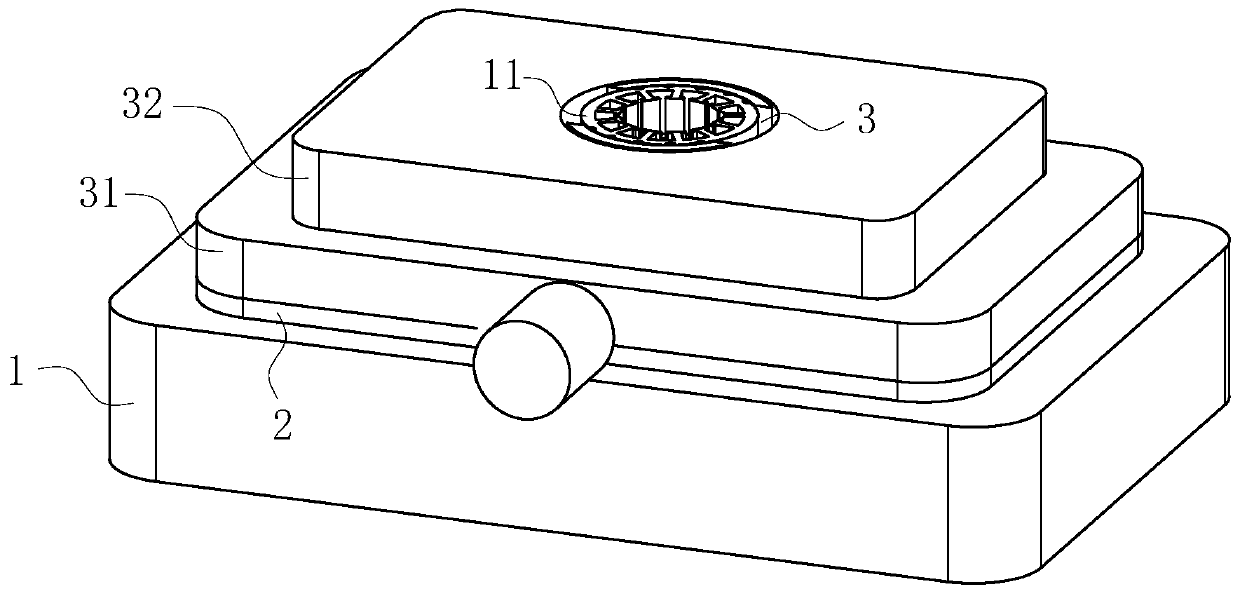

Motor iron core stamping tool

An iron core and tooling technology, applied in the field of tooling and fixtures, can solve the problems of reducing the stamping quality and stamping accuracy of the stamping workpiece, the axial rotation of the stamping workpiece, and the side lifting of the stamping workpiece. The effect of large clamping friction and reduction of rigid contact pressing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

