Construction method of deep water foundation pit cofferdam for large bridge foundation

A construction method and deep-water foundation technology, applied in infrastructure engineering, construction, etc., can solve the problems of heavy weight of double-wall steel cofferdam, high height of double-wall steel cofferdam, difficulty in construction of deep-water foundation pit cofferdam for large-scale bridge foundations, etc. , to achieve the effect of reducing transportation and installation pressure, improving sealing performance, and improving butt joint strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0038] refer to figure 1 , is a double-wall steel cofferdam 1 disclosed in the present invention, comprising a lower cofferdam 11 and an upper cofferdam 12 . Among them, the lower cofferdam 11 is 16.2 meters; the upper cofferdam 12 is 9.8 meters, that is, the total height of the double-wall steel cofferdam 1 is 26 meters.

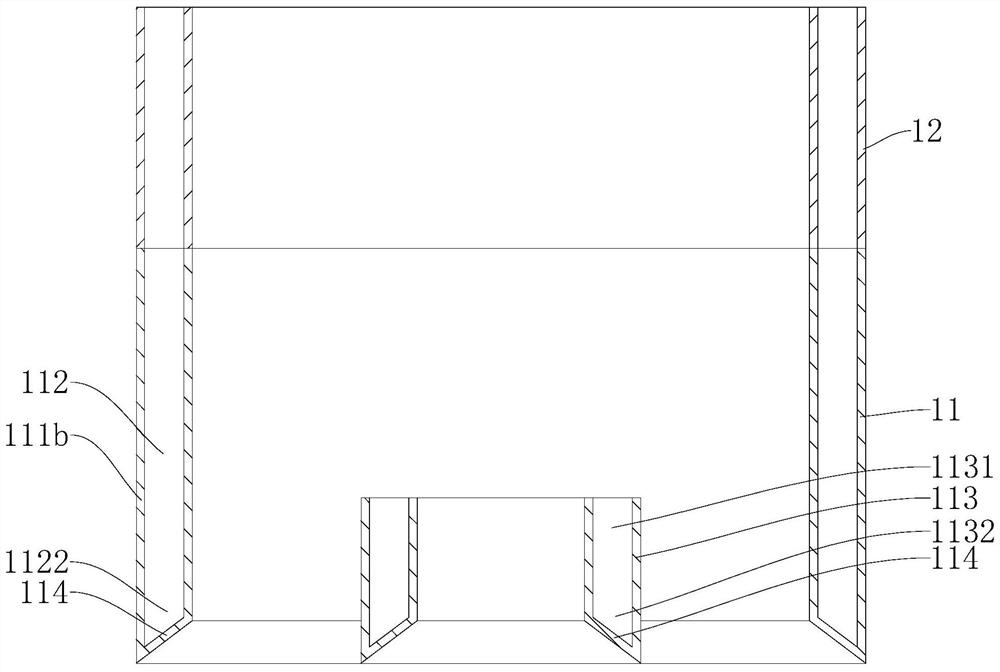

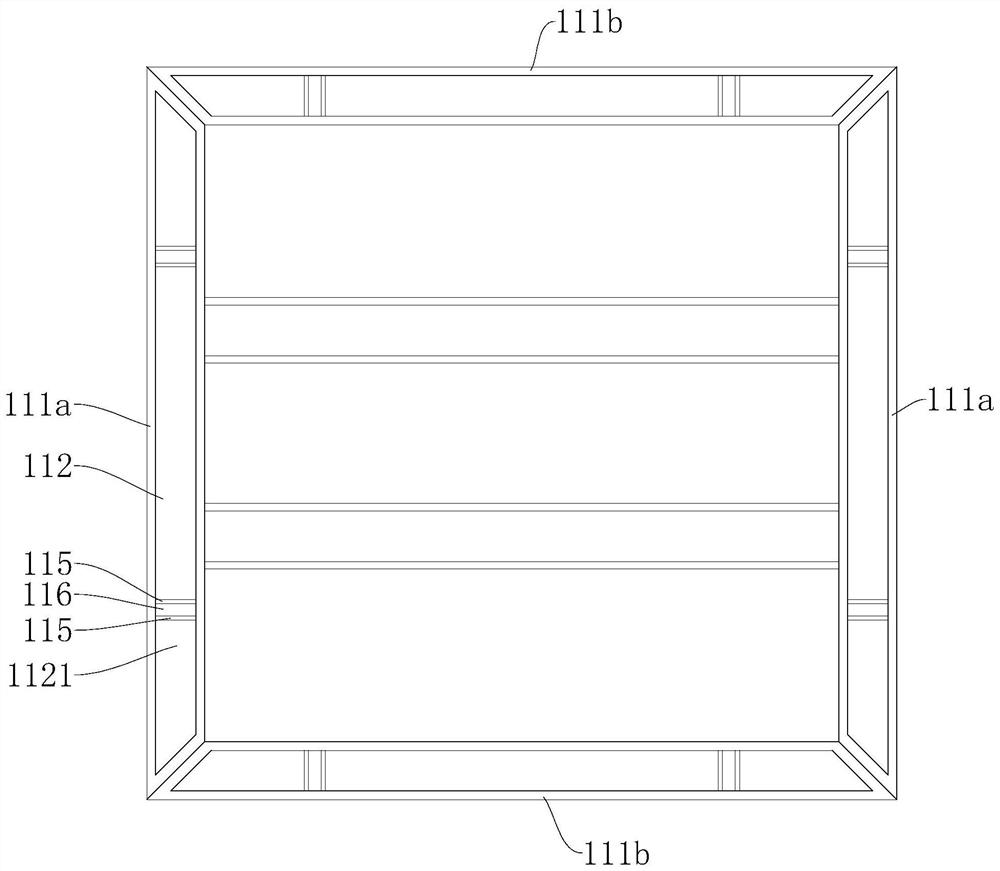

[0039] refer to figure 2 and image 3 , the lower cofferdam 11 is a square cofferdam, including a lower long weir wall 111a arranged oppositely, two lower short weir walls 111b arranged oppositely, and two pieces connected between the two lower long weir walls 111a and parallel to the lower short weir The partition wall 113 of the wall 111b.

[0040] Both the bottom ends of the lower long weir wall 111a and the lower short weir wall 111b are provided with blade feet 114 . Both the lower long weir wall 111 a and the lower short weir w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com