Connector

A connector and contact piece technology, applied in the direction of connection, conductive connection, two-part connection device, etc., can solve the problems of poor stability and easy dislocation, and achieve the effects of stable contact, ensuring safety, and large flow area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

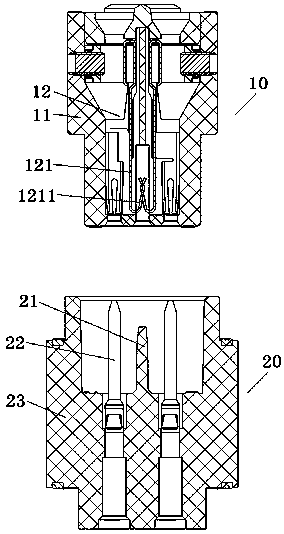

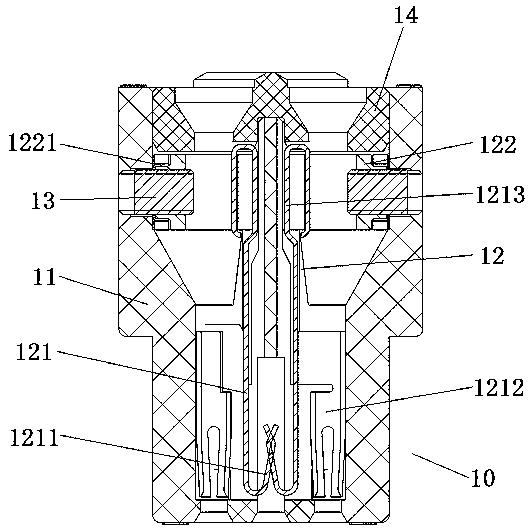

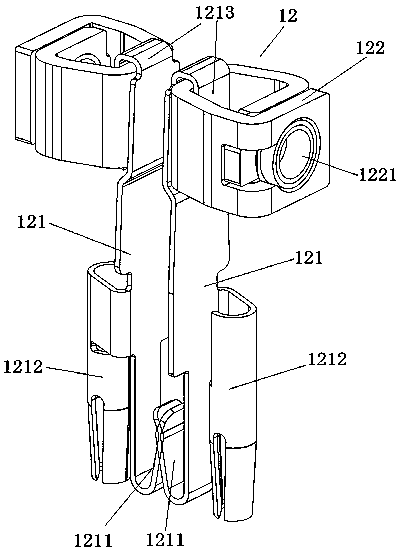

[0039] Embodiment 1 of the connector in the present invention: the connector of the present invention cooperates with the adapter connector and is used in a current transformer. The connector in the present invention is connected in the circuit of the current transformer, and the adapter connector is connected in In control equipment circuits used in conjunction with current transformers. In order to meet the technical requirement of "the current loop is not broken" when the current transformer is in use, the connector in the present invention has a self-short-circuit function (also known as an anti-open circuit function), which can The contacts in the connector are short-circuited to ensure the formation of a current loop, and the contacts in the connector are disconnected when the connector is plugged and mated with the adapter connector, so as to achieve the purpose of always keeping the current loop open.

[0040] Such as figure 1 As shown, the connector and the matching ...

Embodiment 2

[0053] Embodiment 2 of the connector of the present invention: the difference from the above embodiments is that in this embodiment, the plug-in end of the contact piece is punched with a cantilever that can be bent outward, and the cantilever is a part of the plug-in end. The cantilever cantilever is folded back to the insertion direction to form the elastic arm structure of the contact piece, and is not limited to the solution of bending the entire extension section at the lower end of the contact piece to form the elastic arm structure.

Embodiment 3

[0054] Embodiment 3 of the connector in the present invention: the difference from the above embodiments is that in this embodiment, the plug-in end of the contact piece is first turned back to the plug-in direction, and then turned perpendicular to the plug-in direction Folding to form sockets for plugging and mating with the mating contacts in the mating connector is not limited to the solution in which an epitaxial sheet is extended perpendicular to the plugging direction on the wound contact sheet body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com