A shot blasting system for shaft ring production

A treatment system and sand shot technology, which is applied to used abrasive treatment devices, metal processing equipment, manufacturing tools, etc., can solve the problems of poor removal effect and high frequency of replacement of consumables, so as to improve filtration efficiency and meet the use requirements. Good effect of removing impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

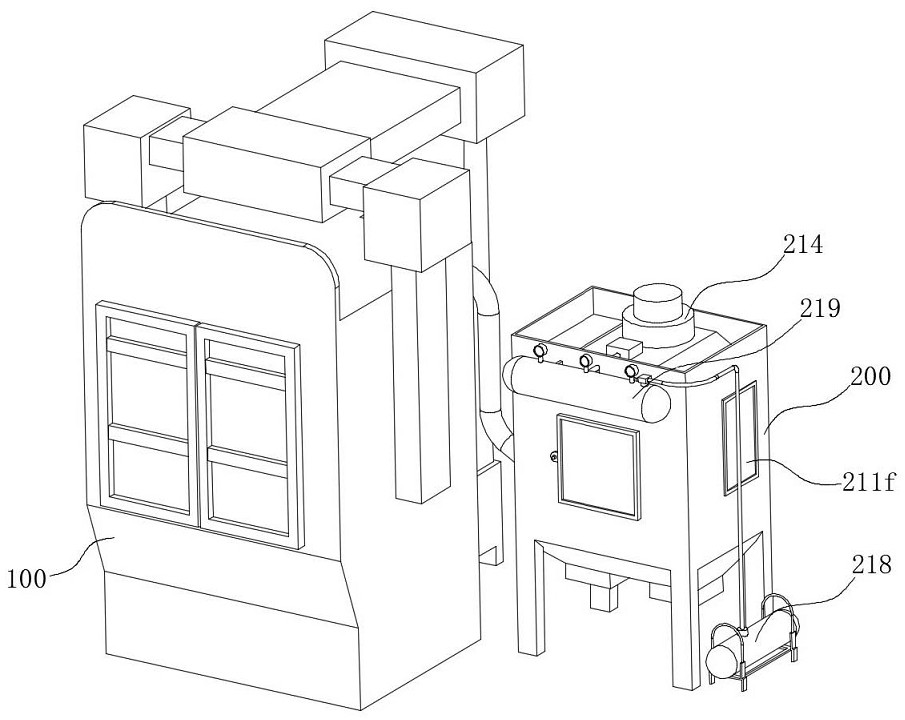

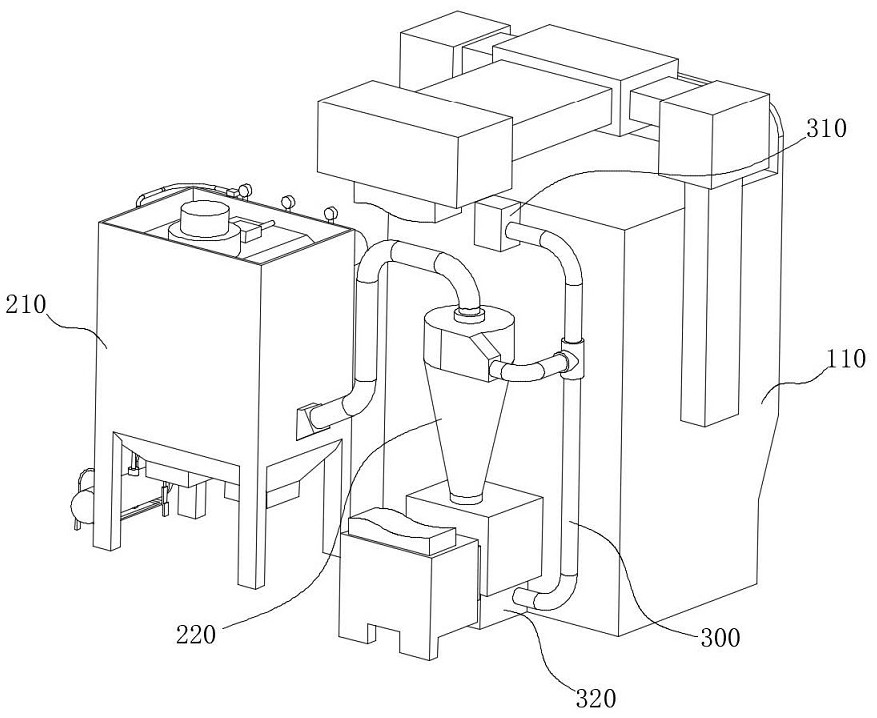

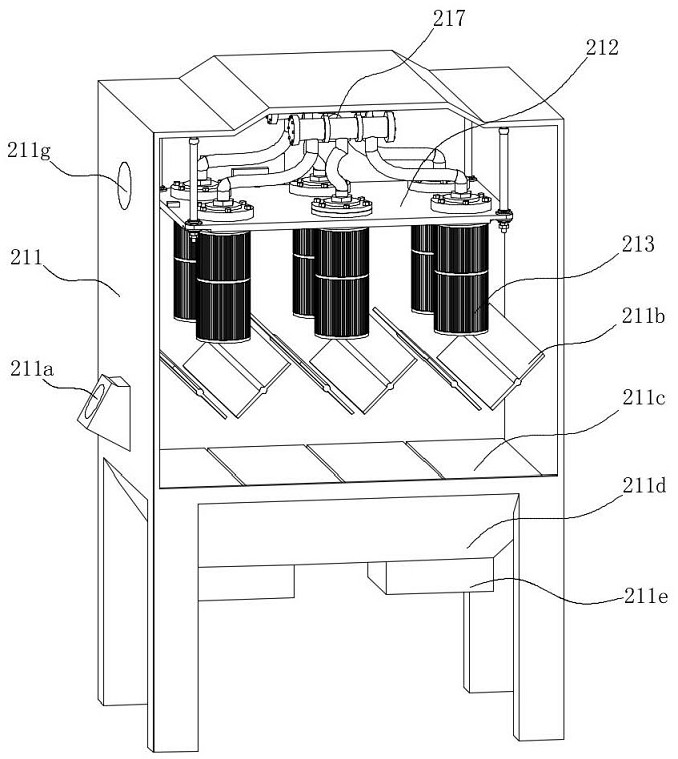

[0046] refer to Figure 1-6 , in this embodiment, a shot blasting treatment system for shaft ring production is proposed, including a shot blasting unit 100 for shaft ring shot blasting treatment and an impurity removal unit 200 for waste removal. The shot blasting unit 100 Including the shot blasting box 110, the impurity removal unit 200 includes a cyclone separator 220 and a filter cartridge dust collector 210, the feed inlet of the cyclone separator 220 is connected with the shot blasting box 110 through a waste collection pipeline 300, and the cyclone separator 220 The air outlet is connected with the air inlet of the filter cartridge dust collector 210 .

[0047] Through the setting of the shot blasting unit 100, the function of shot blasting treatment of the bearing is realized, and through the setting of the impurity removal unit 200, the function of removing the waste generated by the shot blasting unit 100 is realized. First, the cyclone separator 220 is used to real...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com