Composite flame-retardant solid wood floor and preparation process thereof

A technology of solid wood flooring and preparation technology, applied in the field of wooden flooring, can solve problems such as unfavorable health of residents, wooden flooring that cannot satisfy consumers, excessive formaldehyde, etc., to reduce water soaking, good foot feel and touch, and improve antibacterial performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

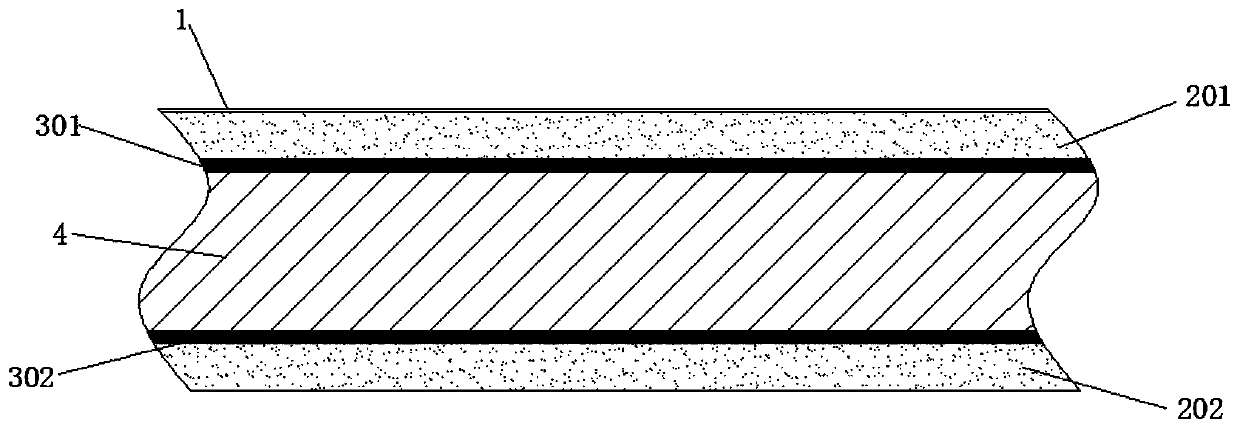

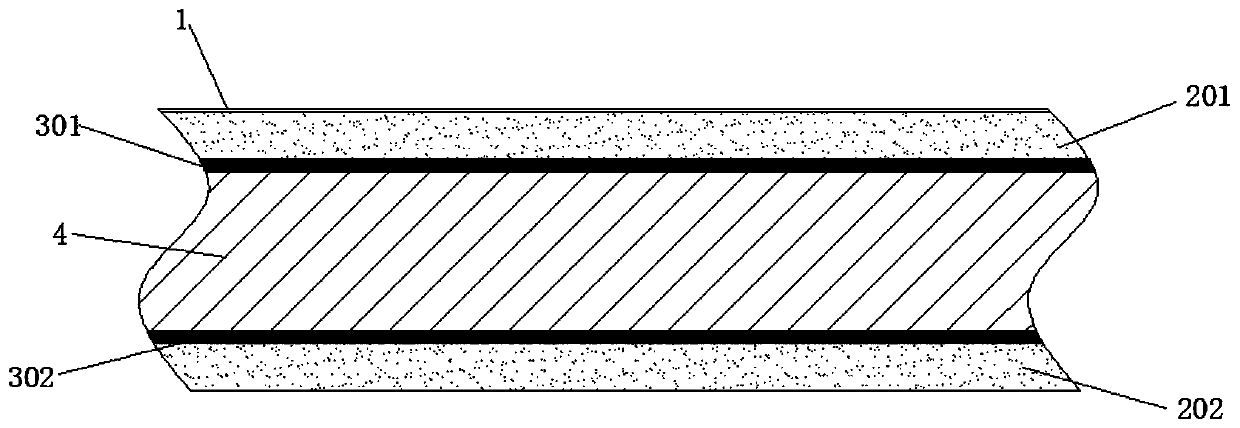

[0032] A composite flame-retardant solid wood floor. The composite flame-retardant solid wood floor is sequentially provided with a UV topcoat layer 1, a carbonized flame-retardant board layer 201, a flame-retardant layer 301, a solid wood flame-retardant board layer 4, and a flame-retardant board layer from top to bottom. Flame-retardant layer 2 302, carbonized flame-retardant plate layer 2 202; carbonized flame-retardant plate layer 1 201, flame-retardant layer 1 301, solid wood flame-retardant plate layer 4, flame-retardant layer 2 302, and the thickness of carbonized flame-retardant plate layer 2 202 in sequence 2.4mm, 0.6mm, 8mm, 0.6mm, 2.4mm.

[0033] Wherein, the topcoat used for the topcoat layer 1 is a transparent UV paint.

[0034] The carbonized flame-retardant sheets used in the first layer 201 of the carbonized flame-retardant sheet and the second layer 202 of the carbonized flame-retardant sheet are prepared by the following method:

[0035] (1) Process the wood i...

Embodiment 2

[0049] A composite flame-retardant solid wood floor. The composite flame-retardant solid wood floor is sequentially provided with a topcoat layer 1, a carbonized flame-retardant board layer 201, a flame-retardant layer 301, a solid wood flame-retardant board layer 4, and a flame-retardant board layer from top to bottom. Layer 2 302, carbonized flame-retardant plate layer 2 202; carbonized flame-retardant plate layer 1 201, flame-retardant layer 1 301, solid wood flame-retardant plate layer 4, flame-retardant layer 2 302, and the thicknesses of carbonized flame-retardant plate layer 2 202 are as follows: 2.6mm, 0.7mm, 9mm, 0.7mm, 2.6mm.

[0050] Wherein, the topcoat used for the topcoat layer is a transparent UV paint.

[0051] The carbonized flame-retardant sheets used in the first layer 201 of the carbonized flame-retardant sheet and the second layer 202 of the carbonized flame-retardant sheet are prepared by the following method:

[0052] (1) Process the wood into planks; d...

Embodiment 3

[0066] A composite flame-retardant solid wood floor. The composite flame-retardant solid wood floor is sequentially provided with a topcoat layer 1, a carbonized flame-retardant board layer 201, a flame-retardant layer 301, a solid wood flame-retardant board layer 4, and a flame-retardant board layer from top to bottom. Layer 2 302, carbonized flame-retardant plate layer 2 202; carbonized flame-retardant plate layer 1 201, flame-retardant layer 1 301, solid wood flame-retardant plate layer 4, flame-retardant layer 2 302, and the thicknesses of carbonized flame-retardant plate layer 2 202 are as follows: 2mm, 0.5mm, 8mm, 0.5mm, 2mm.

[0067] Wherein, the topcoat used for the topcoat layer is transparent PU paint.

[0068] The carbonized flame-retardant sheets used in the first layer 201 of the carbonized flame-retardant sheet and the second layer 202 of the carbonized flame-retardant sheet are prepared by the following method:

[0069] (1) Process the wood into planks; dry the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com