Low-temperature starting device and method for fuel cell system

A fuel cell system and starting device technology, which is applied to fuel cells, fuel cell additives, fuel cell heat exchange, etc., can solve the problems of low temperature starting of fuel cells, reduced battery efficiency, and impact on fuel cell performance and fuel cell life. , to avoid the performance damage of the fuel cell, easy operation and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

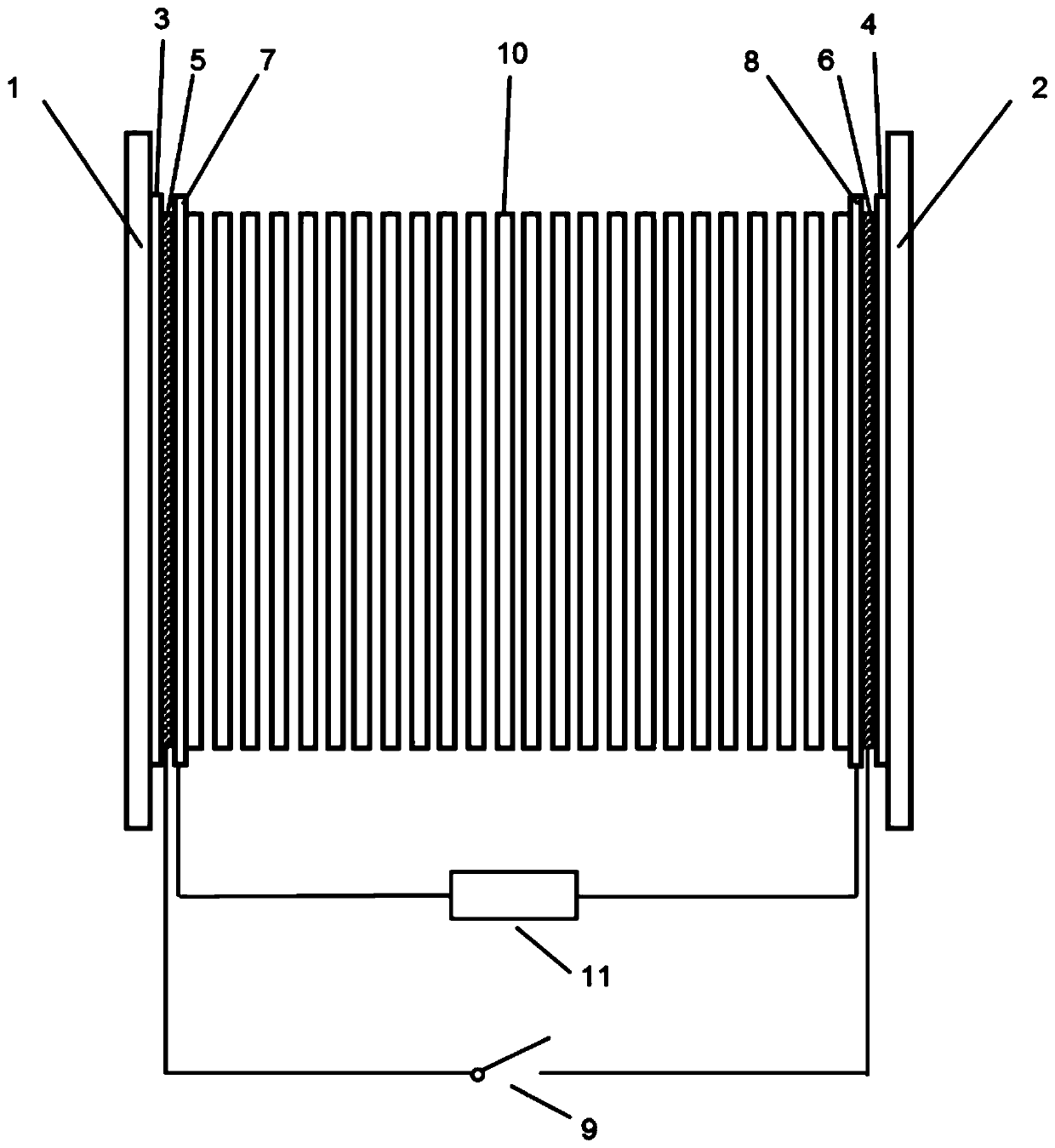

[0047] Such as figure 1 The low-temperature starting device for a fuel cell system shown includes an electronic switch 9, a fuel cell system DCDC controller 11, and an anode end plate 1, an anode insulation plate 3, an anode heating resistor 5, an anode current collector plate 7, Fuel cell stack 10, cathode current collecting plate 8, cathode heating resistor 6, cathode insulating plate 4, cathode end plate 2, fuel cell system DCDC controller; and anode heating resistor 5, anode current collecting plate 7, fuel cell stack 10. Cathode current collector 8, cathode heating resistor 6 and electronic switch 9 constitute a heating circuit; anode current collector 7, fuel cell stack 10, cathode current collector 8 and fuel cell system DCDC controller 11 constitute a control circuit;

[0048] Wherein, the resistance values of the anode heating resistor 5 and the cathode heating resistor 6 are both 0.01Ω, the thickness of the anode and cathode insulation plates is 4 mm, and the fuel ...

