Automatic unhooking device, lifting hook and method

A technology of automatic decoupling and hooking, which is applied in the directions of transportation and packaging, load hanging components, etc., can solve the problems of manually opening the pins and being unable to climb up, and achieves the effect of improving strength, reducing the use of manpower and saving investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

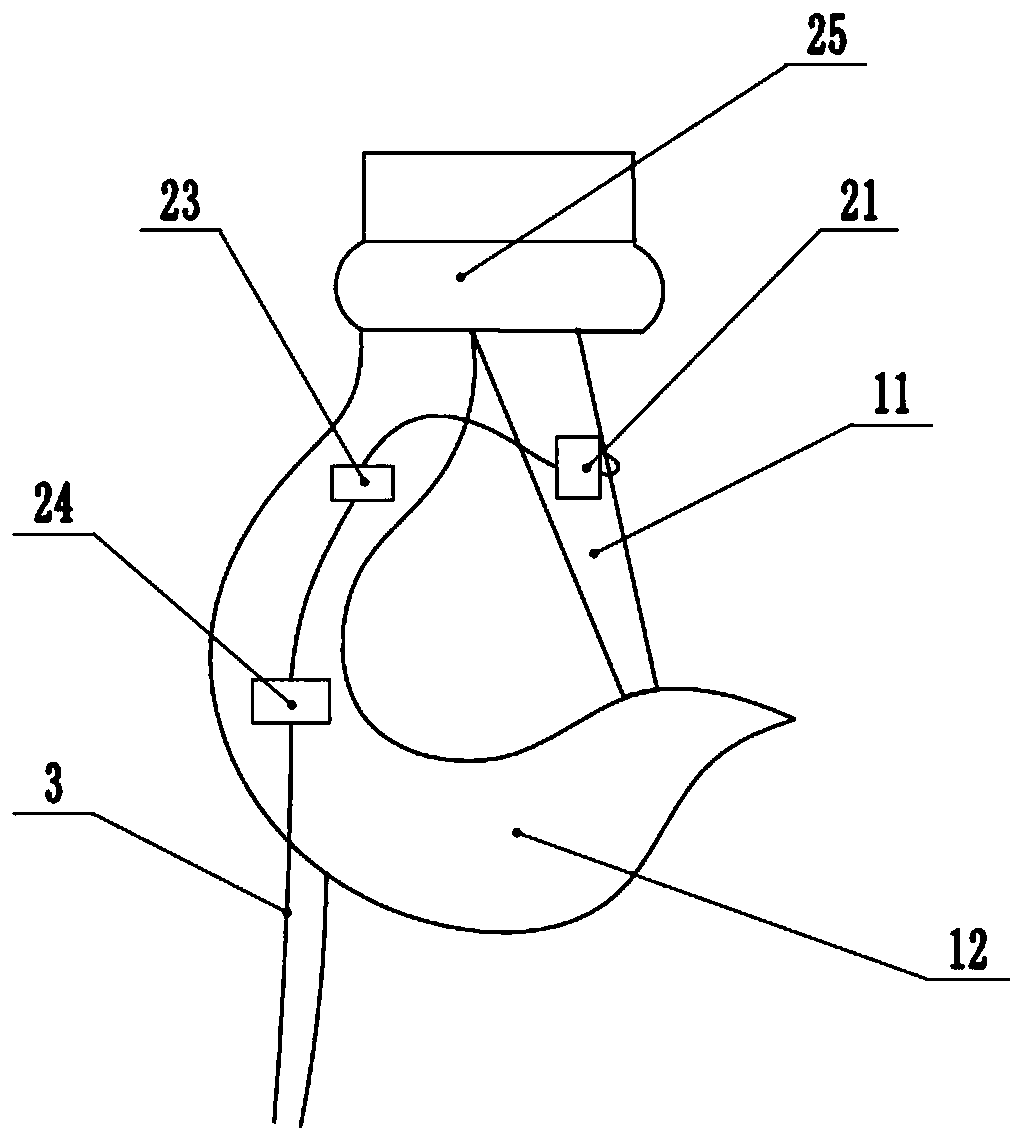

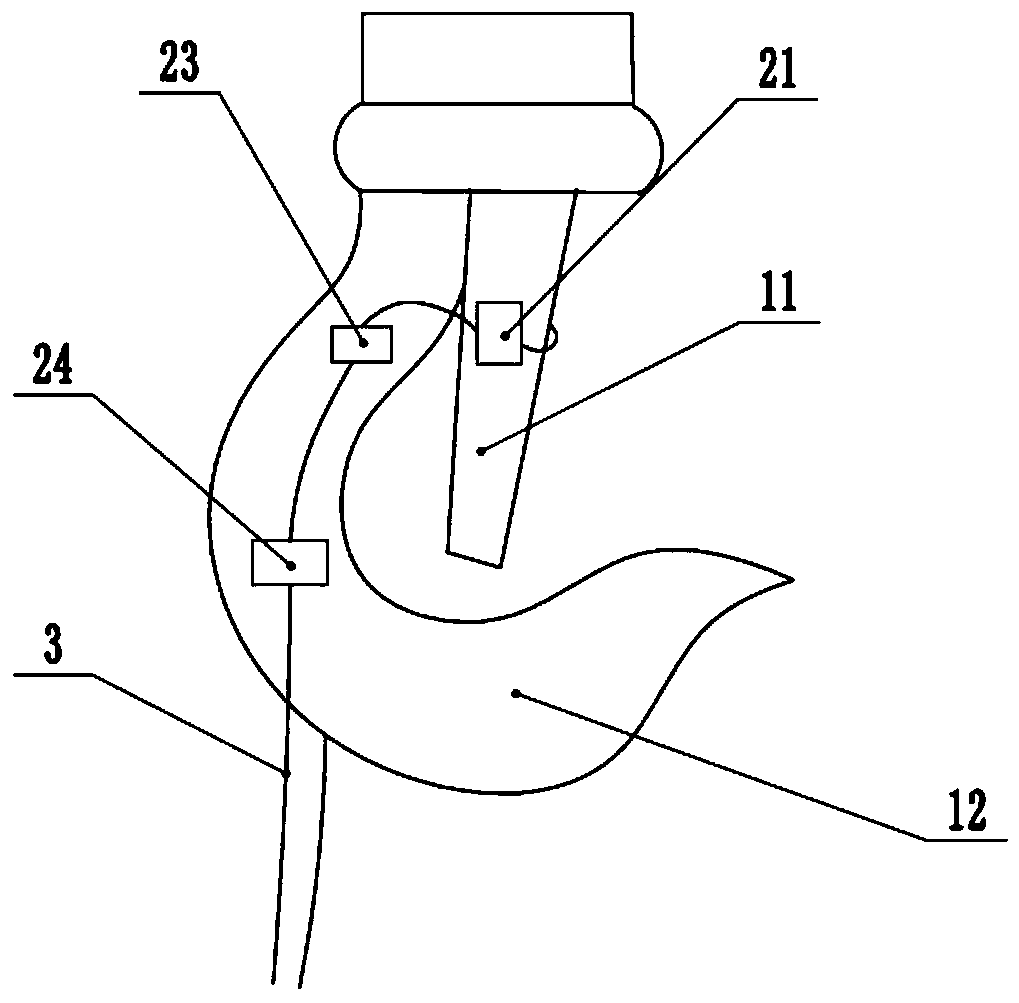

[0037] Firstly, this embodiment discloses an automatic decoupling device, which includes a plurality of perforated limiters fixedly connected to the hook body 10, and a flexible rope-like member passing through the plurality of limiters;

[0038] The arrangement shape of a plurality of position-limiting parts is adapted to the shape of the hook body 10, and the position-limiting part at the first position in the plurality of position-limiting parts is fixed to the movable part 11 of the suspension hook body 10; When a force is applied in a direction away from the first position limiting member, the flexible rope-like member can pull the movable part 11 of the hook body 10 .

[0039] It can be understood that, in this embodiment, there are 6 limiters, and the 6 limiters are distributed on the two sides of the hook body 10 , and the flexible rope-like member is a steel wire rope 3 .

[0040] Among the 6 limiters, there are 4 limiters located outside the first position. It should...

Embodiment 2

[0052] This embodiment discloses an automatic unhooking hook, which includes a hook body 10 and an automatic unhooking device connected to the hook body 10 .

[0053] What needs to be explained in detail here is that the hook body 10 in this embodiment includes a hoop, a hook-like body 12 and a movable part 11, the hook-like body 12 is fixedly connected to the hoop, and the end of the movable part 11 is hinged and movable. One end of the movable part 11 has an elastic part between the movable part 11 and the hook 12. The movable part 11 is rod-shaped. Therefore, the movable part 11 can rotate around its hinge point reciprocatingly with its hinge point as a fulcrum.

[0054] The automatic decoupling device in this embodiment includes four stoppers with perforations that are fixedly connected to both sides of the hook pile body of the hook body 10, and two stoppers with perforations that are fixedly connected to the movable part 11 of the hook body 10. The limiting parts and the...

