Triangular welding strip production system, tin coating device thereof, air knife system of tin coating device and air knife of air knife system

A technology of air knife and tin surface, applied in the direction of coating, metal material coating process, furnace type, etc., can solve the problems of poor tin coating effect on segmented triangular solder strips, affecting the quality of solder strips, etc., to avoid tin liquid The effect of splashing and tin layer uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with the accompanying drawings.

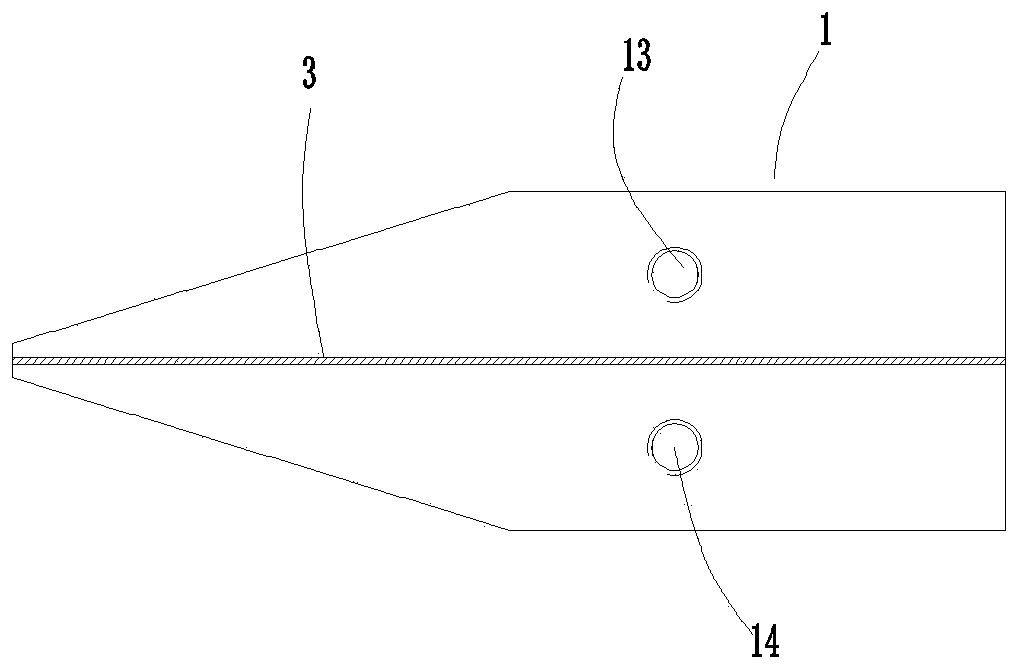

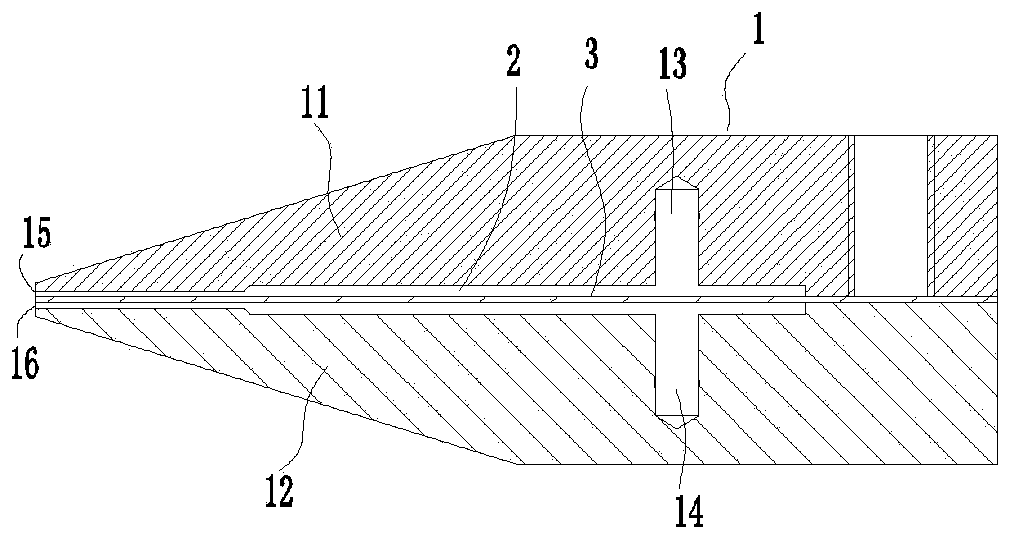

[0052] like figure 1 and figure 2 As shown, a kind of air knife of the present invention comprises a body 1, and two independent air cavities 2 are symmetrically arranged inside the body, and are separated by an air knife spacer 3 between the air cavities 2; The air knife air inlet connected to the air chamber 2 is used to connect the air source; the body 1 is provided with an air knife air outlet connected to each air chamber 2 . Specifically, the body 1 includes an upper air knife block 11 and a lower air knife block 12, and the air knife air inlet includes an upper air knife air inlet 13 arranged on the upper air knife block 11, and an air knife air inlet 13 arranged on the lower air knife block. The air knife inlet 14 of the lower floor; Between the air knife air outlet 16 of the lower floor. The air knife air outlets of the two air chambers 2 are adjacent to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com