Movable arm type tower crane underframe ballasting foundation and construction method

A tower crane and underframe technology, applied in the direction of cranes, etc., can solve the problems of large manpower, material resources, long construction period, troublesome dismantling of the tower crane foundation, etc., and achieve the effect of reducing construction waste, ensuring waterproof effect, and convenient and fast splicing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

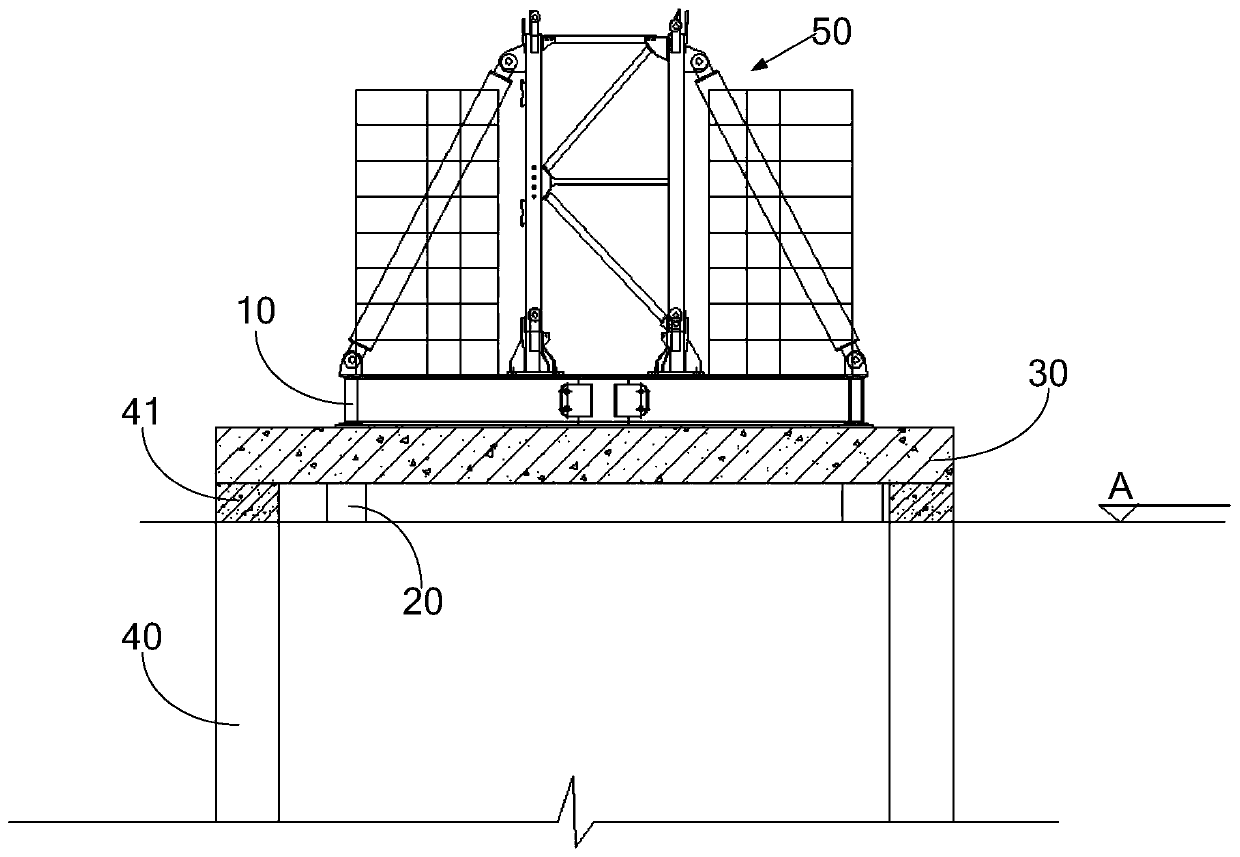

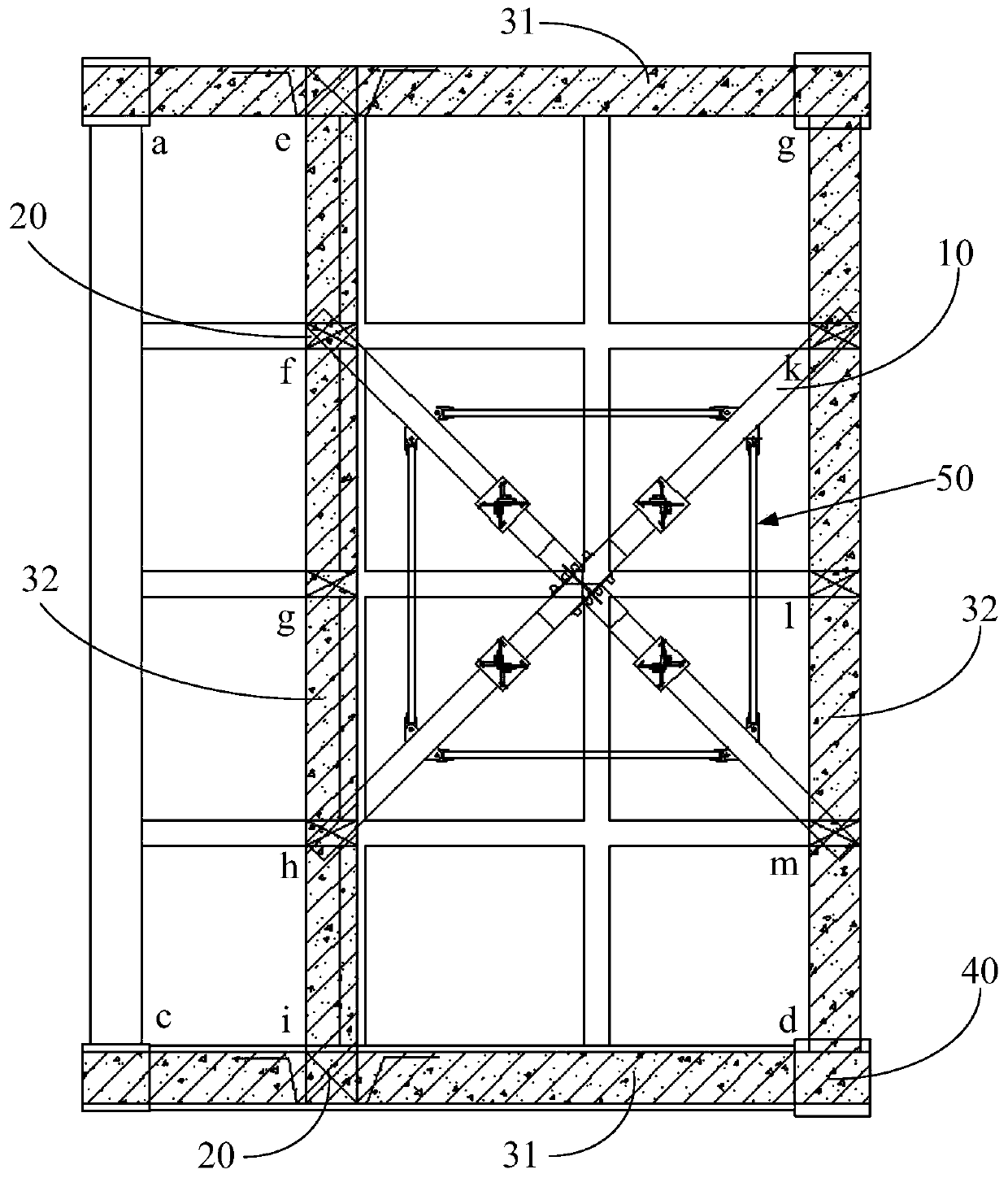

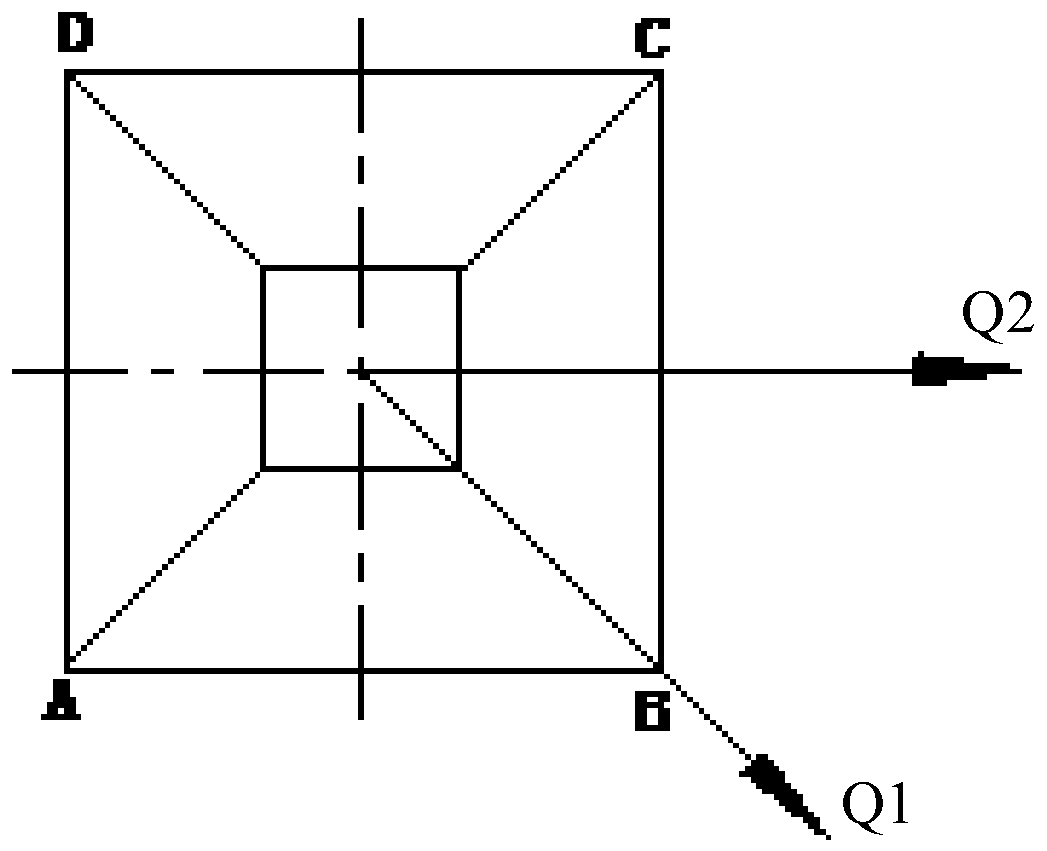

[0029] The traditional tower crane foundation is a simple cuboid concrete foundation, and the tower crane is fixed on the concrete foundation. However, this kind of tower crane foundation is large in size and requires more concrete and steel bars to make. , It is often necessary to excavate and drill holes to bury steel lattice columns. After the construction is completed, it is very troublesome to dismantle the tower crane foundation, which requires a lot of manpower and material resources, and produces a lot of construction waste, which pollutes the environment. The present invention develops a movable arm type tower crane underframe weight type foundation, which is placed on the basement, and the basement structure is used to fix and support the tower crane support. At the same time, the traditional concrete cap is replaced by a reinforced concrete beam. Under the premise of reducing the bearing capacity of the tower crane foundation, raw materials such as concrete and stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com