Embodiment 3

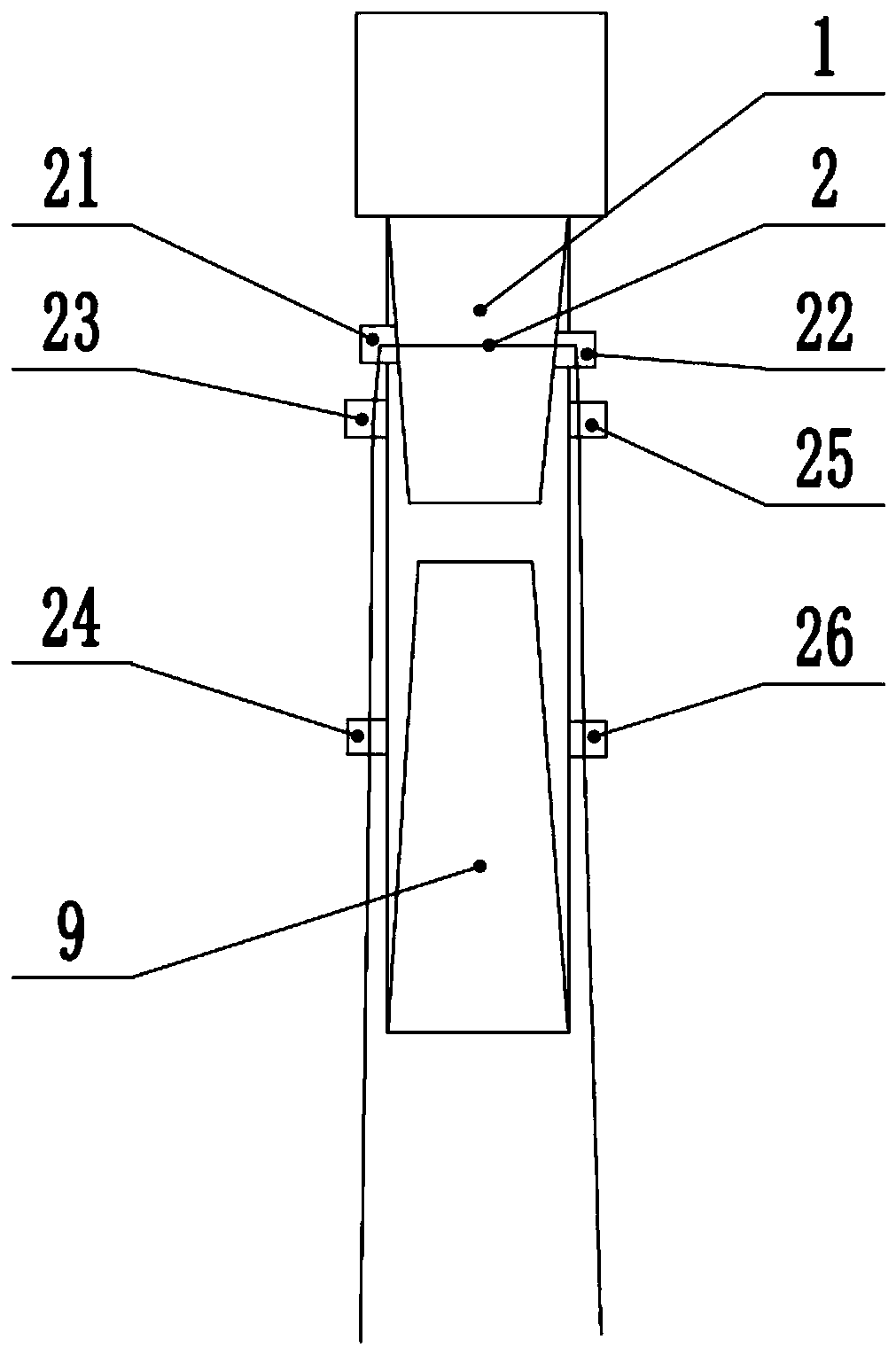

[0058] This embodiment discloses an automatic decoupling method, which adopts the automatic decoupling device as described in embodiment 1, or the automatic decoupling hook described in embodiment 2, and applies a force far away from the limit piece located at the first position to the flexible rope-like member. Direction of force, the flexible rope can pull the movable part 11 of the hook body 10 .

[0059] It also includes an automatic dragging mechanism. The automatic dragging mechanism includes a power source, a controller and a distance sensor 5 installed on the hook body 10. When the distance sensor 5 detects the distance set by the hook sensor from the ground, the power is activated. source to apply a force to the flexible cord in a direction away from the stopper at the first position.

[0060] In this embodiment, the power source is a stepper motor 5 that is easy to control, and the power source can also be selected from various forms of power sources such as pneumati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com