Ship fender structure

A technology for ship fenders and main bodies, which is used in ship hulls, ship construction, ship cleaning devices, etc., and can solve problems such as easy damage, high cost, and inability to protect components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

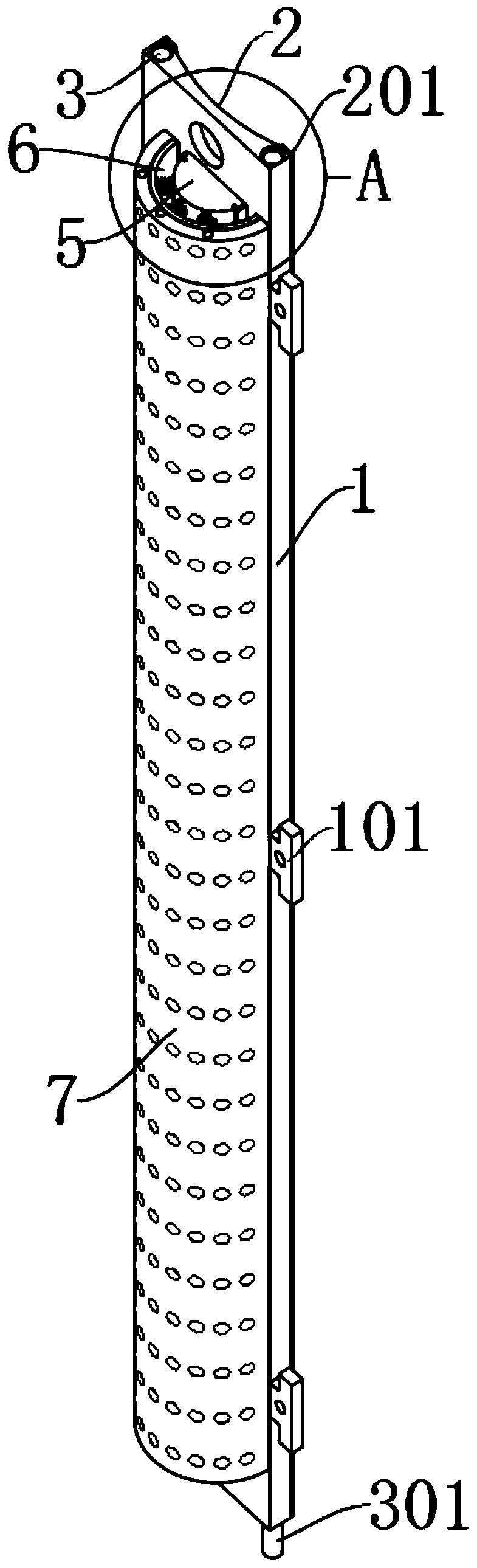

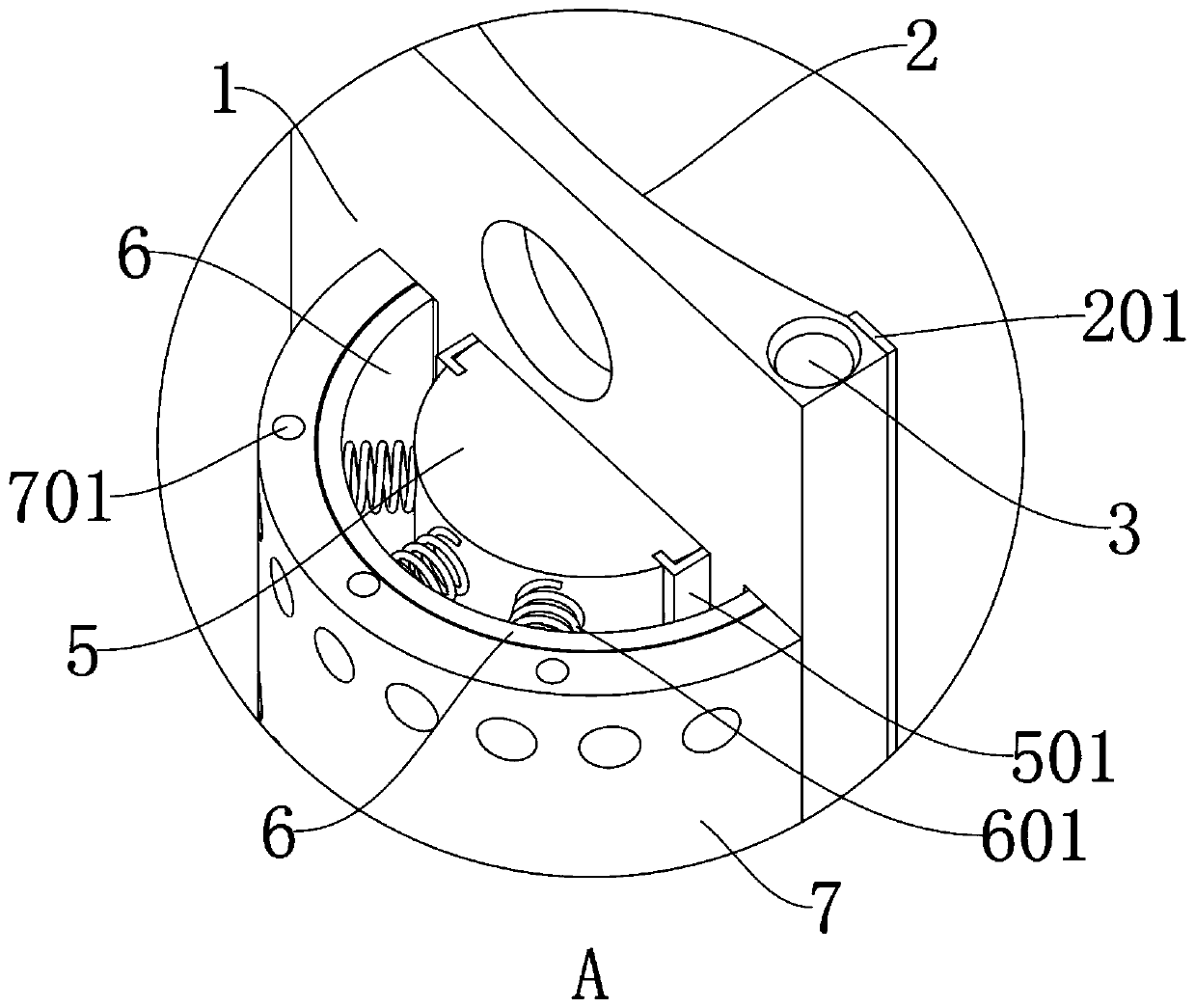

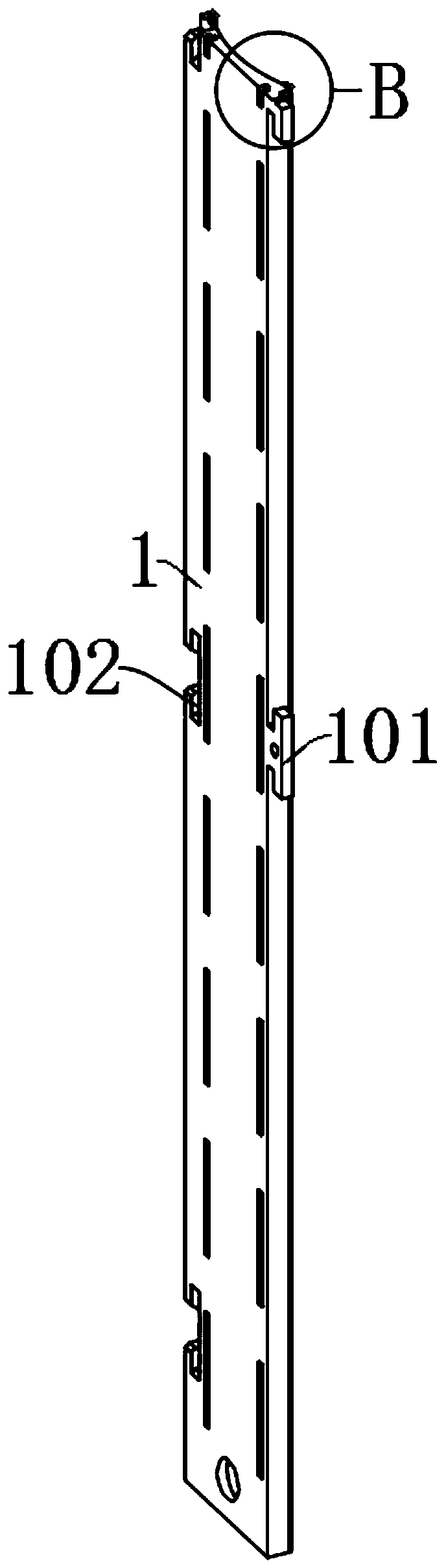

[0030] as attached figure 1 to attach Figure 8 Shown:

[0031]The invention provides a ship fender structure, comprising: a main body 1, an inner groove 2, a socket 3, a mounting groove 4, an inner part 5, an auxiliary part 6 and an outer part 7; the main body 1 is a rectangular plate structure, and the main body 1 is made of spring steel, and the connecting piece 101 and the connecting groove 102 are T-shaped structures, so that after the two are connected, bolts can be used to pass through the connecting holes of the connecting piece 101 and the connecting groove 102 to fix with the hull, so that the connecting piece 101 It cannot be separated from the inside of the connecting groove 102, so that the splicing of the main body 1 is more stable and a linkage is formed, so that when a single main body 1 is subjected to an impact force, the force can be distributed; the inner groove 2 is located in the middle of the rear end of the main body 1; The inner tank 2 includes a sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com