An automatic charging pile, a charging control system and a charging method

An automatic charging and charging control technology, which is applied to electric vehicle charging technology, charging stations, electric vehicles, etc., can solve problems such as low charging efficiency, damage to the charging gun, and user burden, and achieve improved charging efficiency, increased charging power, and The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060]The charging pile in this embodiment is the same as the charging pile in the above-described charging control system embodiment, and the difference is that the specific configuration and principles of the automatic charging pile will not be described again.

Embodiment 2

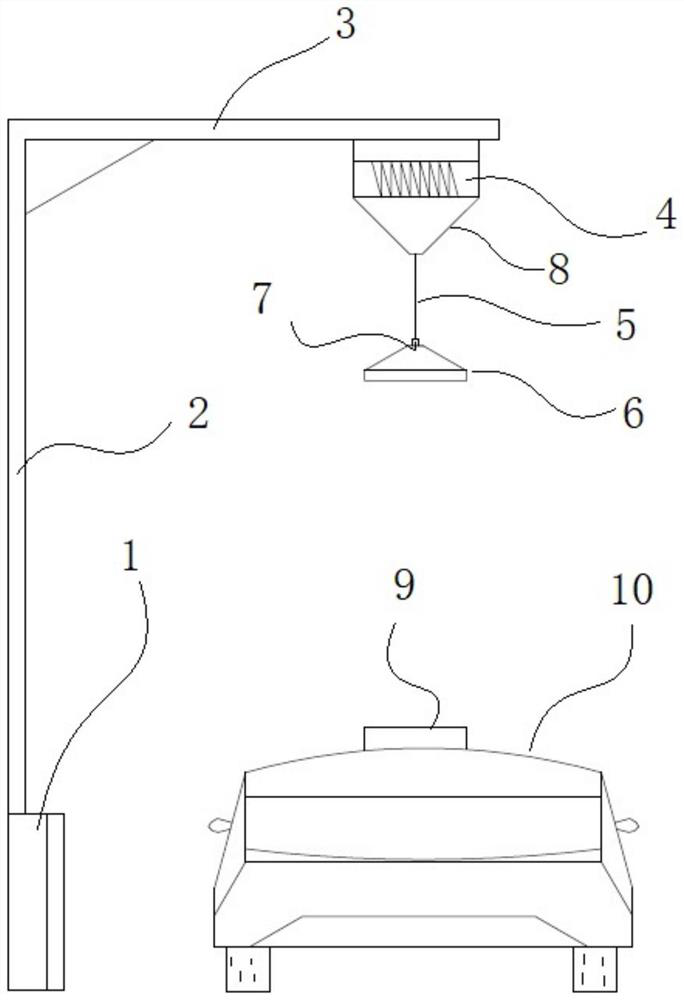

[0062]Compared with Example 1, the charging pile of Example 1 applies to indoor parking spaces such as underground garages, and also suitable for outdoor parking spaces. For some underground parking spaces or indoor parking spaces, the charging pile can also be designed, no longer set up a column, but set the charging pile to hang the top of the wall, reduce the space occupied by the ground, such asFigure 6 Indicated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com