2-color formed lens

A technology for lenses and molded products, applied in the fields of lenses, optics, instruments, etc., can solve the problems of poor appearance, easy cracks, and no hard coating film formed by two-color formed lenses, so as to suppress poor appearance, cracks, and save manpower Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0087] Hereinafter, embodiments of the present invention will be described with reference to the accompanying drawings. In the following embodiments, although various limitations are made to constituent elements, types, combinations, shapes, relative arrangements, etc., these are merely examples, and the present invention is not intended to limited to this.

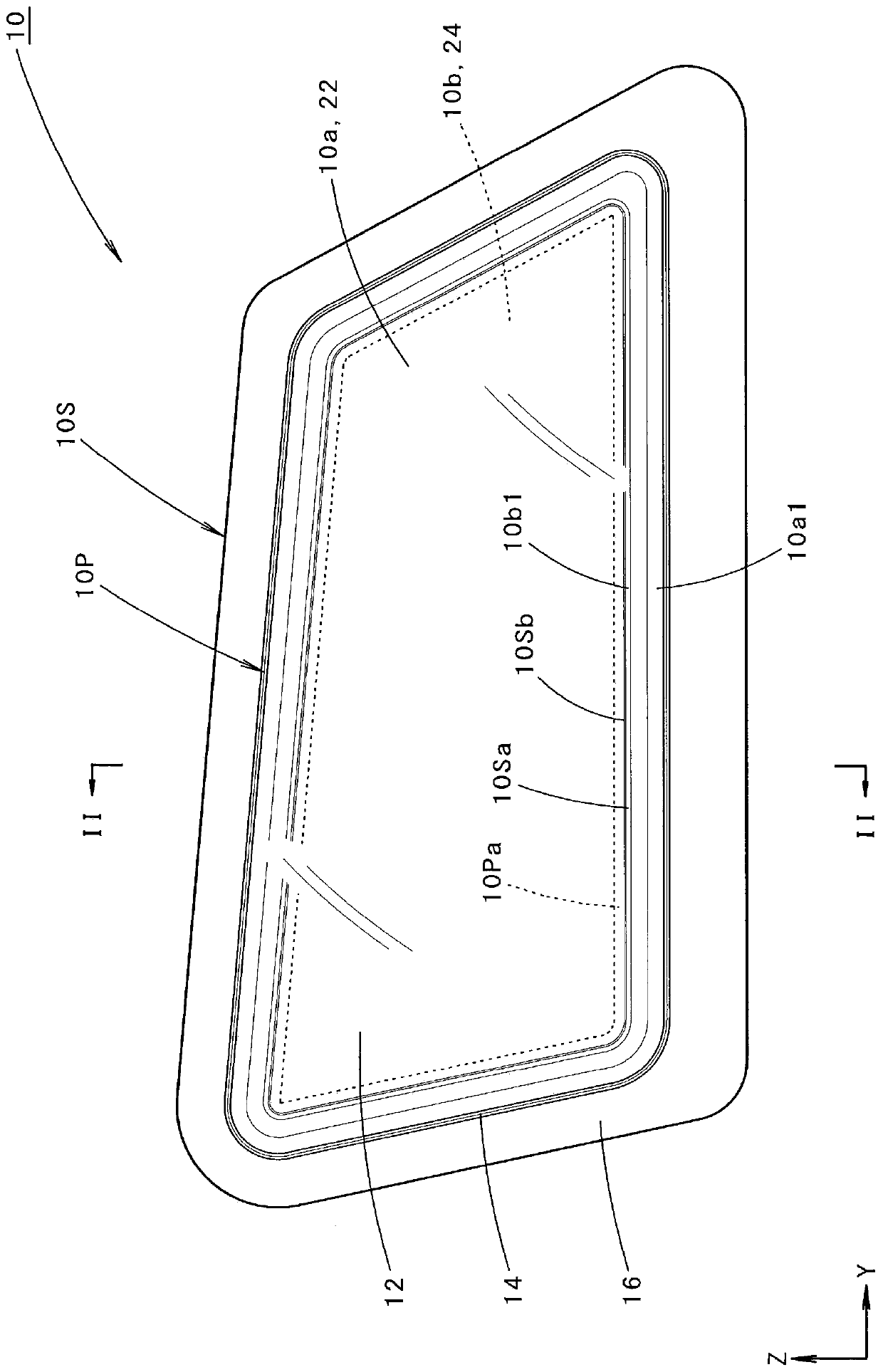

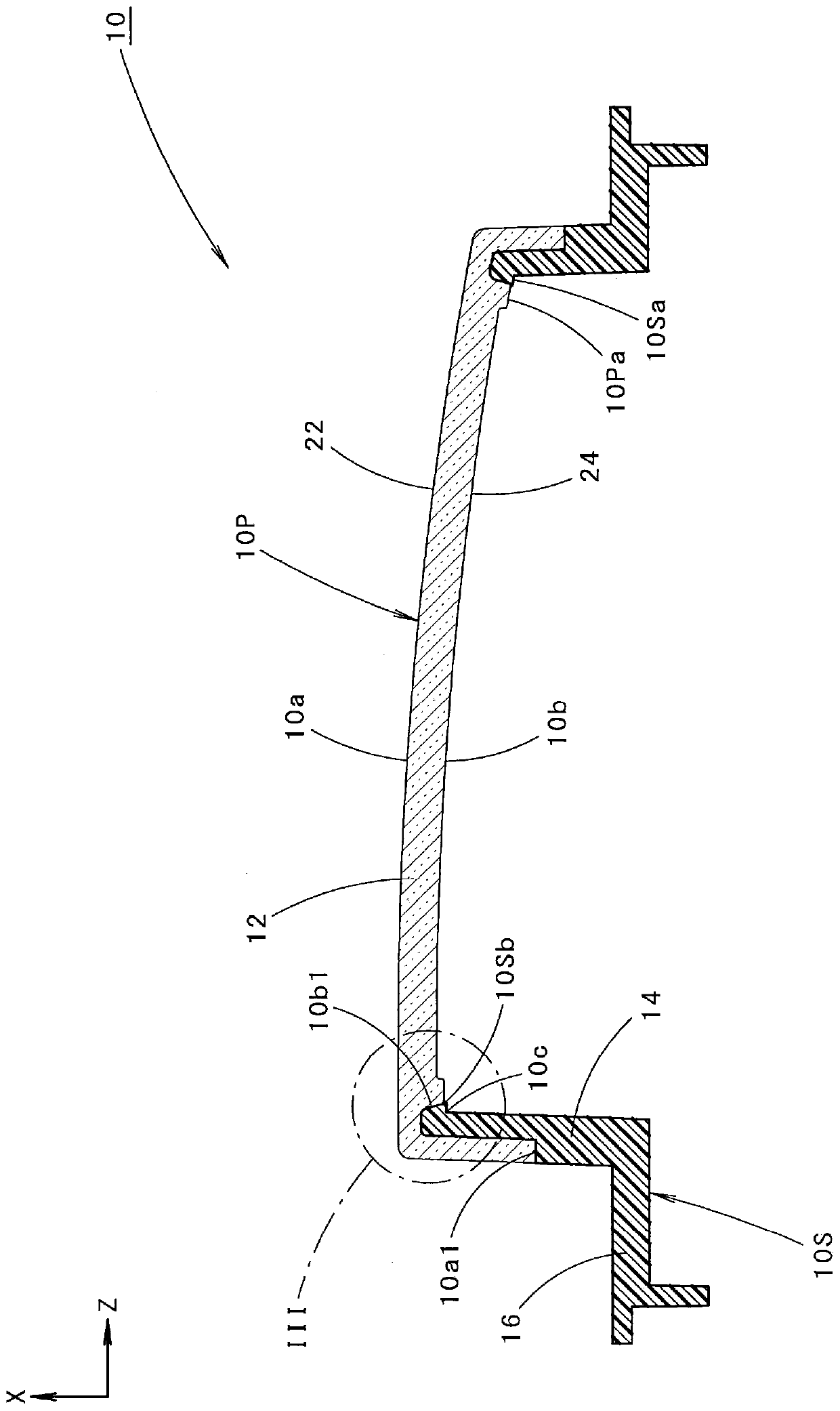

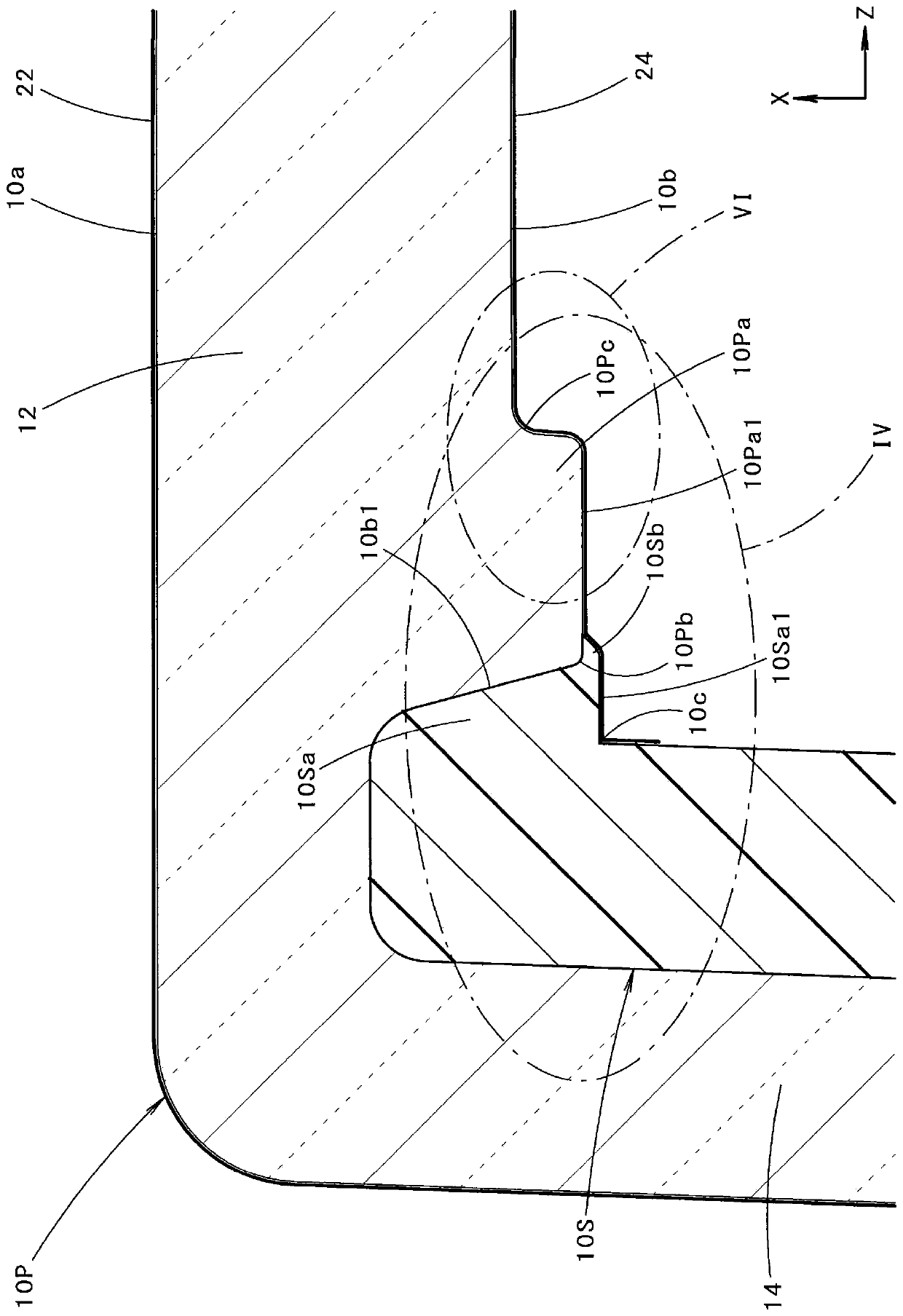

[0088] figure 1 It is a front view showing a two-color forming lens according to an embodiment of the present invention, figure 2 yes figure 1 The II-II line sectional view.

[0089] In the above figure, the direction indicated by X is the "front" of the two-color forming lens 10, and the direction indicated by Y is the "left direction" perpendicular to the "front" (in the front view of the lens, it is "right direction"). ”), and the direction represented by Z is the “upward direction”. The same applies to figures other than the above.

[0090] like figure 1 As shown, the two-color molded lens 10 according to this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com