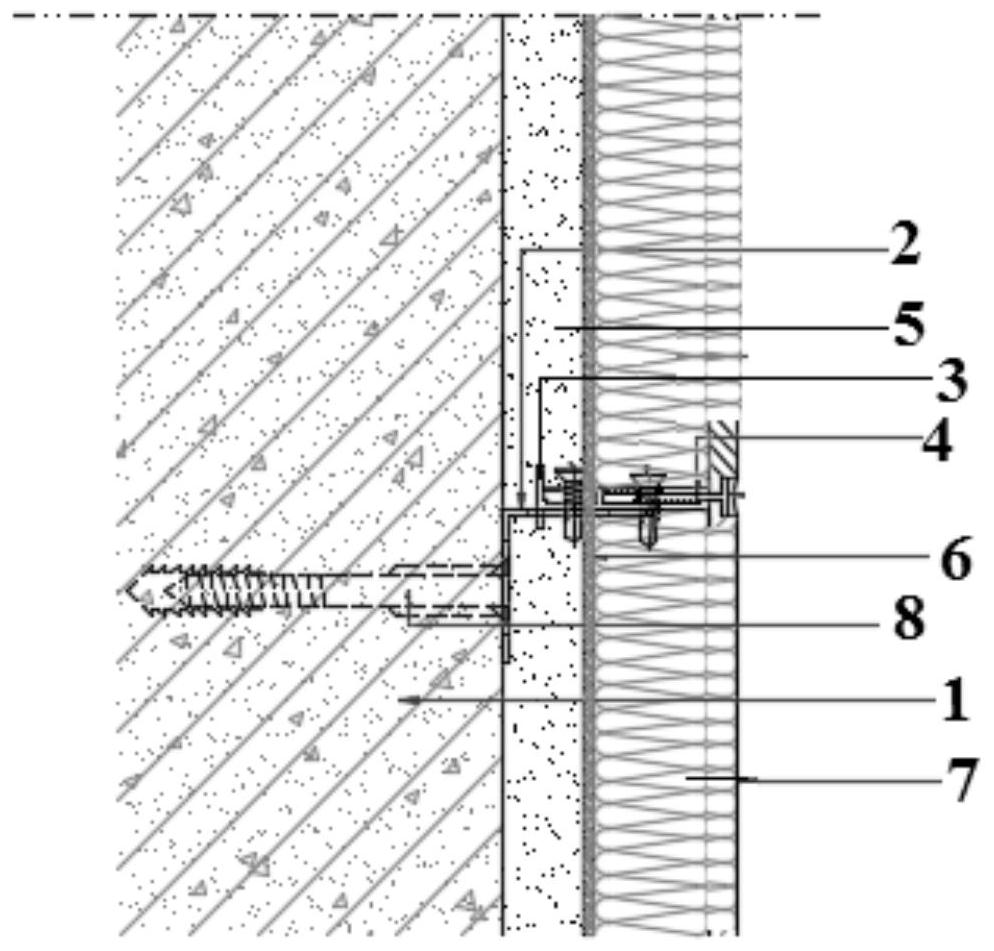

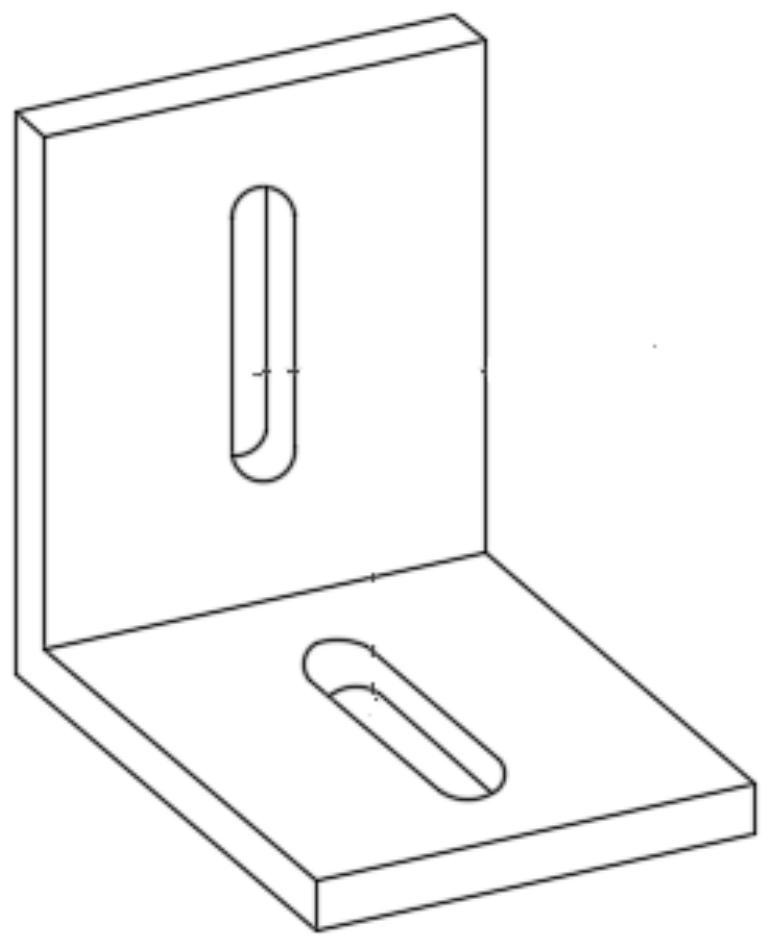

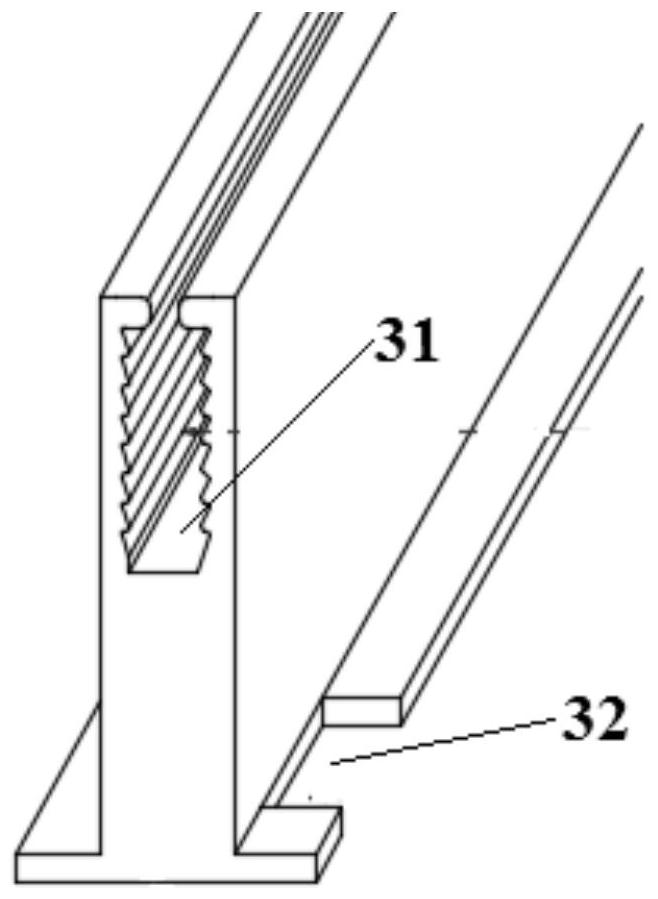

[0080] This embodiment provides an installation structure of a wall insulation board, the schematic diagram of the installation structure is as follows figure 1 As shown, it includes an L-shaped adapter 2, a T-shaped guide rail 3, a T-shaped fixture 4 and a thermal insulation board 7. The L-shaped adapter 2 includes planes and elevations perpendicular to each other, and the T-shaped guide rail 3 The main body is provided with a card slot 31, at least one of the two wings of the T-shaped guide rail 3 is provided with a groove 32, and the edge of the surface layer of the thermal insulation board 7 is grooved;

[0081] The facade of the L-shaped adapter 2 is closely attached to and fixed on the wall 1, the plane is perpendicular to the wall 1, the groove 32 on the T-shaped guide rail 3 clamps the plane of the L-shaped adapter 2, The two wings of the T-shaped guide rail 3 are parallel to the wall 1, the main body of the T-shaped guide rail 3 is fixedly connected to the plane of th...

Embodiment 2

[0089] This embodiment provides an installation structure of a wall insulation board. The installation structure includes an L-shaped adapter 2, a T-shaped guide rail 3, a T-shaped fixing member 4 and an insulation board 7. The L-shaped adapter 2 Including planes and elevations perpendicular to each other, the main part of the T-shaped guide rail 3 is provided with a slot 31, at least one of the two wings of the T-shaped guide rail 3 is provided with a groove 32, and the edge of the surface layer of the thermal insulation board 7 is grooved;

