A Measuring Device for Machine Tool Geometric Error Based on the Principle of Laser Interferometry

A technology of laser interference and geometric error, applied in mechanical measuring devices, measuring devices, using mechanical devices, etc., can solve the problems of high measurement cost, time-consuming, laborious, and expensive, and achieve flexible device movement, simple operation, and high satisfaction. The effect of precision measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

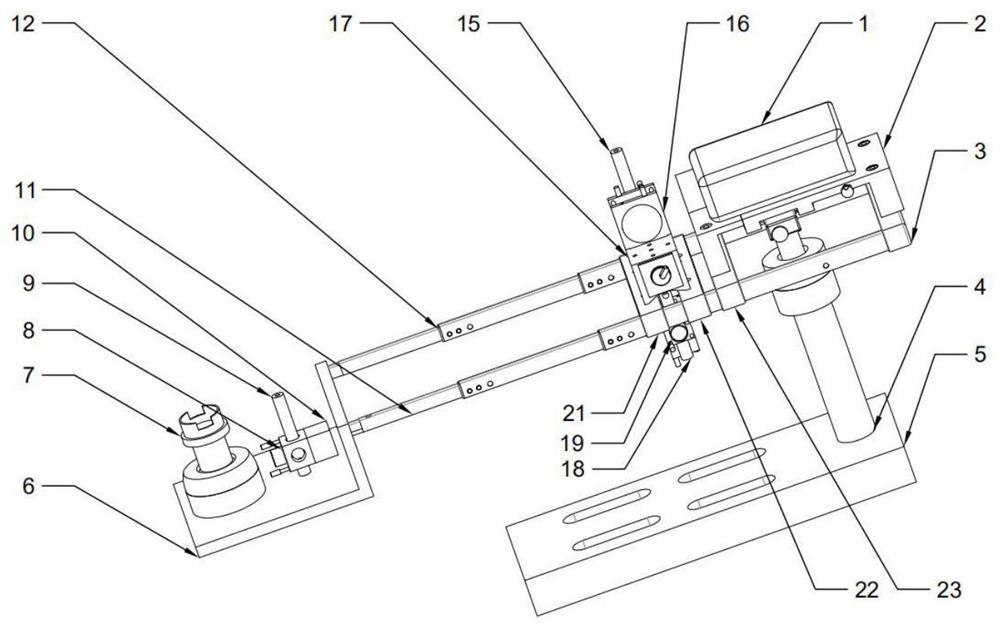

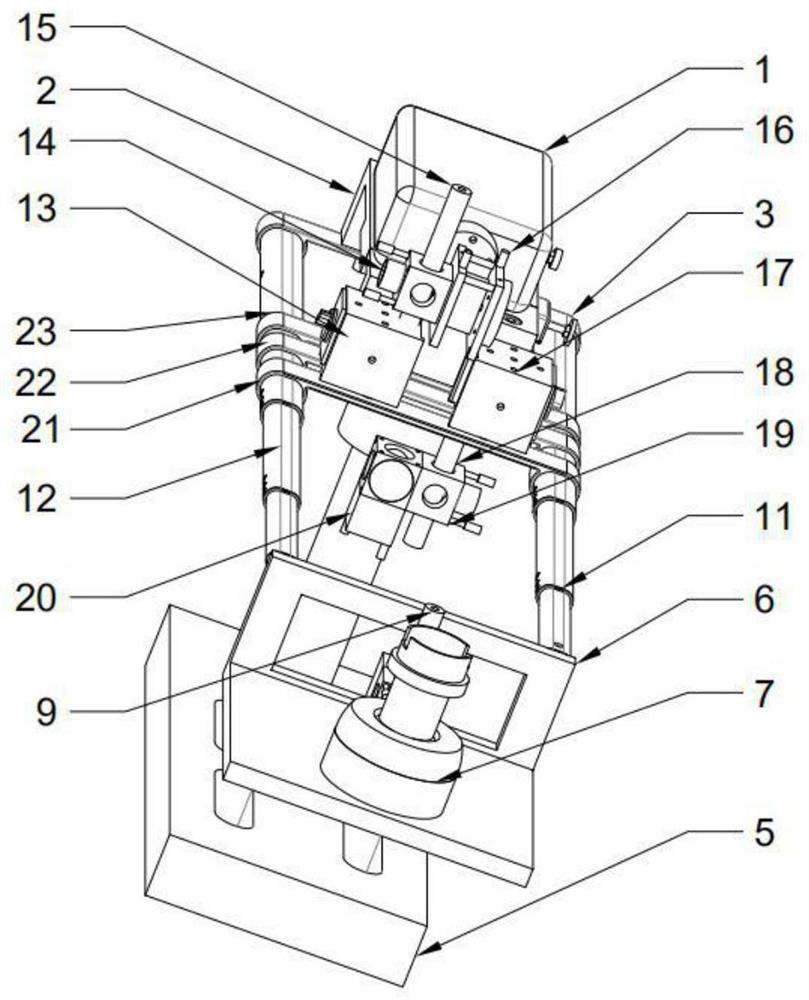

[0032] refer to figure 1 , figure 2 , a machine tool geometric error measuring device based on the principle of laser interference, including a mechanical tracking device and a laser measuring device installed on it;

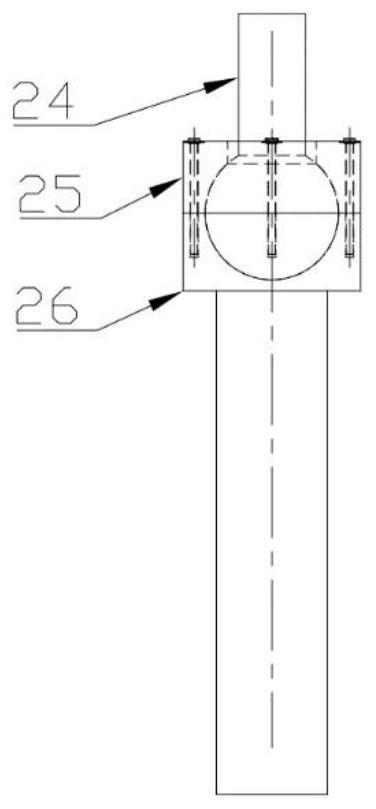

[0033] The mechanical tracking device includes a laser interferometer 1, the laser interferometer 1 is fixed on the interferometer adjustment platform 2 through threaded connection, the bottom of the interferometer adjustment platform 2 is connected with the work billiard ball hinge 4, and the bottom of the work billiard ball hinge 4 Installed on the machine tool connection platform 5; the interferometer adjustment platform 2 is fixed on the upper mounting base 3 and the lower mounting base 3 23, and the upper mounting base 3 and the lower mounting base 23 are inserted into the first telescopic rod 11 and the second telescopic rod 12, and use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com