Embodiment 2

[0050] A method for starting a fuel cell system at low temperature based on the device in Embodiment 1, comprising the following steps:

[0051] 1) The fuel cell system receives the start signal, detects that the external environment temperature is -30°C, starts the cold start procedure, and closes the electronic switch 9 to connect to the heating circuit;

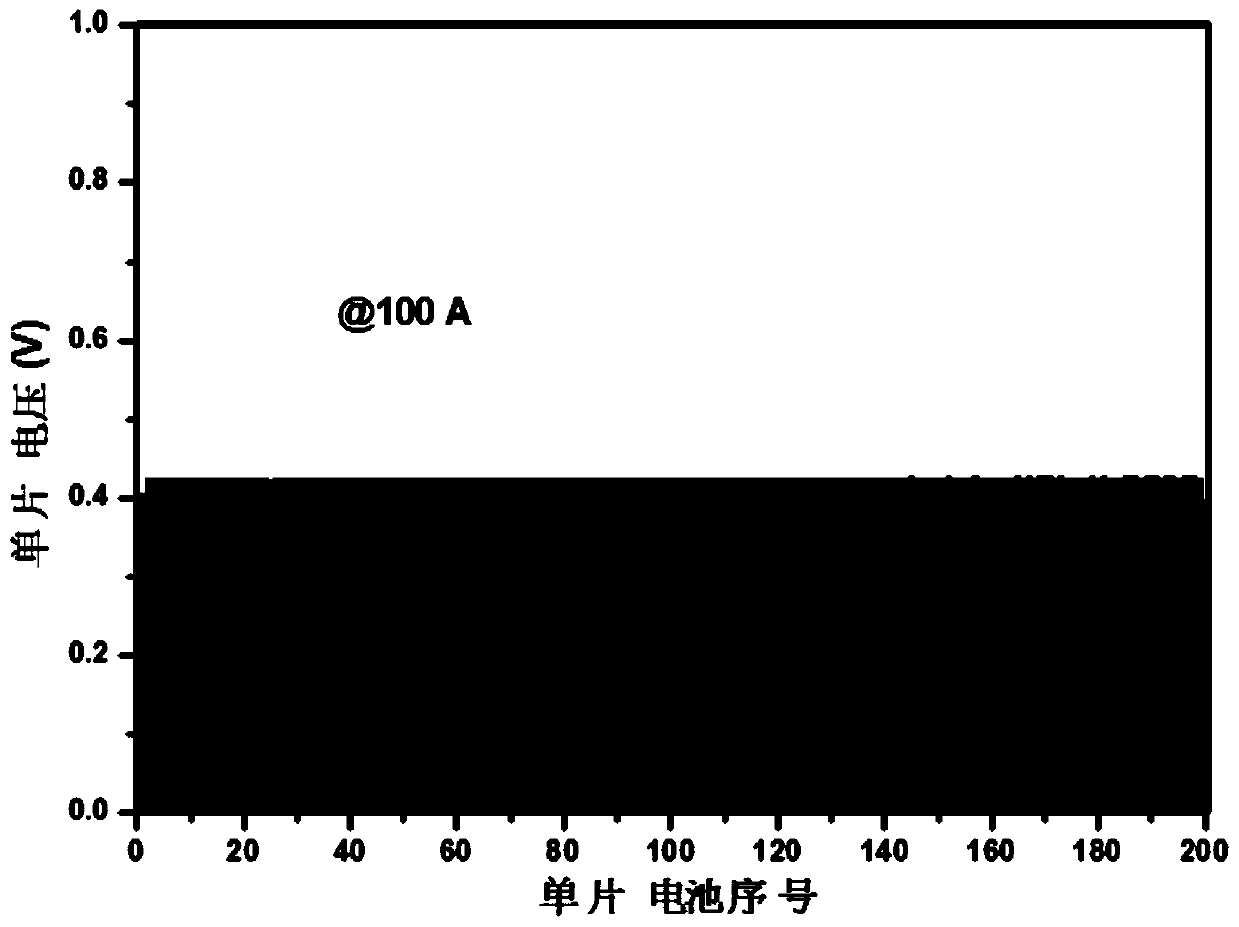

[0052] 2) The output current of the fuel cell stack 10 is set to 100A by the fuel cell system DCDC controller 11, the anode heating resistor 5 and the cathode heating resistor 6 generate heat under the action of the output voltage of the fuel cell stack 10, and heat the anode end plate 1 1. The cathode end plate 2 and the single-chip battery on the cathode and anode sides of the fuel cell stack 10 are heated with a heating power of 100W until the air temperature at the cathode outlet of the fuel cell stack 10 reaches -20°C;

