Permeable and drainage asphalt pavement paving structure

A technology of asphalt pavement, permeable drainage, applied to roads, roads, building components, etc., can solve problems such as insufficient carrying capacity, achieve high structural carrying capacity, good noise reduction effect, and reduce the effect of heat island effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

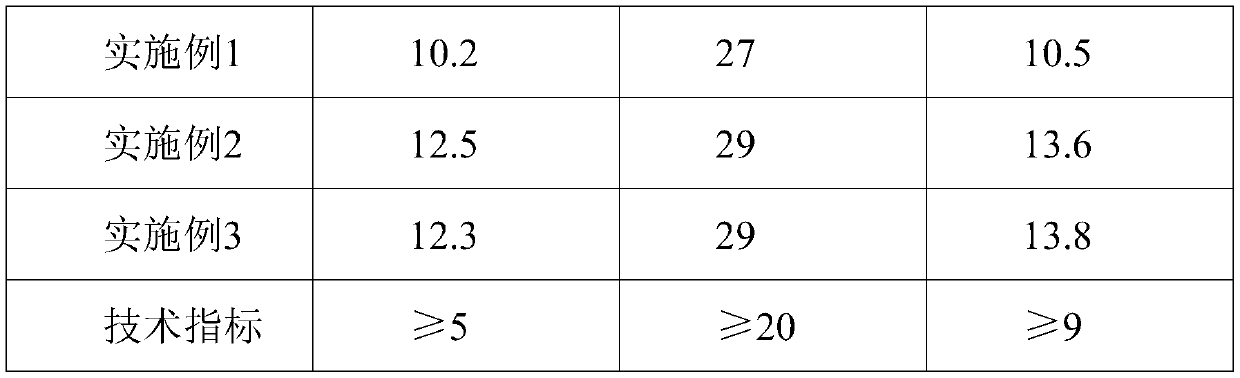

Embodiment 1

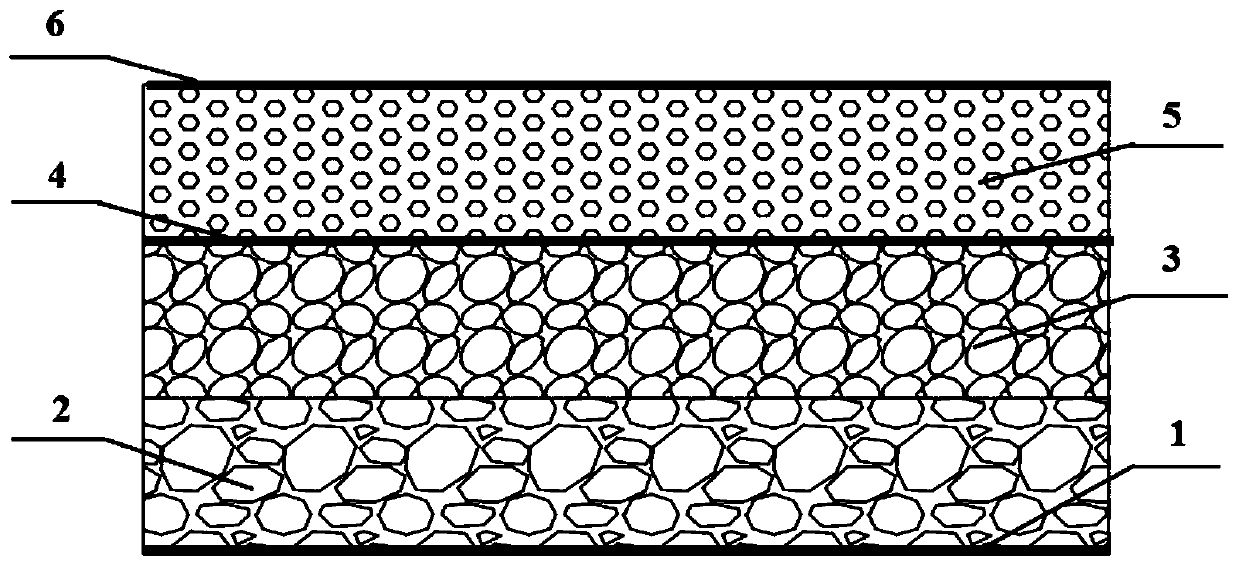

[0028] Example 1: A pavement structure of permeable and drainage asphalt pavement, from the top surface of the base, from bottom to top are waterproof adhesive layer 1, high-viscosity modified asphalt concrete PAC-13 lower layer 2, low-volume epoxy asphalt Concrete PAC-10 middle surface layer 3, filter layer 4, high viscosity modified asphalt concrete PAC-5 upper layer 5, heat insulation layer 6.

[0029] Its preparation method comprises the following steps:

[0030] (1) First clean the top surface of the base, and then spread the emulsified asphalt waterproof bonding layer, the spreading amount is 0.5kg / m 2 ~0.6kg / m 2 After the emulsified asphalt is broken, pave the lower layer of high-viscosity modified asphalt concrete PAC-13.

[0031] Among them, the emulsified asphalt is prepared by modifying first and then emulsifying. The emulsifier content is 2.0%, the stabilizer content is 0.1%, and the oil-water ratio is 60:40. The thickness of the lower layer of high-viscosity mo...

Embodiment 2

[0042] Embodiment 2: A pavement structure of permeable and drainage asphalt pavement, from the top surface of the base, from bottom to top are waterproof adhesive layer 1, high-viscosity modified asphalt concrete PAC-13 lower layer 2, low-volume epoxy asphalt Concrete PAC-10 middle surface layer 3, filter layer 4, high viscosity modified asphalt concrete PAC-5 upper layer 5, heat insulation layer 6.

[0043] Its preparation method comprises the following steps:

[0044] (1) First clean the top surface of the base, and then spread the emulsified asphalt waterproof bonding layer, the spreading amount is 0.5kg / m 2 ~0.6kg / m 2 After the emulsified asphalt is broken, pave the lower layer of high-viscosity modified asphalt concrete PAC-13.

[0045] Among them, the emulsified asphalt is prepared by modifying first and then emulsifying. The emulsifier content is 2.0%, the stabilizer content is 0.1%, and the oil-water ratio is 60:40. The thickness of the lower layer of high-viscosity...

Embodiment 3

[0056] Example 3: A pavement structure of permeable and drainage asphalt pavement, from the top surface of the base, from bottom to top are waterproof adhesive layer 1, high-viscosity modified asphalt concrete PAC-13 lower layer 2, low-volume epoxy asphalt Concrete PAC-10 middle surface layer 3, filter layer 4, high viscosity modified asphalt concrete PAC-5 upper layer 5, heat insulation layer 6.

[0057] Its preparation method comprises the following steps:

[0058] (1) First clean the top surface of the base, and then spread the emulsified asphalt waterproof bonding layer, the spreading amount is 0.5kg / m 2 ~0.6kg / m 2 After the emulsified asphalt is broken, pave the lower layer of high-viscosity modified asphalt concrete PAC-13.

[0059] Among them, the emulsified asphalt is prepared by modifying first and then emulsifying. The emulsifier content is 2.0%, the stabilizer content is 0.1%, and the oil-water ratio is 60:40. The thickness of the lower layer of high-viscosity mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface thickness | aaaaa | aaaaa |

| Maximum nominal particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com