Oil heater assembly of separated oil circuit and electric heater

A separate and component-based technology, which is applied in the direction of central heating components, heating methods, electric heating systems, etc., can solve the problems of many welding processes, large heat transfer constraints of oil tanks, and large waste of space, so as to save volume and space. The effect of improving core competitiveness and good experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

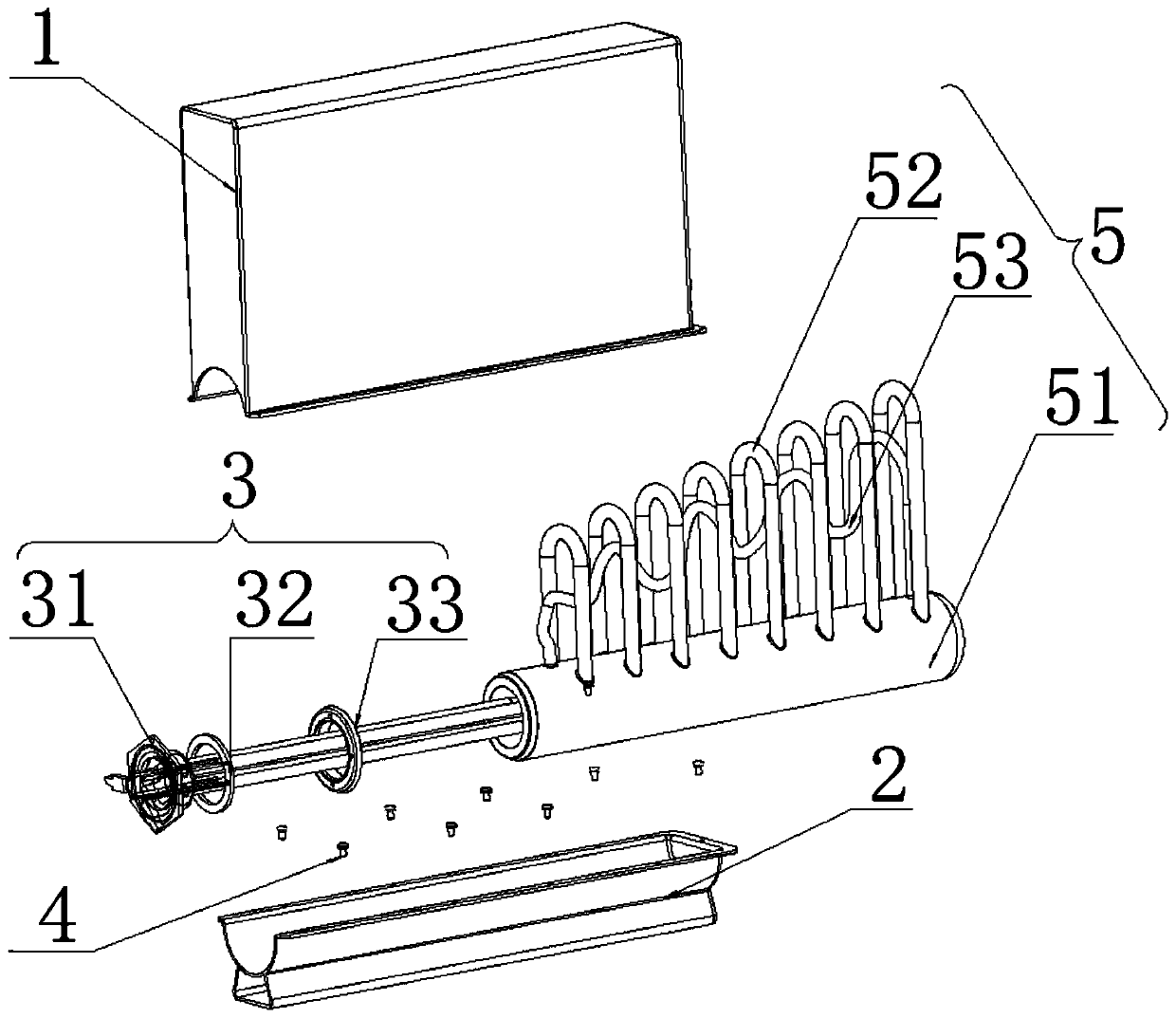

[0022] In order to better understand the purpose, structure and function of the present invention, below in conjunction with appendix Figure 1-4 , understanding of the present invention.

