Automatic wheel carrying device

A technology for handling devices and wheels, applied in the directions of transportation and packaging, conveyors, mechanical conveyors, etc., can solve problems such as low efficiency and easy scratches, and achieve the effect of simple device structure, avoiding scratches and damage, and reducing manpower.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with embodiment the present invention is described in further detail:

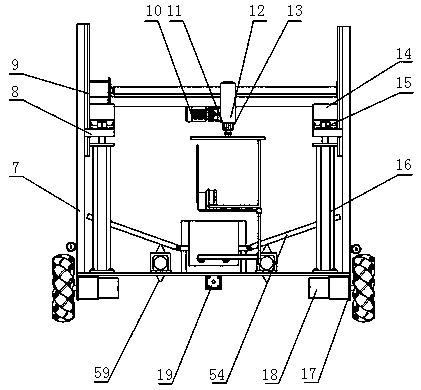

[0026] Such as figure 1 As shown, an automatic wheel transfer device according to the present invention includes a trolley frame 1 , a wheel fixing device 2 , a translation device 3 , a rotation device 4 , a hooking device 5 and a lifting device 6 . The whole device takes the trolley frame 1 as the main structure, the wheel fixing device 2 is fixedly connected to the middle position of the bottom of the trolley frame 1, the bottom of the lifting device 6 is bolted to the bottom of the trolley frame 1 and fixed on the four corners, the translation device 3 and the lifting device 6 The connection can follow the lifting device 6 to realize rising and falling, the rotating device 4 is connected under the translation device 3, the hooking device 5 is connected to the rotating device 4, and the trolley frame 1 is provided with sensors and observation devices.

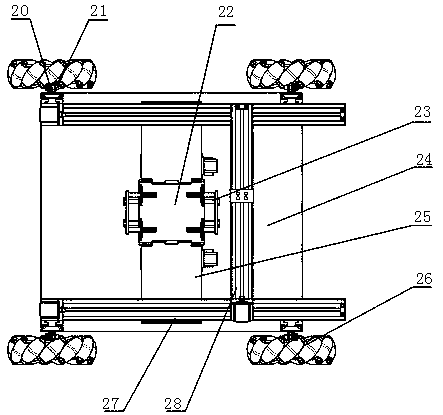

[0027] Such as figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com