Surface acoustic wave filter packaging structure and manufacturing method thereof

A packaging structure, surface acoustic wave technology, applied in electrical components, impedance networks, etc., can solve problems such as failure to improve, simplify the production process, and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The advantages and spirit of the present invention can be further understood through the following detailed description of the invention and the accompanying drawings. The manufacture and use of the preferred embodiment of the present invention are described in detail as follows. It must be understood that the present invention provides many applicable innovative concepts that can be broadly implemented within a particular background. This specific embodiment is only shown in a specific way to make and use the invention, but does not limit the scope of the invention.

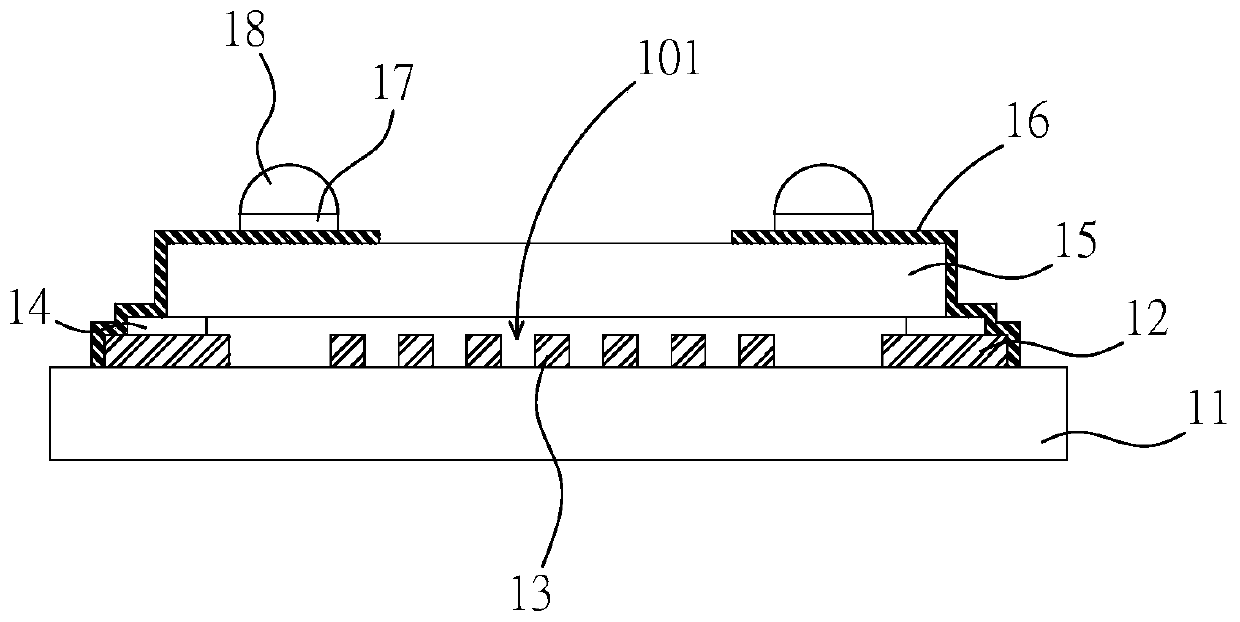

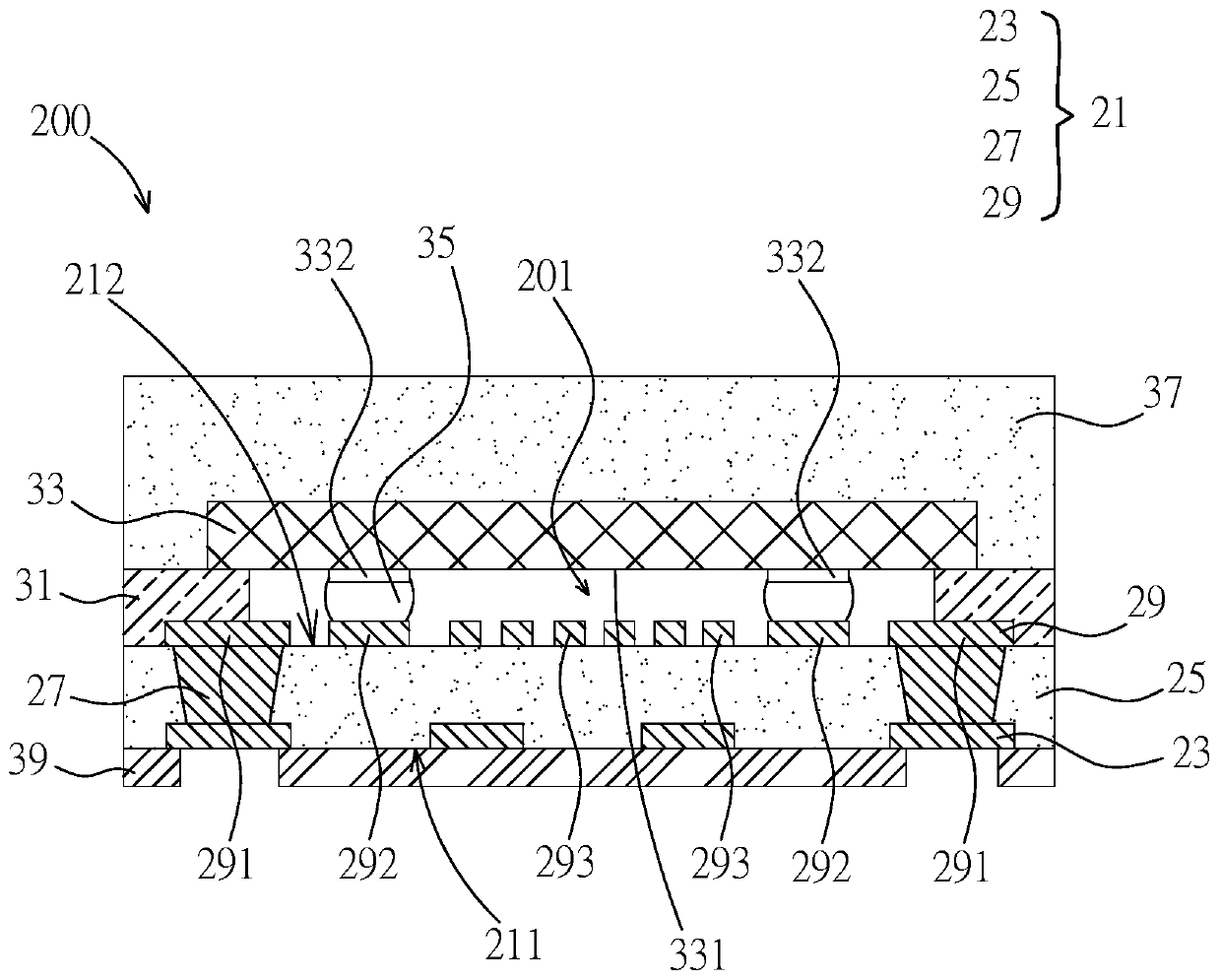

[0058] Please refer to the figure, the surface acoustic wave filter package structure 200 according to the preferred embodiment of the present invention includes a dielectric substrate 21, a chip 33, a polymer sealing frame 31, a molding layer 37 and a patterned protective layer 39 .

[0059] The dielectric substrate 21 has a dielectric layer 25 , a first patterned conductive layer 23 , a second pattern...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com