Ceramic tile cement pointing device for construction site

A technology for construction sites and ceramic tiles, which is applied in construction, building construction, etc., can solve problems such as low compaction efficiency, achieve the effects of saving cement materials, preventing cement overflow, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

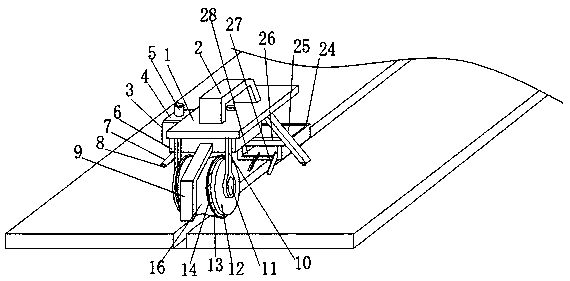

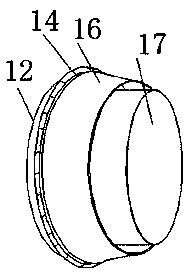

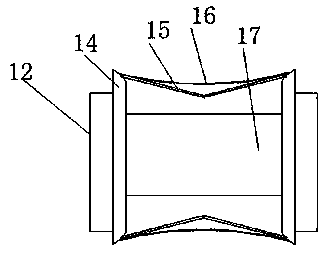

[0031] refer to Figure 1-6 , a tile cement pointing device for a construction site, comprising a fixed plate 1, a support rod 10 is welded on both sides of the bottom end of the fixed plate 1, and a rotating column 11 is connected to the bottom end of the support rod 10 through a rotating shaft. One end of the rotating column 11 is welded with a rotating block 12, the outer portion of the rotating block 12 is welded with a limiting ring 13, the outer portion of the limiting ring 13 is welded with a rubber ring 18, and the outer portion of the rubber ring 18 is welded with an arc-shaped rubber layer 14, Several bending rods 15 are welded between the two arc-shaped rubber layers 14, and the middle part of the bending rods 15 is provided with a torsion spring, and a connecting column 17 is welded between the two rotating blocks 12. There is a soft rubber layer 16. When the pressing device is used to joint the tile gap, the white cement will fall into the gap. At the same time, t...

Embodiment 2

[0040] refer to Figure 7 , a ceramic tile cement pointing device for a construction site. Compared with Embodiment 1, in this embodiment, in order to improve the stability of the power plate when the device is stirring, a rectangular strip 31 is welded on the inner wall of the top of the mixing chamber 3, and the mixing chamber 3 The inner wall is welded with a rubber clip 33 above the rectangular strip 31. The inside of the rubber clip 33 is provided with an arc-shaped slot 32. The outside of the power board 4 is provided with a rubber clip 34, and one side of the rubber clip 34 is There is an arc surface 35. When the motor 5 is turned on, due to the vibration of the motor 5 itself, the power plate 4 constantly vibrates at the top of the mixing chamber 3, and the rubber block 34 is engaged with the rubber clip 33, which improves the power plate 4 and the rubber clamping strip 33. The engagement ability of the stirring chamber 30 prevents the power plate 4 from being separate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com