Tobacco product cigarette holder cooling performance testing device and method

A technology for tobacco products and testing devices, which is applied in the direction of thermal development of tobacco and materials, can solve the problem that it cannot be used to measure the cooling performance of cigarette holders, and achieves the effects of simple structure, convenient operation and accurate measurement results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

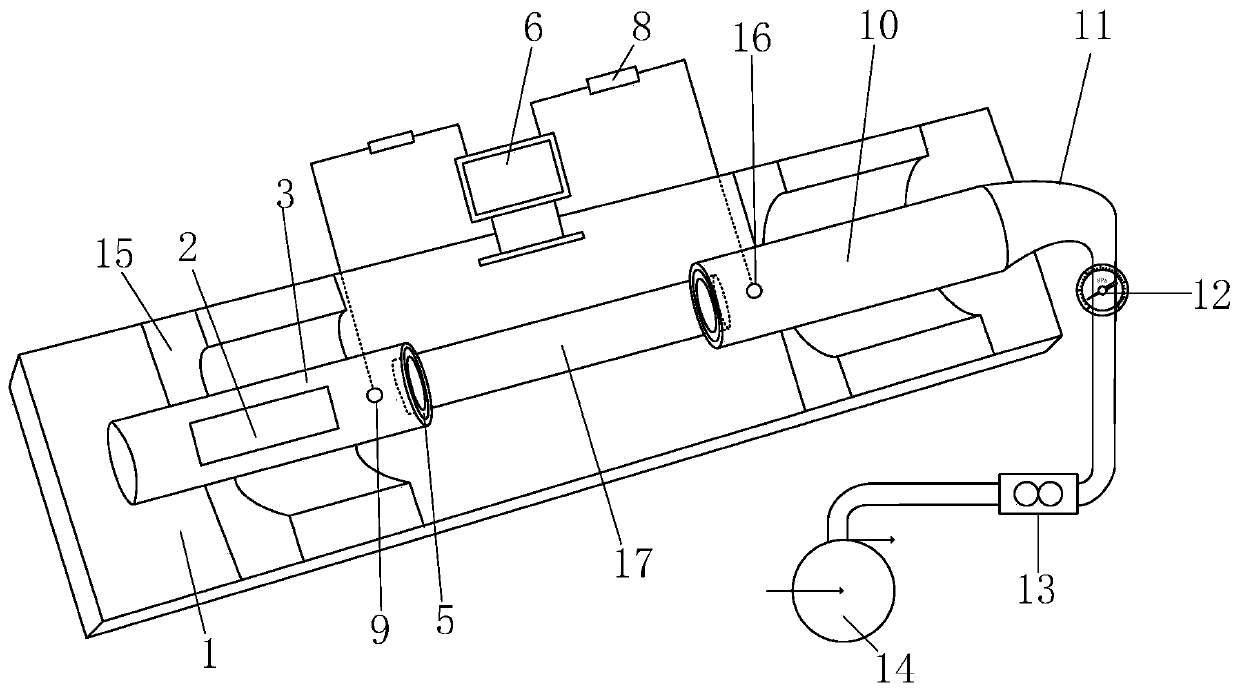

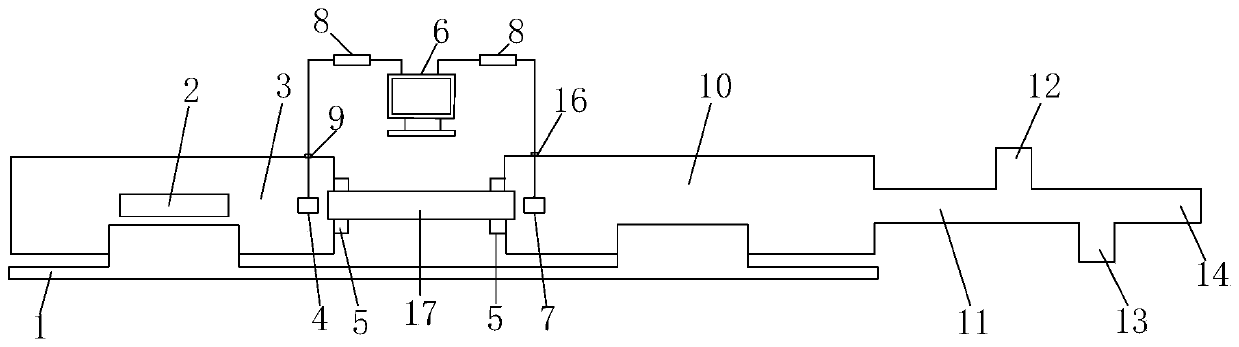

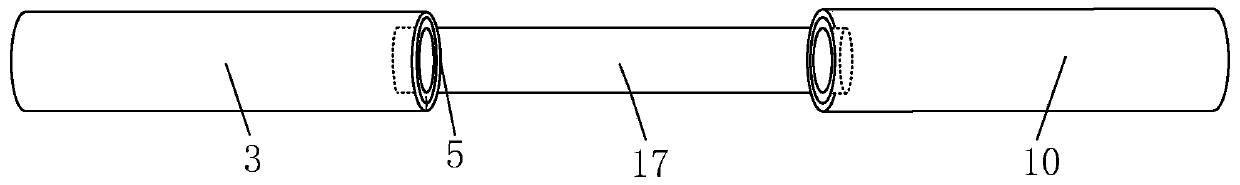

[0040] (1) The cigarette holder 17 is cut to a length of 2.5cm; the two ends of the cigarette holder 17 are respectively inserted into the pipe mouth of the cigarette holder of the air inlet pipe 3 and the outlet pipe 10, until the distance between the first temperature sensor 4 and the second temperature sensor 7 is respectively At 1 mm of the temperature measuring element, the distance between the temperature measuring element of the first temperature sensor 4 and the mouthpiece clamping end of the intake pipe 3 and the distance between the temperature measuring element of the second temperature sensor 7 and the mouthpiece clamping end of the air outlet pipe 10 The distance is 2mm, and the gap between the cigarette holder 17 and the nozzle is sealed with the sealing ring 5;

[0041] (2) Set the flow rate of the air pump 14, the start-stop cycle and the number of cycles of the start-stop cycle; by setting the flow rate (2L / min) of the air pump 14, the flow rate measured by the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com