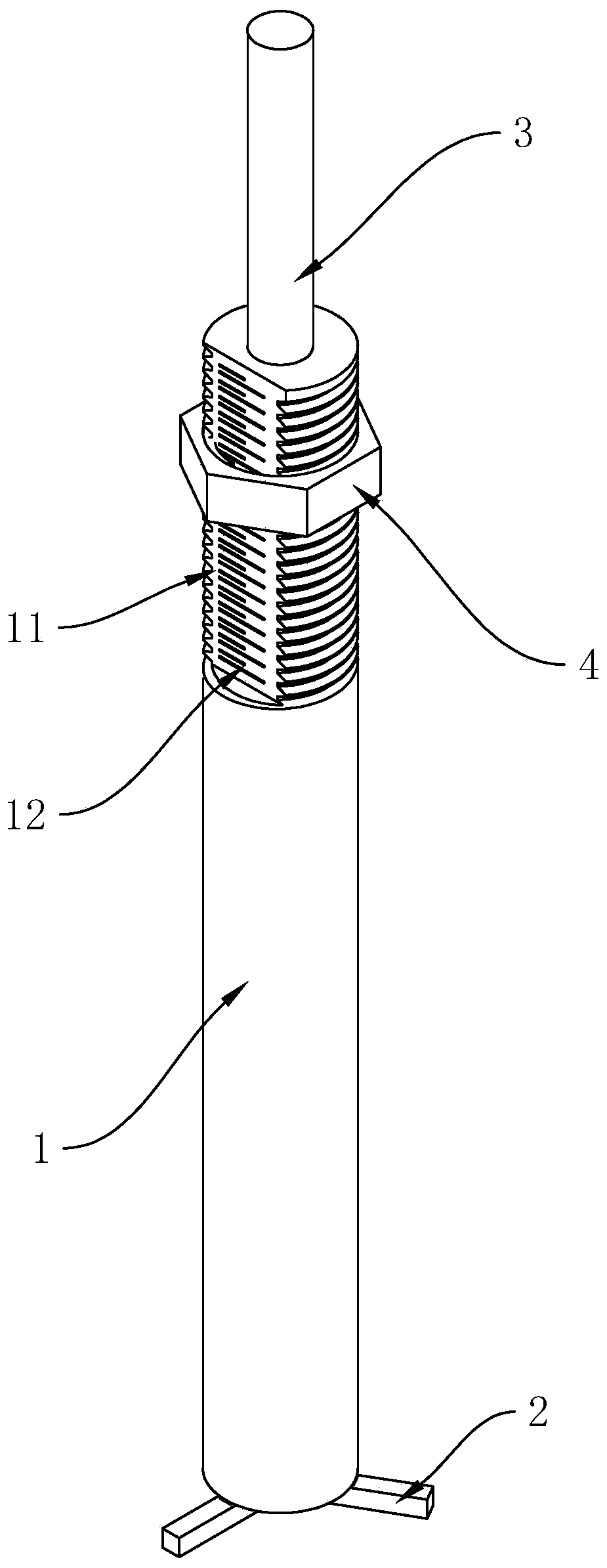

Floor thickness measuring device

A technology of thickness measurement and floor slab, applied in the direction of mechanical thickness measurement, etc., can solve the problems of high labor cost, low cost, high cost, etc., and achieve the effect of simple structure, easy use, and reduced labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

