Rust-resisting material for fluid gas phase membrane

A kind of anti-rust material and gas phase technology, which is applied in the field of fluid gas-phase film anti-rust materials, can solve the problems that the thermoplastic elastomer film can not effectively isolate the corrosive medium, the barrier performance of the film-forming material is not good, and the high air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

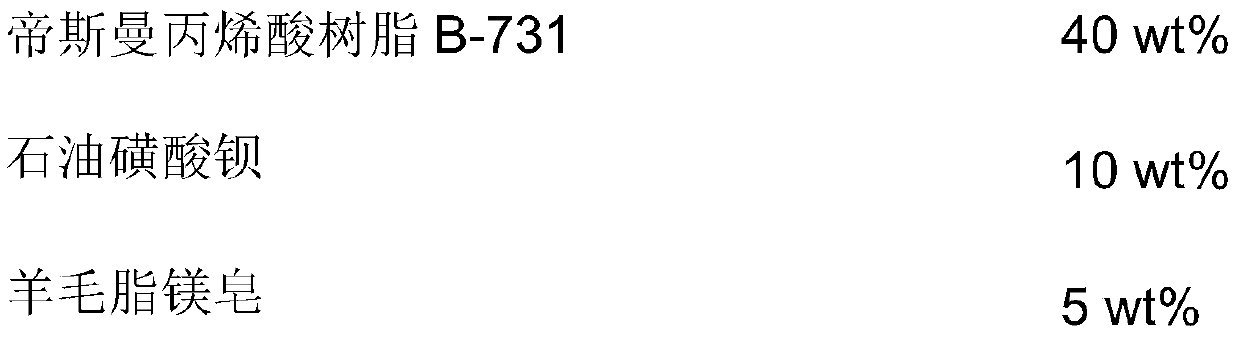

[0026] In terms of weight percentage, the fluid vapor phase film antirust material includes the following components:

[0027]

[0028]

[0029] The preparation method is as follows: (1) Add modified acrylic resin (DSM Acrylic Resin B-731) into dearomatization solvent (D40 and D110), heat to 60°C, stir until dissolved; (2) add petroleum sulfonate in sequence acid salt (barium petroleum sulfonate), lanolin derivative (magnesium lanolin soap), fatty acid salt (dicyclohexylamine octanoate), stir until dissolved; (3) cool down to 50°C, add butyl cellosolve, fat Amine (cyclohexylamine), benzotriazole derivatives, additives (sebacate), and stirred for 2 hours to obtain the fluid vapor-phase film antirust material.

