CO2 corrosion prediction plate establishing method considering multiple factors

A technology for establishing methods and predicting graphs, applied in design optimization/simulation, etc., can solve problems such as corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

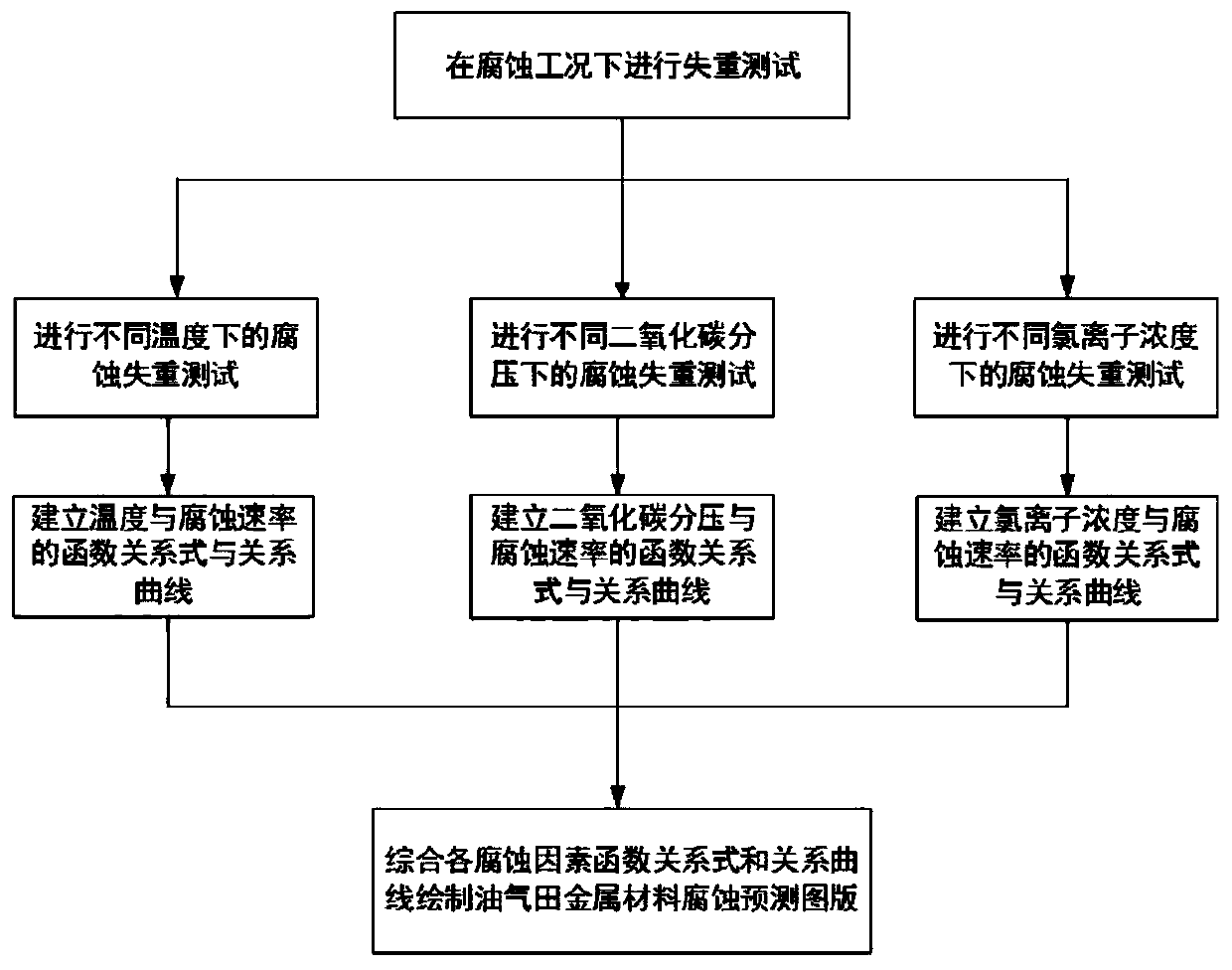

Method used

Image

Examples

Embodiment example

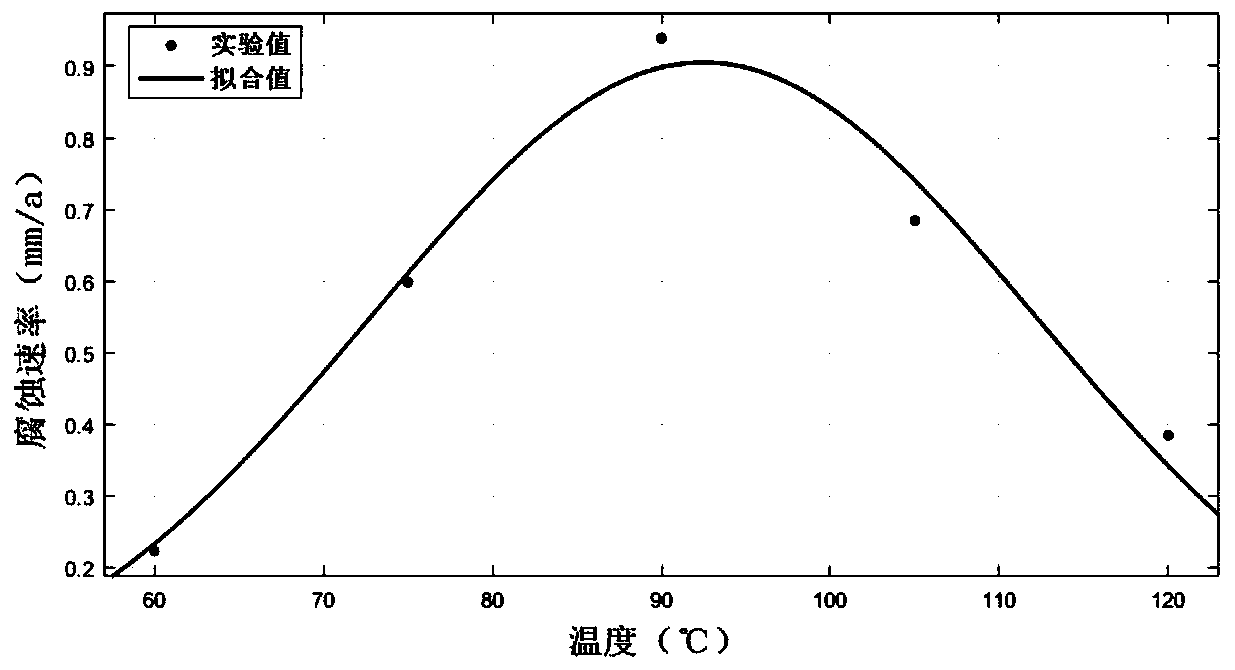

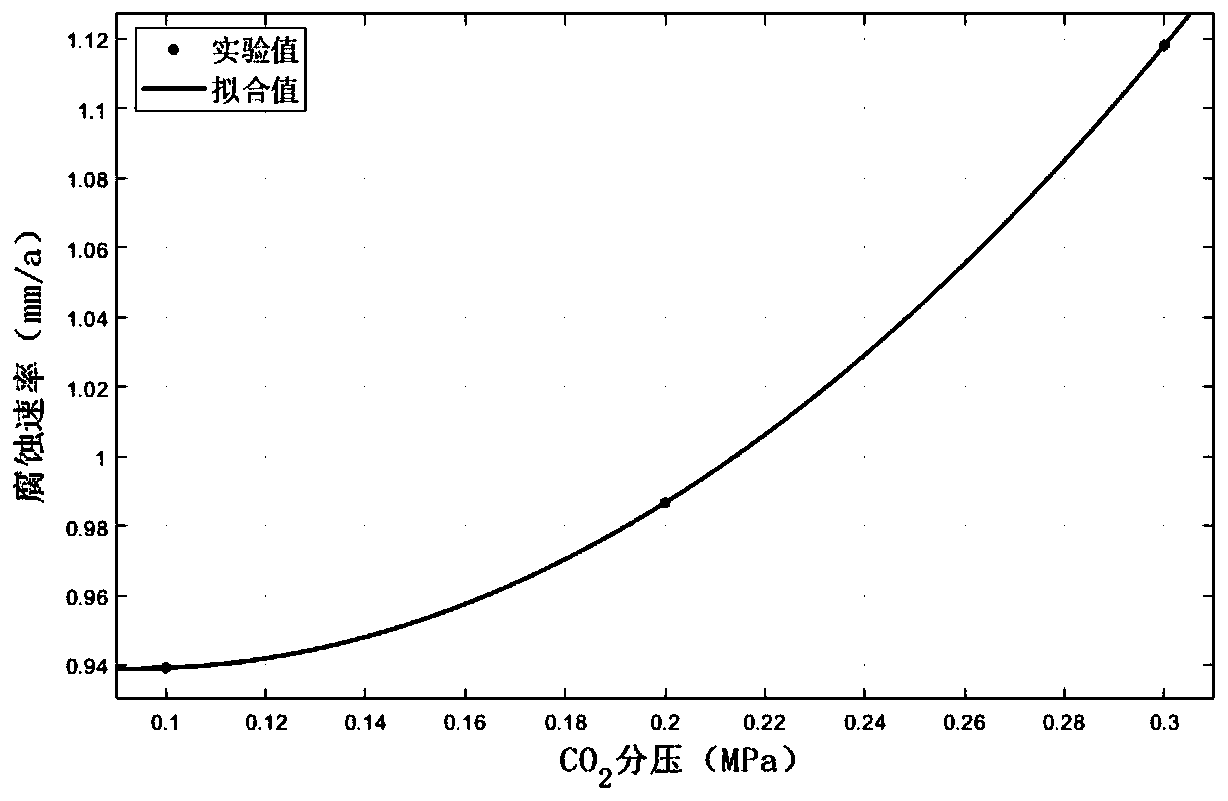

[0036] Simulate the actual working conditions of the XX oilfield and draw the corrosion prediction chart for the D-grade steel bar. The working conditions are as follows: wellbore temperature (60℃~120℃), CO 2 Partial pressure (0.1MPa~0.3MPa), chloride ion concentration (1000ppm~3000ppm), the specific implementation steps are as follows:

[0037] Step 1: Determine the parameter range of various influencing factors according to the actual working conditions of XX oilfield, among which the temperature parameters are 60℃, 75℃, 90℃, 105℃, 120℃, CO 2 The partial pressure parameters are 0.1MPa, 0.2MP, 0.3MPa and the chloride ion concentration parameters are 1000ppm, 2000ppm, 3000ppm;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com