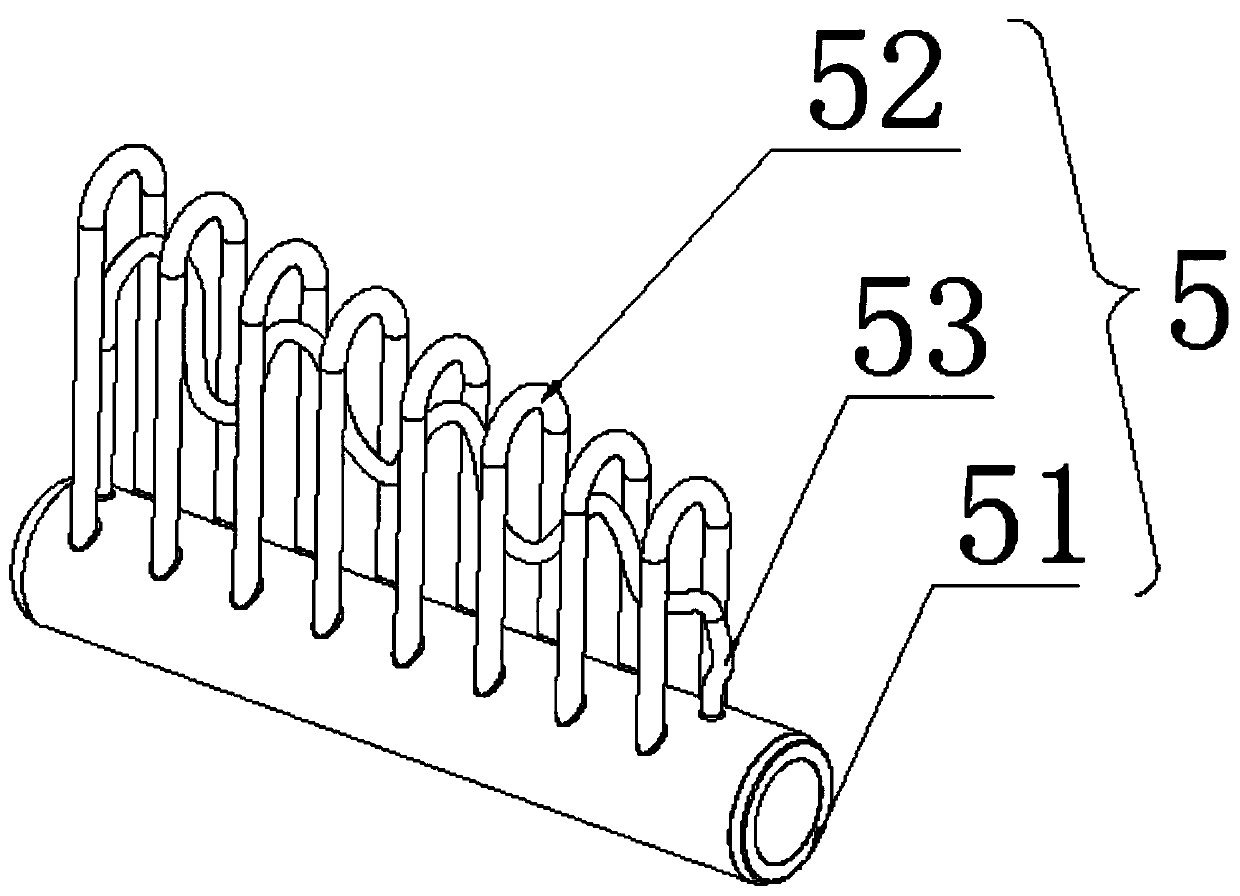

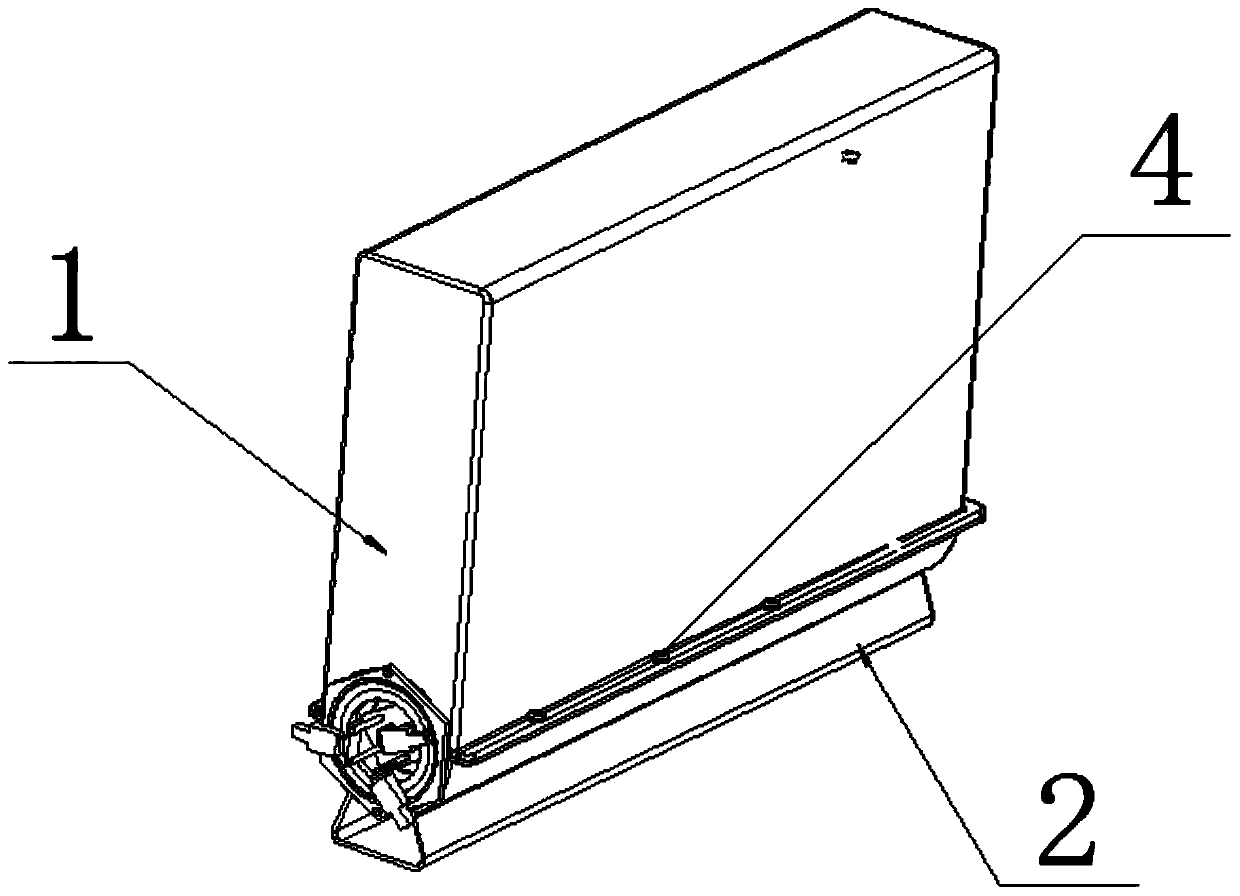

[0023] Such as figure 1 As shown, a separate oil circuit oil pump assembly is designed, including a casing, an oil storage assembly 5 arranged in the inner cavity of the casing, and a heating assembly 3 arranged in the oil storage assembly 5; wherein, the casing includes an upper cover 1 , bottom cover 2, fasteners, fasteners can choose screws 4, such as image 3 As shown, when the upper cover 1 and the bottom cover 2 are fastened to each other, the heating component 3 is stuck between the ends of the upper cover 1 and the bottom cover 2, so that the oil storage component 5 is fastened between the upper cover 1 and the bottom cover 2 In the cavity between them, screws 4 lock the upper cover 1 and the bottom cover 2 together.

[0024] The innovations of this design mainly lie in: figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com