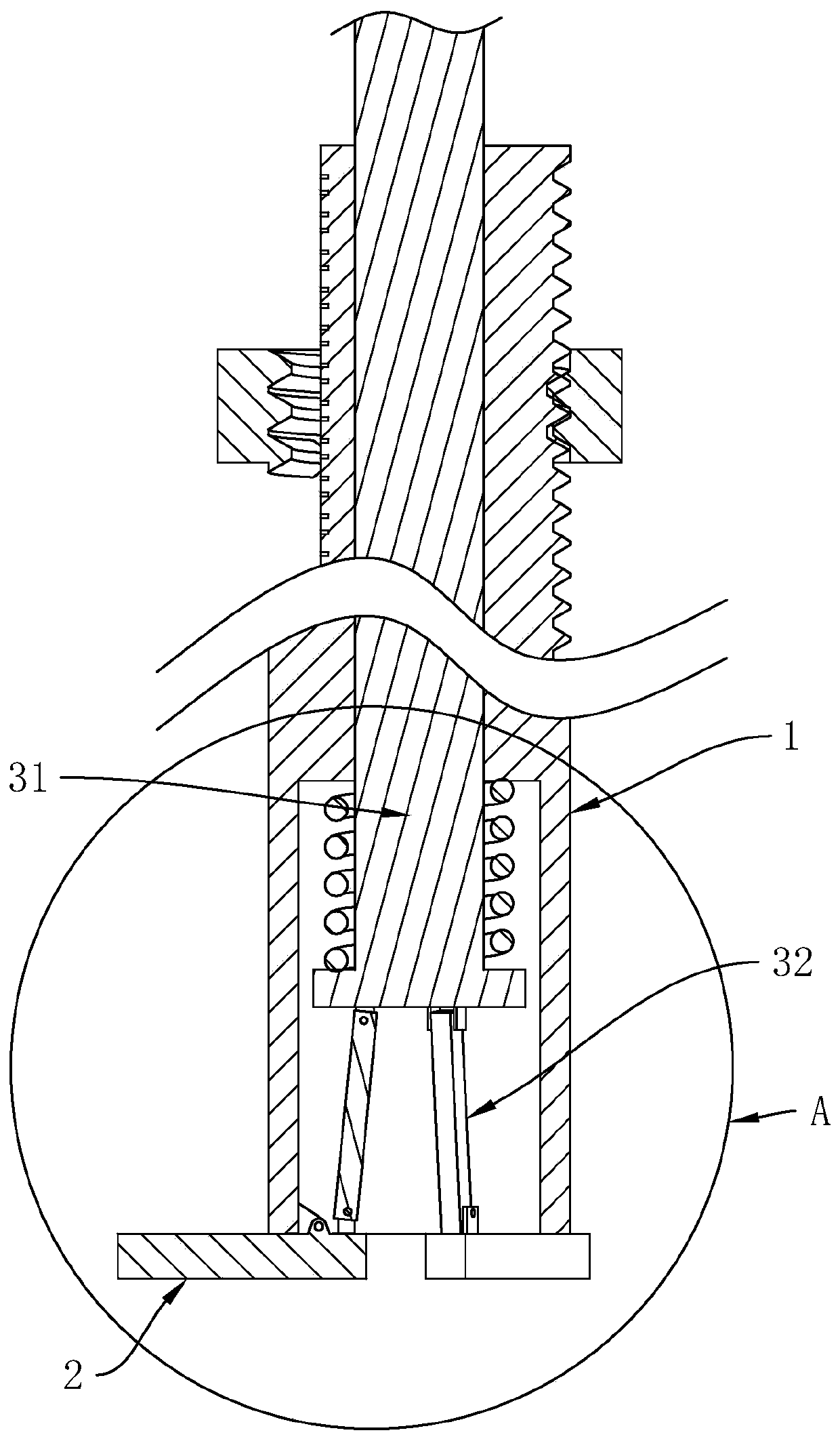

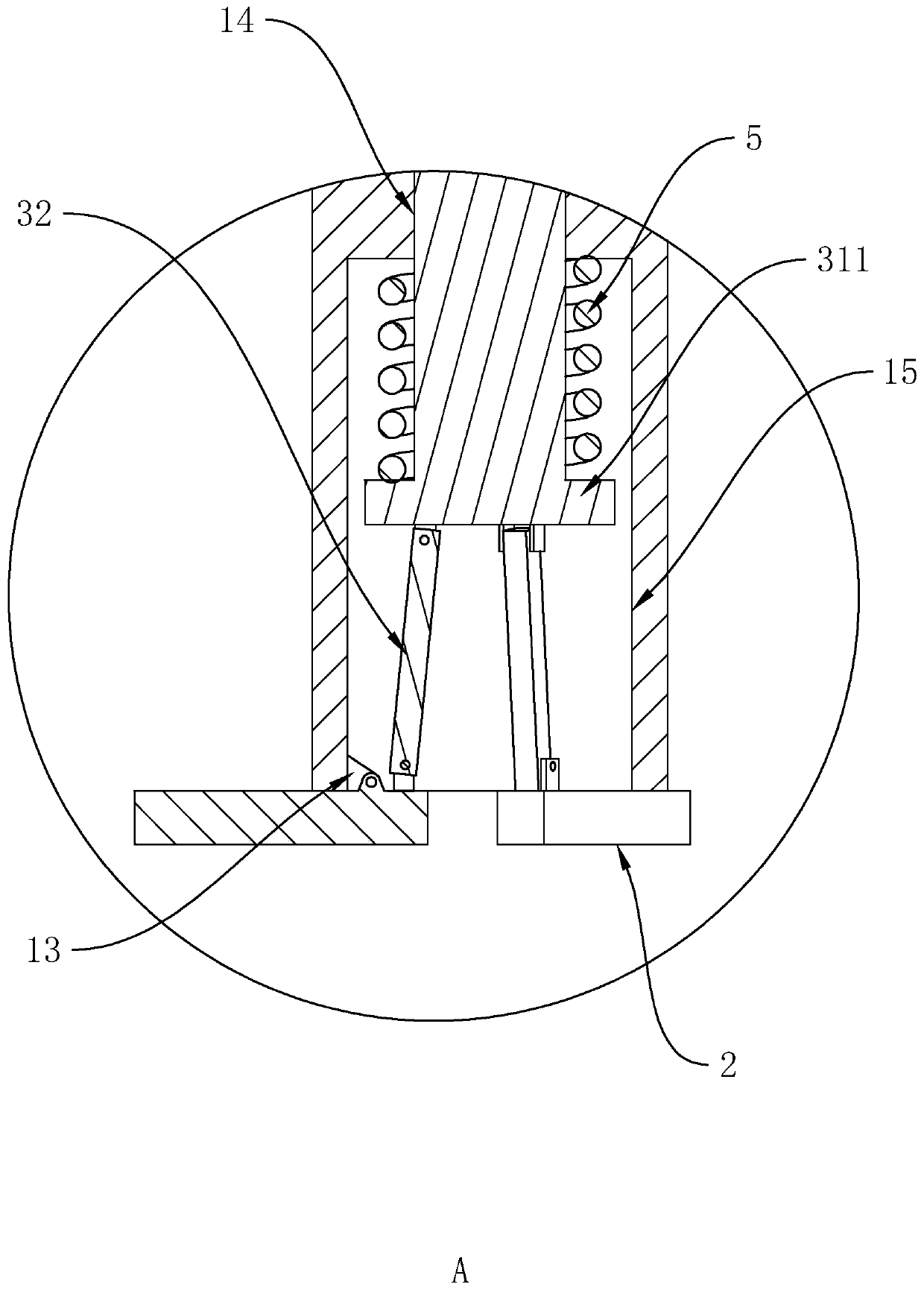

[0044] to combine Figure 4 and Figure 5 As shown, the difference from Embodiment 1 is that in Embodiment 2, the outer cylinder rod 1 is provided with an opening at one end of the limit card 2, and the driving mechanism 3 includes a Out of the outer cylinder rod 1 to drive each piece of limit card 2 toward the direction away from the axis of the outer cylinder rod 1 The driving rod 31 and several pieces are sleeved on each piece of limit card 2 and extend into the outer cylinder rod 1 One end is used to drive the first spring 22 that is used to drive each piece of the limit card 2 towards the direction close to the axis of the outer cylinder rod 1; wherein, combined with Figure 6 As shown, a plurality of slots 16 are arranged on the outer wall of the lower end of the outer cylinder rod 1, and each limit card 2 is inserted into each slot 16 respectively, and each limit card 2 is close to one end of the axis of the outer cylinder rod 1 The outer wall of the ring limit card 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com