[0090] The facade of the L-shaped adapter 2 is closely attached to and fixed on the wall 1, the plane is perpendicular to the wall 1, the groove 32 on the T-shaped guide rail 3 clamps the plane of the L-shaped adapter 2, The two wings of the T-shaped guide rail 3 are parallel to the wall 1, the main body of the T-shaped guide rail 3 is fixedly connected to the plane of the L-shaped adapter 2, and the wall 1 is provided with a leveling lay...

Embodiment 3

[0097] This embodiment provides a method for installing a wall insulation board. The method can obtain the installation structure in Embodiment 1, including the following steps:

[0098] (1) First pop up the vertical control line and the horizontal control line on the wall 1, and fix the L-shaped adapter 2 to the wall 1 through the hole provided on the facade of the L-shaped adapter 2 with the expansion bolt 8 , and then the groove 32 provided on one wing of the T-shaped guide rail 3 is clamped on the plane of the L-shaped adapter 2, so that the two wings of the T-shaped guide rail 3 are parallel to the wall 1, and then the T-shaped guide rail 3 is connected with self-tapping screws. The L-shaped adapter 2 is fixedly connected, and the self-tapping screw passes through the main body of the T-shaped guide rail 3 and the hole on the plane of the L-shaped adapter 2, and then the subsequent L-shaped adapter is installed in the same way according to the sprung control line. Connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com