Integrated hydraulic module of an electrohydraulic servo brake

A hydraulic servo and hydraulic module technology, applied in the direction of brakes, brake transmissions, transmissions, etc., can solve the problems of insufficient durability, unreliable risk of wear and function loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

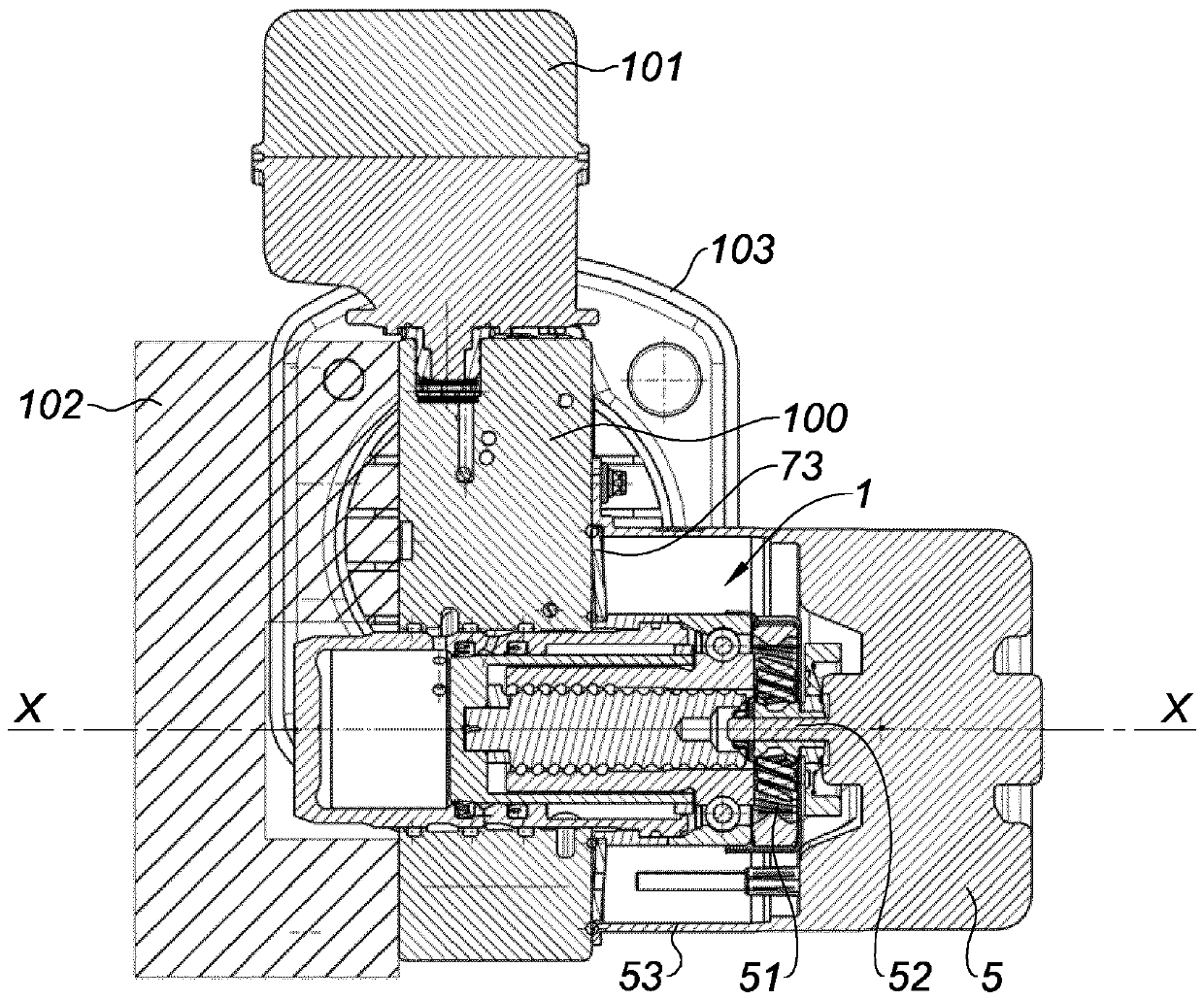

[0029] according to figure 1 The present invention has as subject a hydraulic module 1 for a hydraulic block 100 , which is covered by a brake fluid reservoir 101 which supplies the hydraulic block 100 . The control unit 102 of the module is fastened on the side of the hydraulic block 100 .

[0030] The hydraulic block 100 is traversed by a hydraulic module 1 which is externally fastened on the side of the block 1 covered by its electric motor 5 (its housing), which is itself fastened separately on the On this side of the hydraulic block 100 .

[0031] The hydraulic block 100 constructed in this way is fastened to the dash panel of the vehicle via a support plate 103 , which is carried by the rear side of the hydraulic block 100 according to the installation orientation of the block in the vehicle.

[0032] Lines traverse the hydraulic block 100 for exchanging brake fluid between the reserve device 101 and the hydraulic block 100 and between the latter and the brake circuit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com