Ultrasonic cleaner liquid crystal display screen detection device and method

A technology of liquid crystal display screen and detection method, which is applied in the directions of measuring devices, cleaning methods and utensils, cleaning methods using liquids, etc., and can solve the problems of low detection integrity, manual detection, missed detection, incomplete detection of control functions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

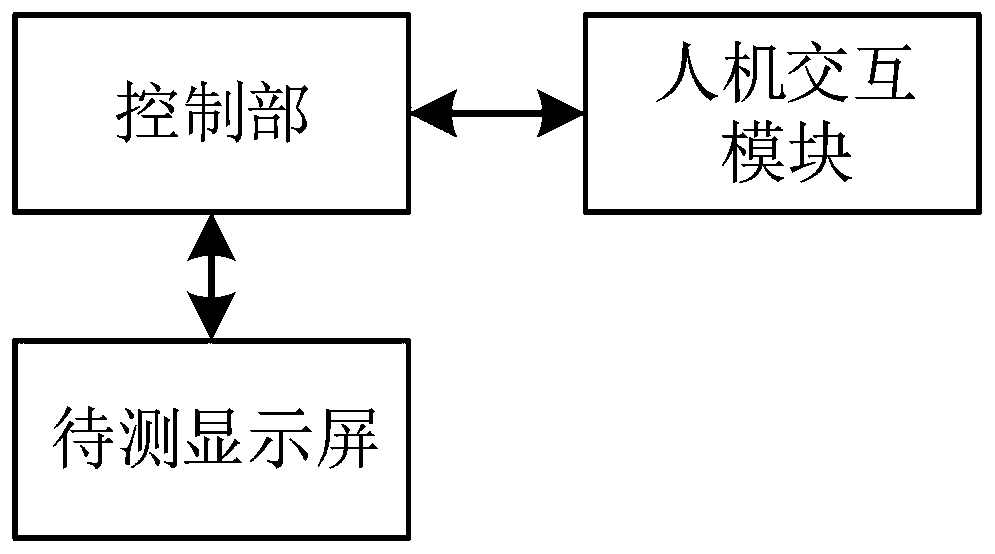

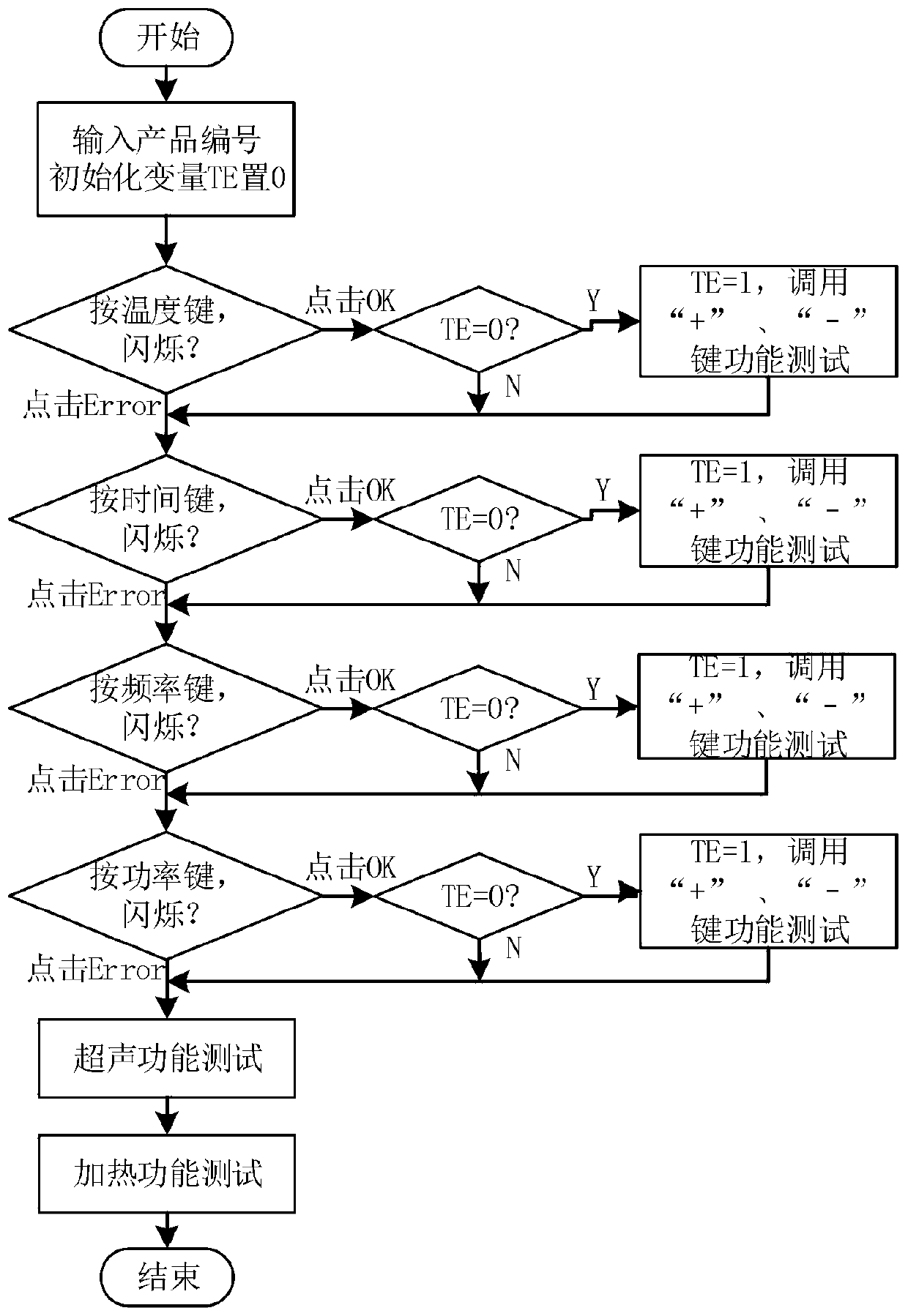

[0028] In order to achieve the above purpose, an embodiment of the present invention provides a liquid crystal display detection device and method for an ultrasonic cleaning machine. Such as Figure 1 to Figure 2 As shown, the ultrasonic cleaning machine liquid crystal display detection device and method include: a signal detection module, a control unit and a human-computer interaction module, wherein,

[0029] The signal detection module is used to connect to the liquid crystal display to be tested; the signal detection module includes a temperature detection module, a time detection module, a frequency detection module, a power detection module, an ultrasonic function detection module and a heating function detection m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com