Tripod telescopic rod

A telescopic rod and tripod technology, which is applied in the direction of rod connection, connecting components, mechanical equipment, etc., can solve the problems of complicated operation, difficult to control cost, inconvenient users, etc., and achieve the effect of improving effect, convenient operation and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

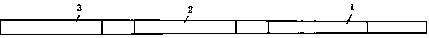

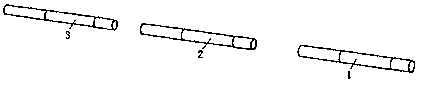

[0021] see Figure 1-3 , a tripod telescopic rod, including a first tube 1, a second tube 2 and a triode 3, one end of the first tube 1 close to the diode 2 runs through the diode 2 and extends to the inside of the diode 2 and is movably connected to the inside of the diode 2, and the diode 2 One end close to the triode 3 runs through the triode 3 and extends to the inside of the triode 3 to be flexibly connected with the inner wall of the triode 3. The primary tube 1, the diode 2 and the triode 3 are all made of carbon fiber or glass fiber. The primary tube 1 and the diode 2 and the cross-sectional shape of the triode 3 can be designed in various ways. The cross-sectional shapes of the first-stage tube 1, diode 2 and triode 3 are designed to be ellipse, a circle with a plane, and a circle with anti-rotation grooves or convex lines to avoid the relative contact between the two tubes. Turn, the left and right sides of the primary tube 1, diode 2 and triode 3 are equally divided...

Embodiment 2

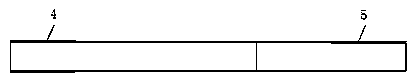

[0023] see Figure 4-5 , a tripod telescopic rod, including a first tube 1, a second tube 2 and a triode 3, one end of the first tube 1 close to the diode 2 runs through the diode 2 and extends to the inside of the diode 2 and is movably connected to the inside of the diode 2, and the diode 2 One end close to the triode 3 runs through the triode 3 and extends to the inside of the triode 3 to be flexibly connected with the inner wall of the triode 3. A gap 6 is provided on one side of the primary tube 1, the diode 2 and the triode 3. The primary tube 1 and the diode 2 Mounting holes 7 are provided on both sides of the notch 6 of the triode 3, an elastic member 8 is provided on the opposite side of the primary tube 1, diode 2 and triode 3, and a convex hull 9 is provided on the elastic member 8, and the convex hull 9 is connected to the triode 3. The assembly hole 7 is matched, and the elastic part 8 can be made of metal elastic material, rubber elastic material, or plastic elas...

Embodiment 3

[0025] see Figure 6-7 , a tripod telescopic rod, including a first tube 1, a second tube 2 and a triode 3, one end of the first tube 1 close to the diode 2 runs through the diode 2 and extends to the inside of the diode 2 and is movably connected to the inside of the diode 2, and the diode 2 One end close to the triode 3 runs through the triode 3 and extends to the inside of the triode 3 to be flexibly connected with the inner wall of the triode 3. A gap 6 is provided on one side of the primary tube 1, the diode 2 and the triode 3. The primary tube 1 and the diode 2 Mounting holes 7 are provided on both sides of the notch 6 of the triode 3, an elastic member 8 is provided on the opposite side of the primary tube 1, diode 2 and triode 3, and a convex hull 9 is provided on the elastic member 8, and the convex hull 9 is connected to the triode 3. The assembly hole 7 is matched, and the elastic member 8 is equipped with a locking protrusion 10. When the pipe is pulled to the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com