A method for manufacturing moldless bare-fired foamed ceramics

A technology of foamed ceramics and a manufacturing method, which is applied to ceramic products, manufacturing tools, ceramic molding machines, etc., can solve the problems of high energy consumption of foamed ceramics, improve production efficiency, overcome poor bonding ability of contact surfaces, and reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to clearly illustrate the technical features of the present solution, the present application will be described in detail below through specific implementation modes.

[0025] This application illustrates the specific implementation of this application through the following examples of synthesis and characterization. The specific synthesis steps are as follows:

[0026] S1 Weighing material: Weigh the raw materials of foamed ceramics according to the parts by mass;

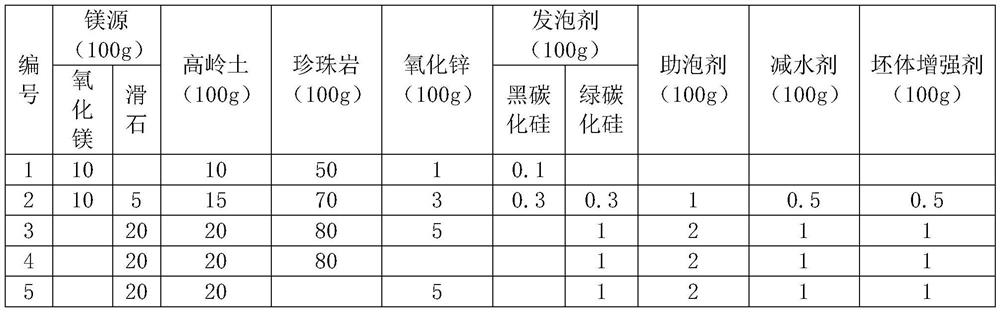

[0027] The raw materials are as shown in Table 1:

[0028] Table 1:

[0029]

[0030] S2 Ball milling of foamed ceramic raw materials: Wet ball milling is adopted, and the mud control process indicators are: fineness 2.0±0.2%, flow rate 39±15”, specific gravity 1.50±0.05, moisture 38±2%; mud passes through 20 meshes in sequence after passing , 80 mesh, 100 mesh three sieves, and aged and homogenized for not less than 48 hours;

[0031] S3 Spray drying: The foamed ceramic raw material slurry i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com