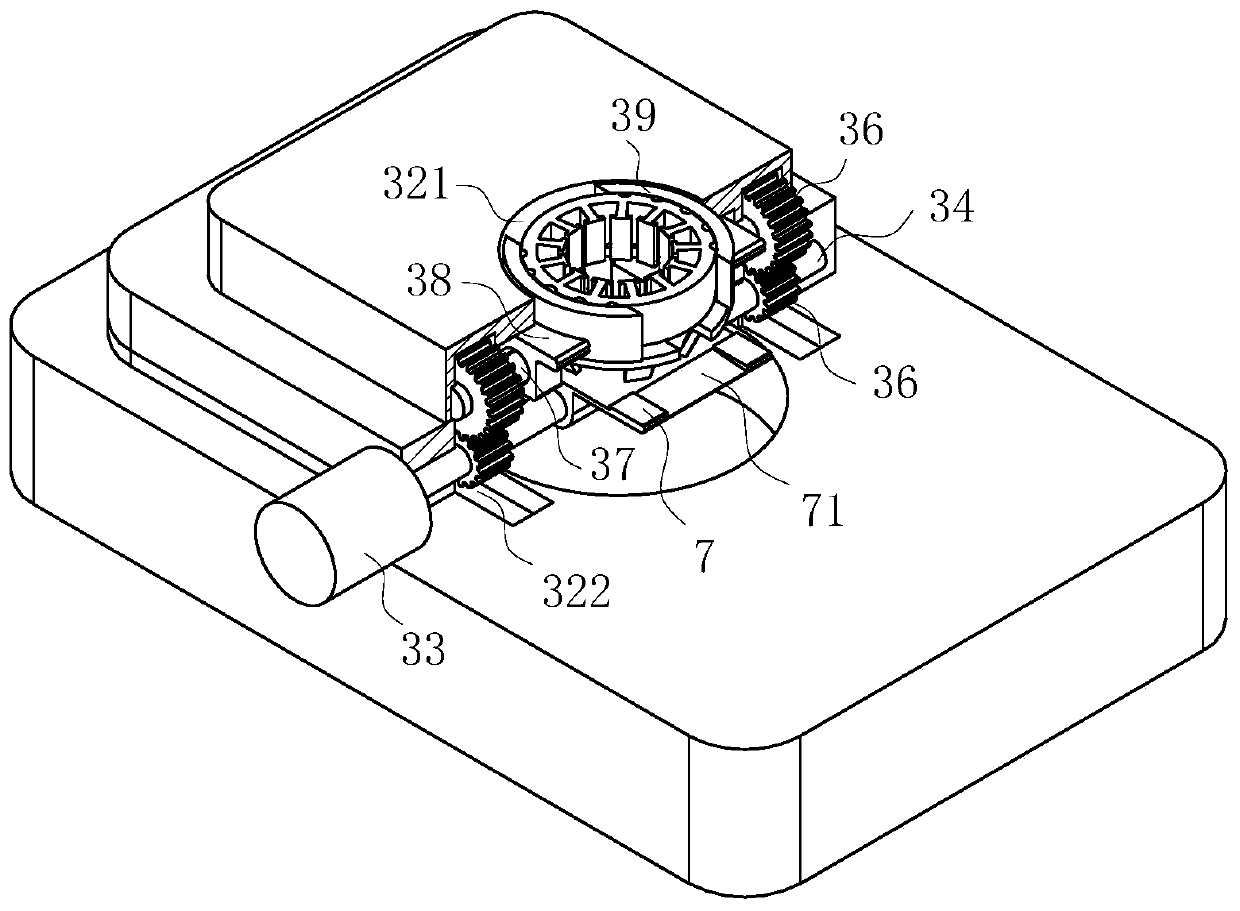

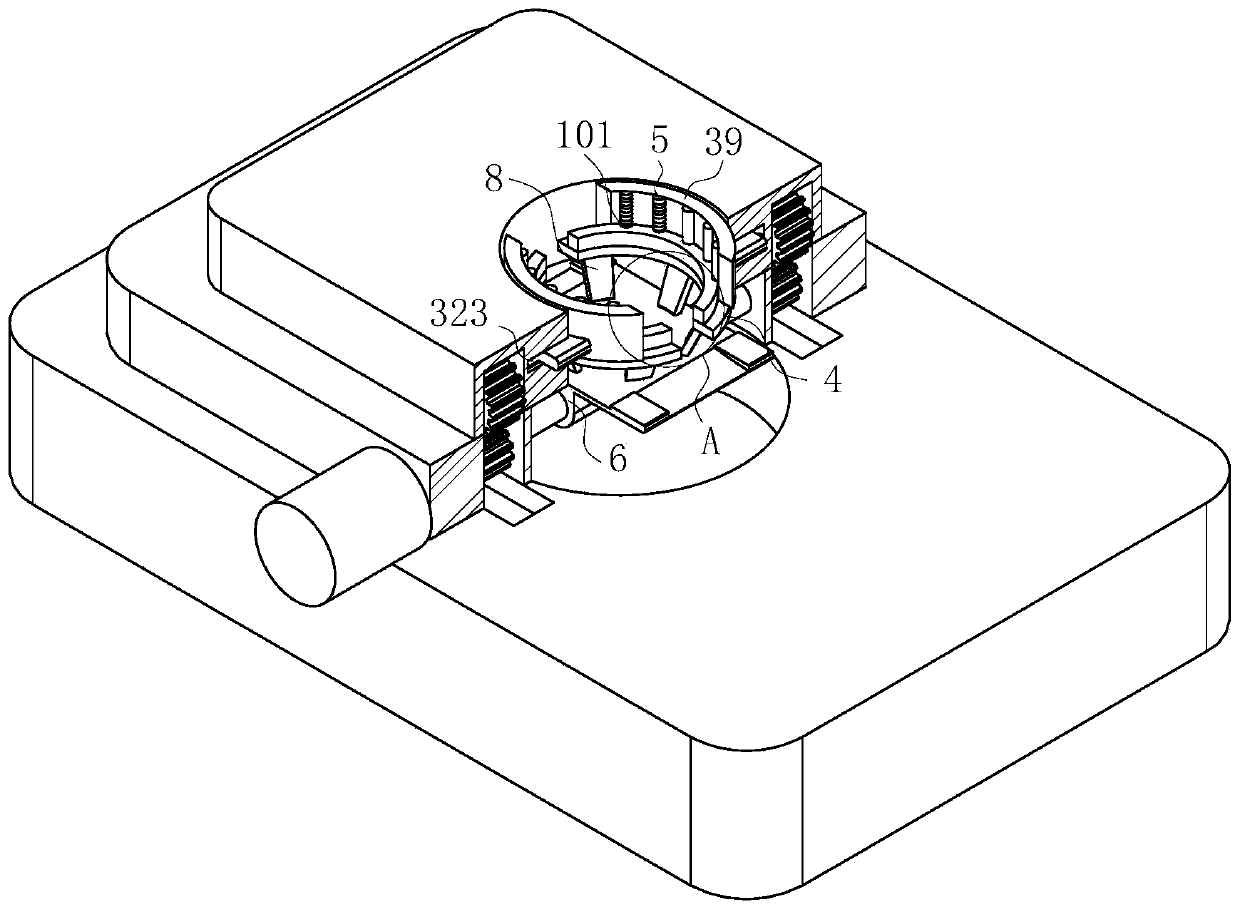

[0025] As an embodiment of the present invention, the inner wall of the curved splint 39 is vertically provided with an elastic wear-resistant strip 5, and the outer wall of the elastic wear-resistant strip 5 is provided with a corrugated layer; 11 When placed on the arc-shaped splint 39 and the arc-shaped support bar 4, the elastic wear-resistant strip 5 provided on the inner wall of the arc-shaped splint 39 is tightly attached to the outer wall of the stamping workpiece 11 under the extrusion force of the arc-shaped splint 39 Above, the elastic wear-resistant strip 5 can increase the clamping friction force between the arc splint 39 and the stamping workpiece 11, and at the same time increase the axial friction force between the stamping workpiece 11 and the arc splint 39, thereby reducing the stamping workpiece 11. The phenomenon of axial rotation deviation during stamping; at the same time, the rigid contact extrusion force between the stamping workpiece 11 and the arc spli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com