Embodiment 2

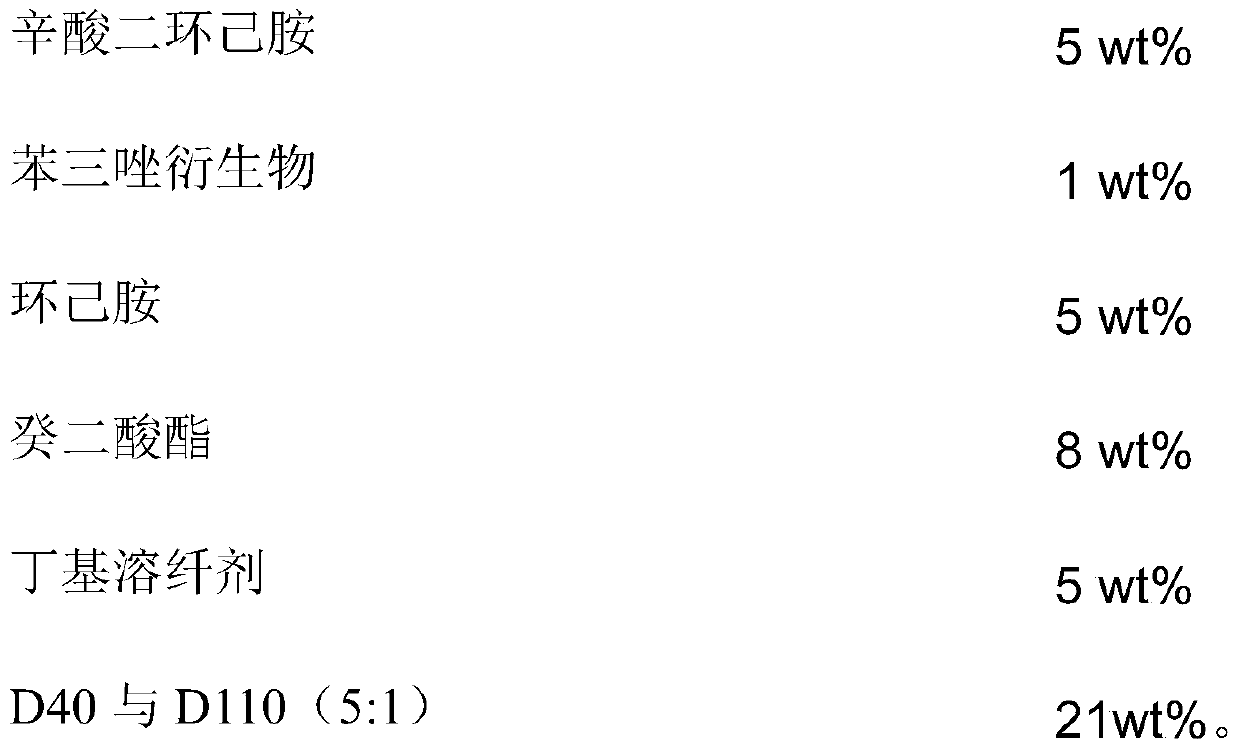

[0031] In terms of weight percentage, the fluid vapor phase film antirust material includes the following components:

[0032]

[0033]

[0034] The preparation method is as follows: (1) Add modified acrylic resin (Mitsubishi Acrylic Resin BR-116) into dearomatization solvent (D40 and D110), heat to 60°C, stir until dissolved; (2) add petroleum sulfonate in sequence (barium dinonylnaphthalene sulfonate), lanolin derivative (lanolin pentaerythritol ester), fatty acid salt (dicyclohexyl octoate), stir until dissolved; (3) cool down to 50°C, add butyl cellosolve, Organic acid (capric acid), benzotriazole derivatives, additives (oxidized soybean oil), and stirred for 2 hours to obtain the fluid vapor phase film antirust material.

Embodiment 3

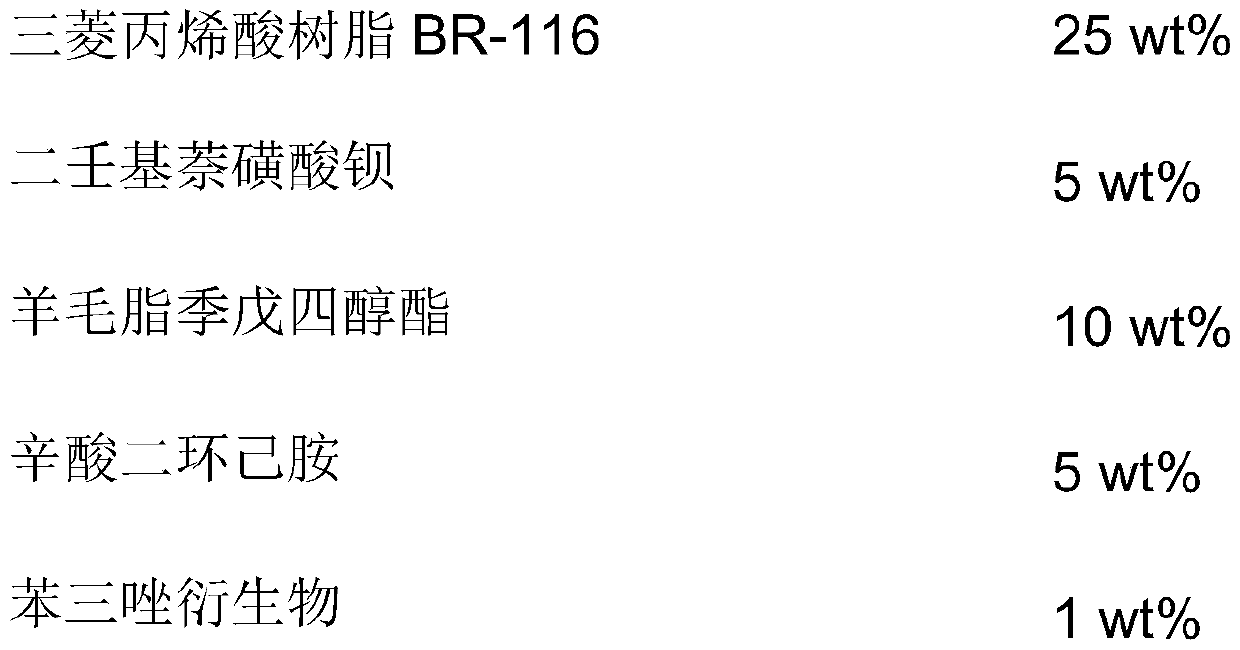

[0036] In terms of weight percentage, the fluid vapor phase film antirust material includes the following components:

[0037]

[0038]

[0039] The preparation method is as follows: (1) Add modified acrylic resin (Rohm and Haas acrylic resin PARALOID B-67) into dearomatization solvent (D40 and D110), heat to 60°C, stir until dissolved; (2) Add in sequence Petroleum sulfonate (calcium dinonylnaphthalene sulfonate), lanolin derivative (magnesium lanolin soap), fatty acid salt (dicyclohexylamine octanoate), stir until dissolved; (3) Cool down to 50°C, add in sequence Butyl cellosolve, aliphatic amine (cyclohexylamine), benzotriazole derivatives, additives (citrate), and stirring for 2 hours to obtain the fluid vapor-phase film antirust material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com