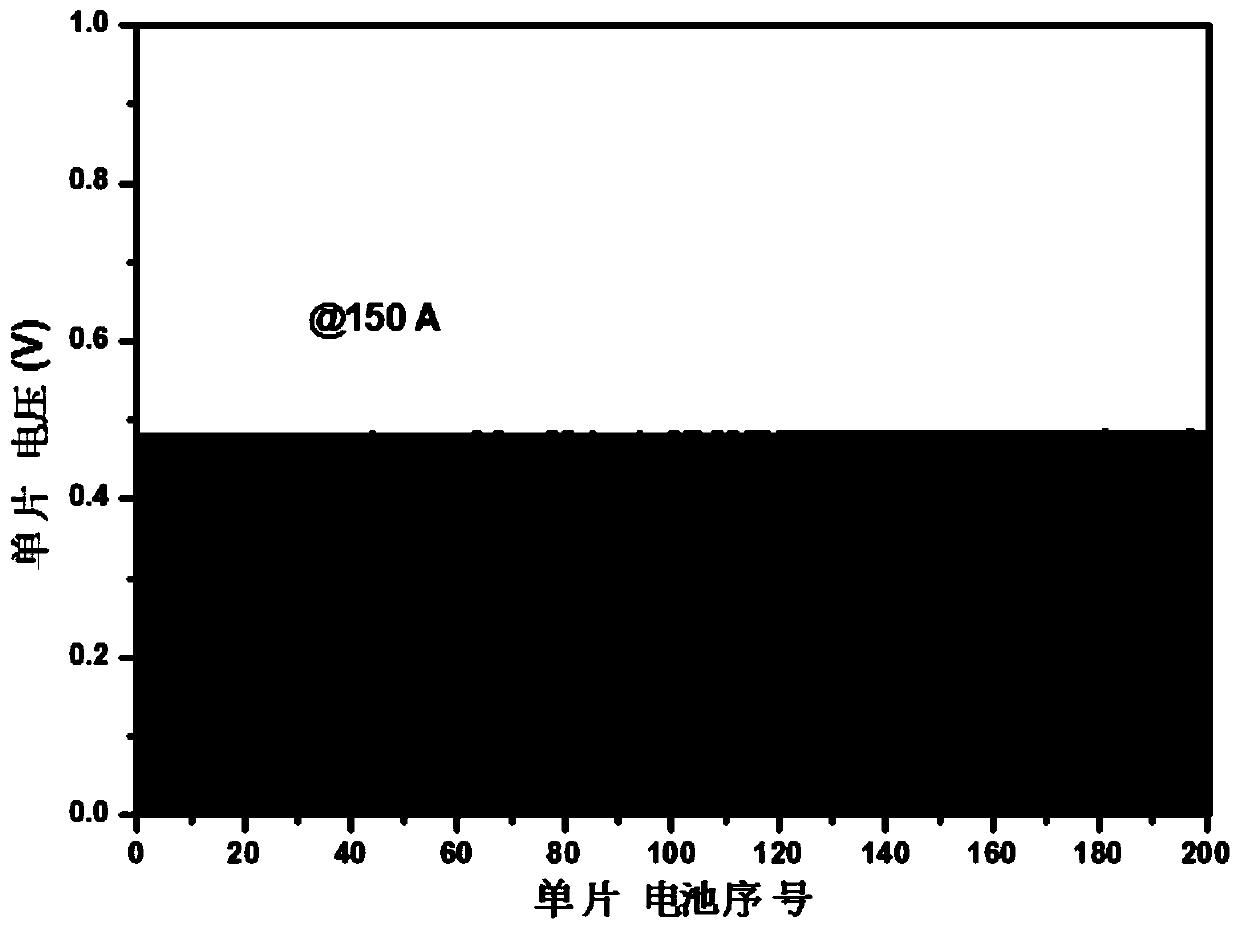

[0053] 3) The output current of the fuel cell stack 10 is set to 150A through the DCDC controller ...

Embodiment 3

[0058] In the low-temperature start-up device of the fuel cell system in this embodiment, the resistance values of the anode heating resistor 5 and the cathode heating resistor 6 are both 0.005Ω, the thickness of the anode and cathode insulating plates are both 1 mm, and the fuel cell stack 10 includes 100 single cells. All the other are with embodiment 1.

[0059] A method for starting a fuel cell system at low temperature based on the above device, comprising the following steps:

[0060] 1) Close the electronic switch 9 to communicate with the heating circuit;

[0061] 2) Set the cycle temperature threshold, the end point temperature threshold and the output current, so that the anode heating resistor 5 and the cathode heating resistor 6 heat the monolithic cells on the cathode and anode sides of the fuel cell stack 10 until the outlet temperature of the oxidant reaches the cycle temperature threshold;

[0062] 3) Determine whether the outlet temperature of the oxidant h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com