Battery sheet pressure welding device, battery string pressure welding device and welding method thereof

A cell and battery technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problem that solar cells are difficult to ensure the uniformity of welding, to reduce welding dead spots, precise level adjustment, and improve welding. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

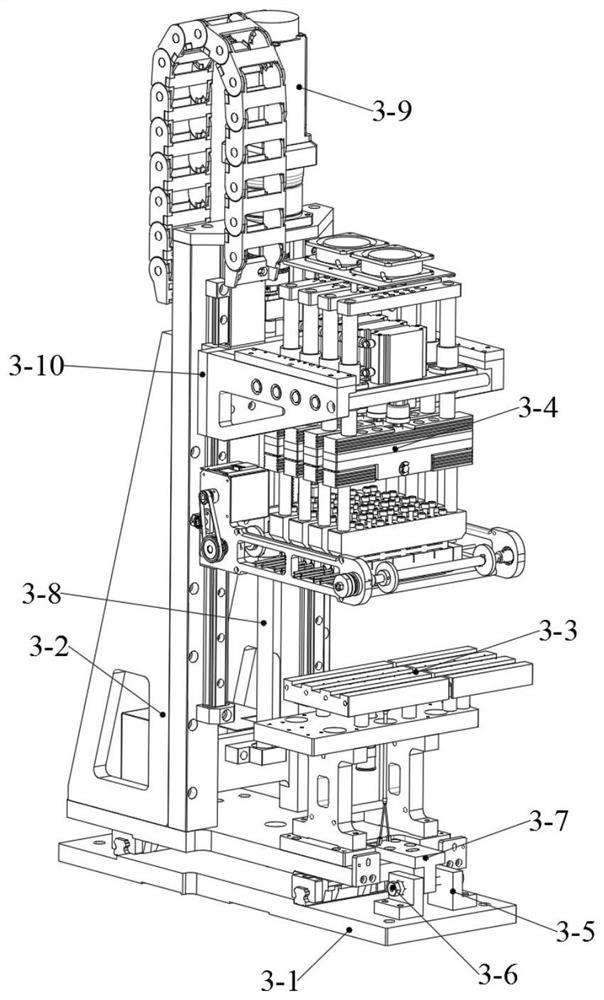

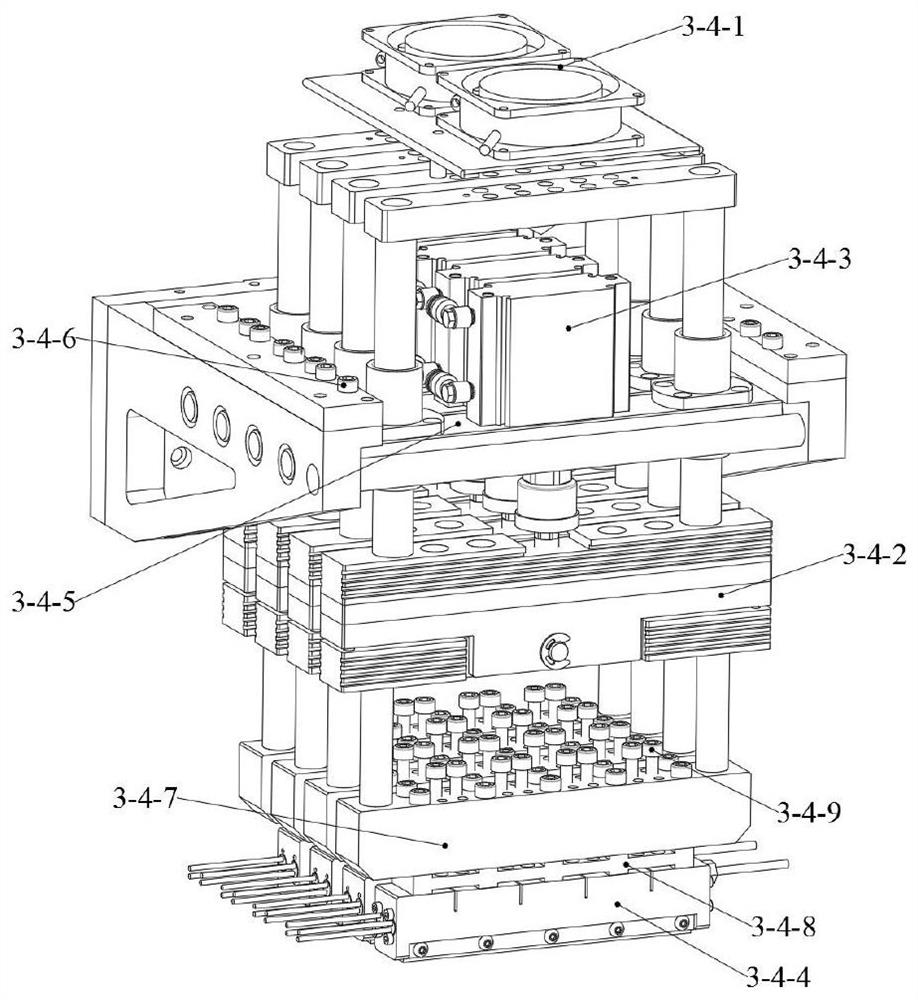

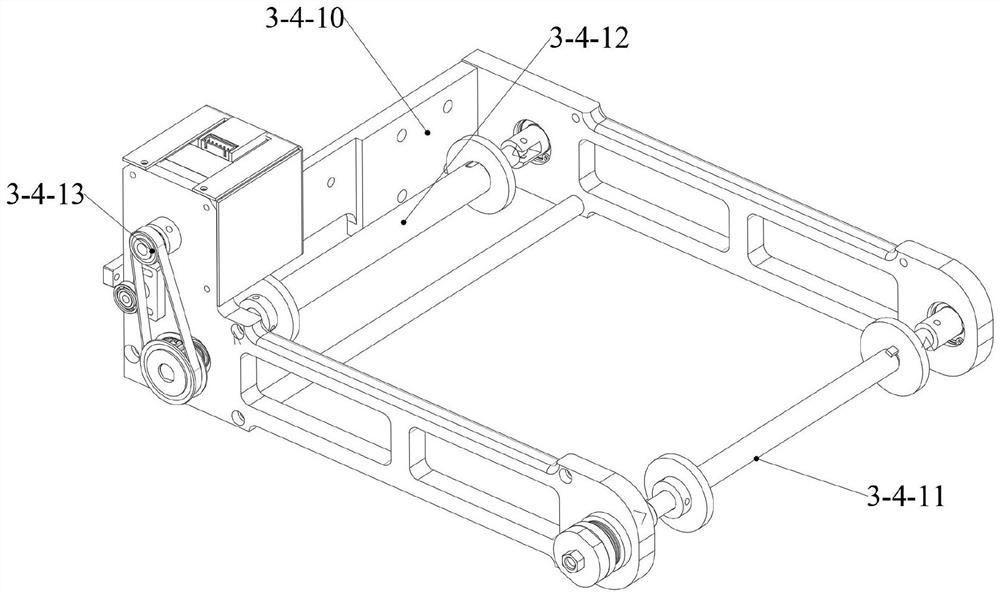

[0038] like figure 1 and 2 As shown, a cell pressure welding device includes a pressure welding base 3-1, a pressure welding horizontal adjustment assembly, a pressure welding bracket 3-2, a pressure welding lifting slide table 3-10, a lifting drive assembly, and a pressure welding support plate 3 -3 and welding mechanism 3-4. The bottom of the pressure welding bracket 3-2 and the top surface of the pressure welding base 3-1 form a sliding pair. The press-welded lateral adjustment assembly includes an adjustment seat 3-5, an adjustment screw rod 3-6 and an adjustment nut block 3-7. Two adjustment seats 3-5 are fixed on the pressure welding base 3-1. Adjusting screw rod 3-6 and two adjusting seats 3-5 constitute a revolving pair. The adjusting nut block 3-7 is fixed on the bottom of the pressure welding support 3-2, and forms a spiral pair with the adjusting screw rod 3-6. The lateral position of the adjusting seat 3-5 can be adjusted by turning the adjusting screw rod 3-6...

Embodiment 2

[0050] like Figure 4 As shown, the cell string pressure welding device is used to produce "IBC solar cell string". The structure of the IBC solar cell string is as follows figure 1 As shown, it includes six cells A and multiple ribbons B. Each battery sheet A is arranged at equal intervals in turn. Two adjacent cells A are connected by a set of ribbons B. There are four welding ribbons B in one set, and they are arranged along the direction vertical to the arrangement of battery sheets. The two ends of the four welding ribbons B respectively cover the opposite edges of the two adjacent battery sheets A. Adjacent two groups of soldering strips are staggered; therefore, any battery sheet A is connected with eight soldering ribbons B. There are four welding ribbons B covering only one battery piece on the battery piece A at the head end and the tail end respectively. During use, the welding ribbon can be placed on the designated position of the battery piece after each bat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com