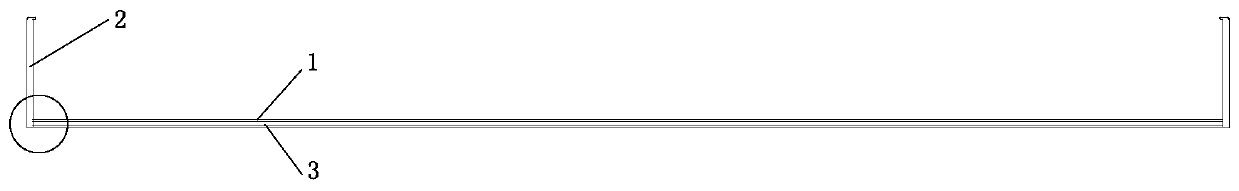

Mobile phone protective sleeve and production process thereof

A mobile phone protective cover and protective cover technology, applied in the direction of layered products, telephone structure, synthetic resin layered products, etc., can solve the problems of uneven quality, loss, poor decoration effect, etc., and achieve performance standard improvement, anti-corrosion The effect of improved anti-seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

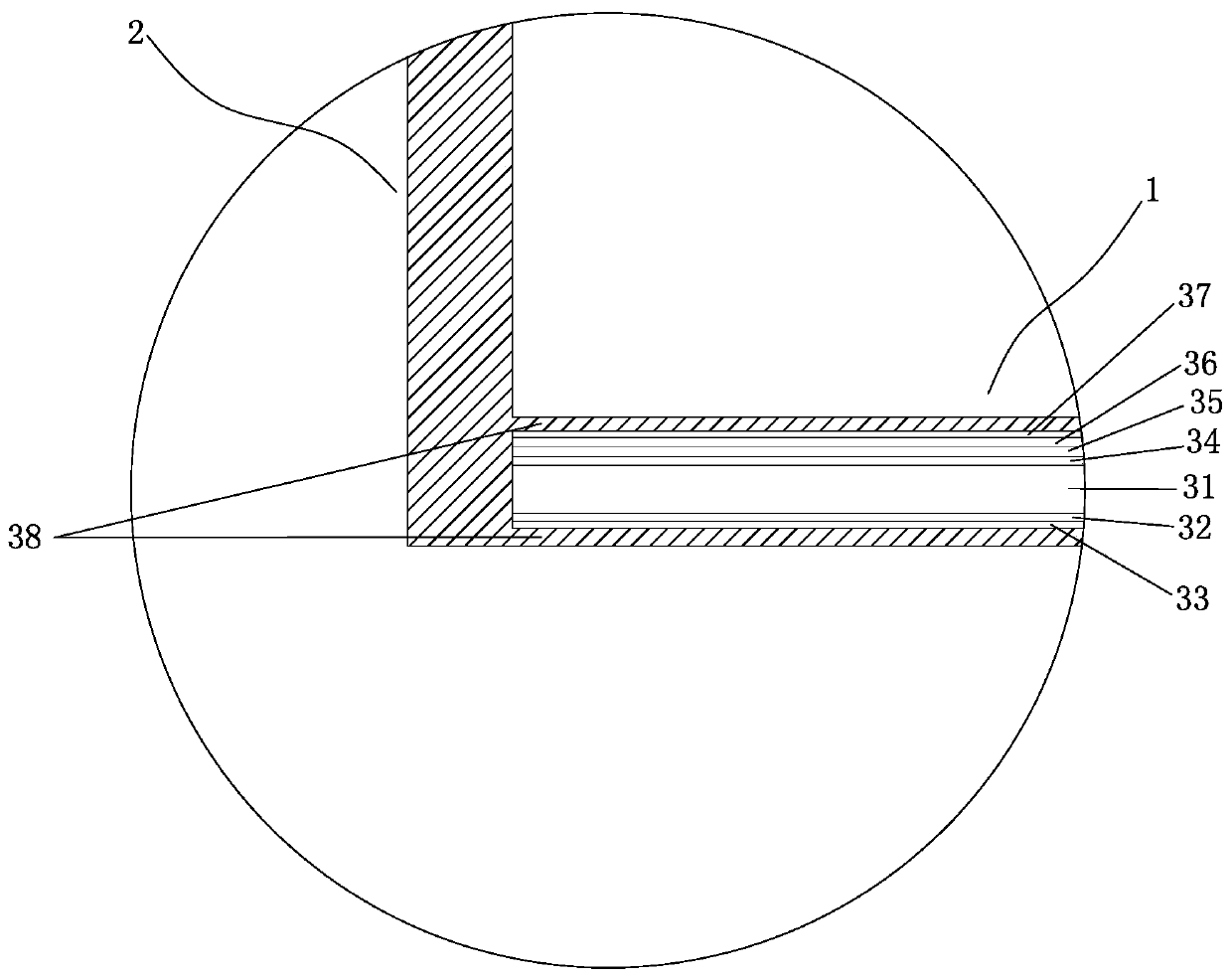

[0048] 1. Production process: PMMA / PC composite board → printing metal ink and color transparent ink and color masking ink → use C 2 Process transfer resin to produce laser holographic image texture layer → perform two kinds of optical coatings with different reflectivity → perform printing and coating of various functions according to process requirements → coat heat-resistant and high-temperature functional primer layer → high-pressure molding and fine carving → Perform UV resin coating to form a surface hardened layer → Apply an adhesion-promoting functional coating on the surface (upper surface) of the UV cured resin layer → Perform IMD processing. Specifically include the following steps:

[0049] Step 1: Print transparent ink and masking colored ink on the inner surface of the PMMA / PC composite board;

[0050] Step 2: Using C 2 The process transfer resin produces a laser holographic image texture layer, the thickness of the image resin is 2.5--3.0 μm, and the depth of ...

specific Embodiment 2

[0063] 1. Production process: PMMA / PC composite board → printing pearlescent ink, transparent color printing ink and masking ink → using water transfer printing process to transfer resin to produce laser holographic image texture layer → transparent brightening optical coating → execute according to process requirements All kinds of printing and coating→coating heat-resistant and high-temperature-resistant functional base coat→high-pressure molding and fine carving→executing UV resin coating to form a surface hardening layer→coating the surface (upper surface) of the UV hardening resin layer with an adhesion-promoting functional coating Layer → Perform IMD machining. Specifically include the following steps:

[0064] Step 1. Print pearlescent ink, transparent color ink, and masking ink on the inner surface of the PMMA / PC composite board.

[0065] Step 2, using a water transfer printing process to transfer the resin to produce a laser holographic image texture layer, the thick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com