Repair welding process for nodular cast iron roller

A ductile iron and repair welding technology, applied in the field of cast iron, can solve the problems affecting the normal use of ductile iron rolls, short service life of ductile iron rolls, large repair welding deformation and residual stress, etc., so as to reduce repair welding deformation and residual stress. , high reliability repair, repair speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

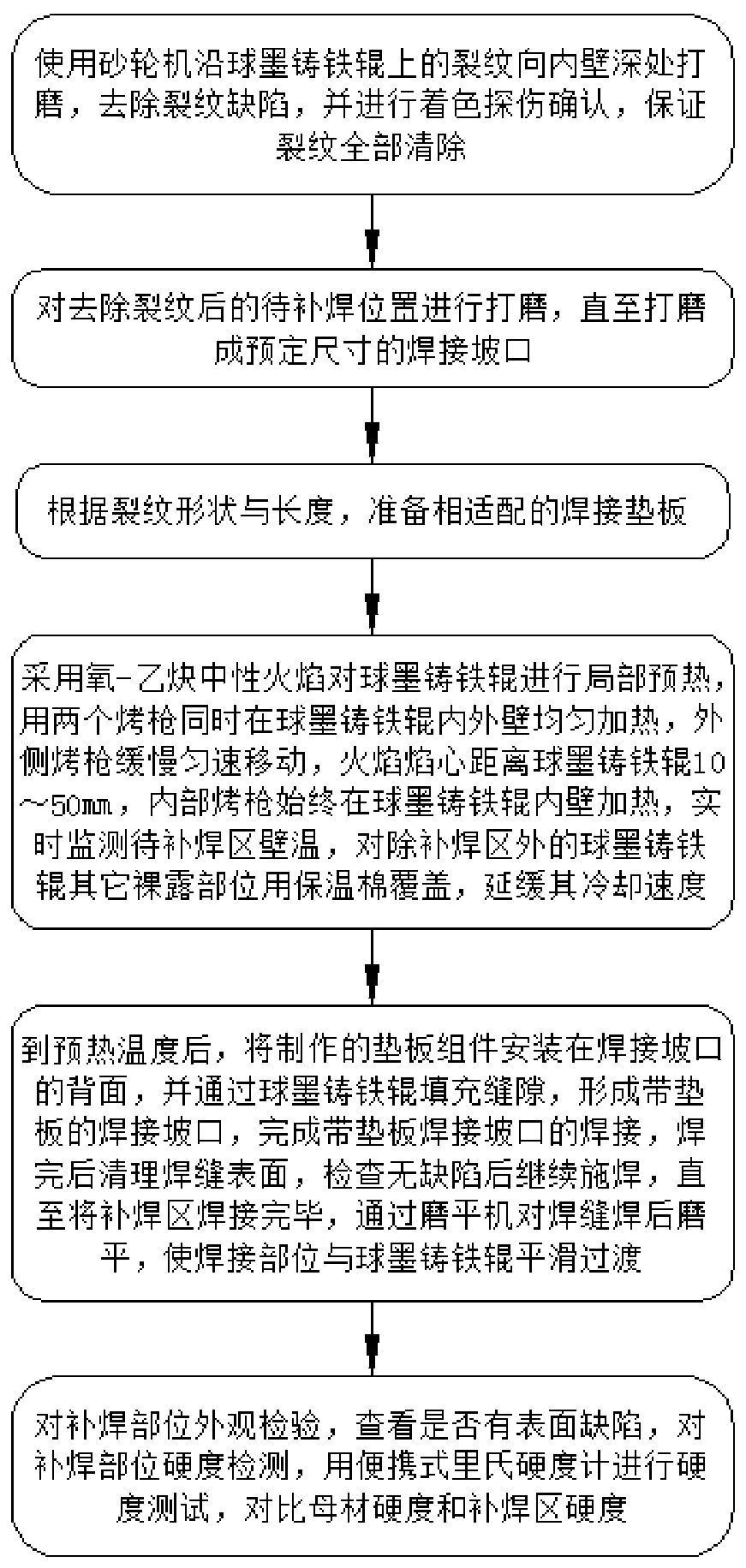

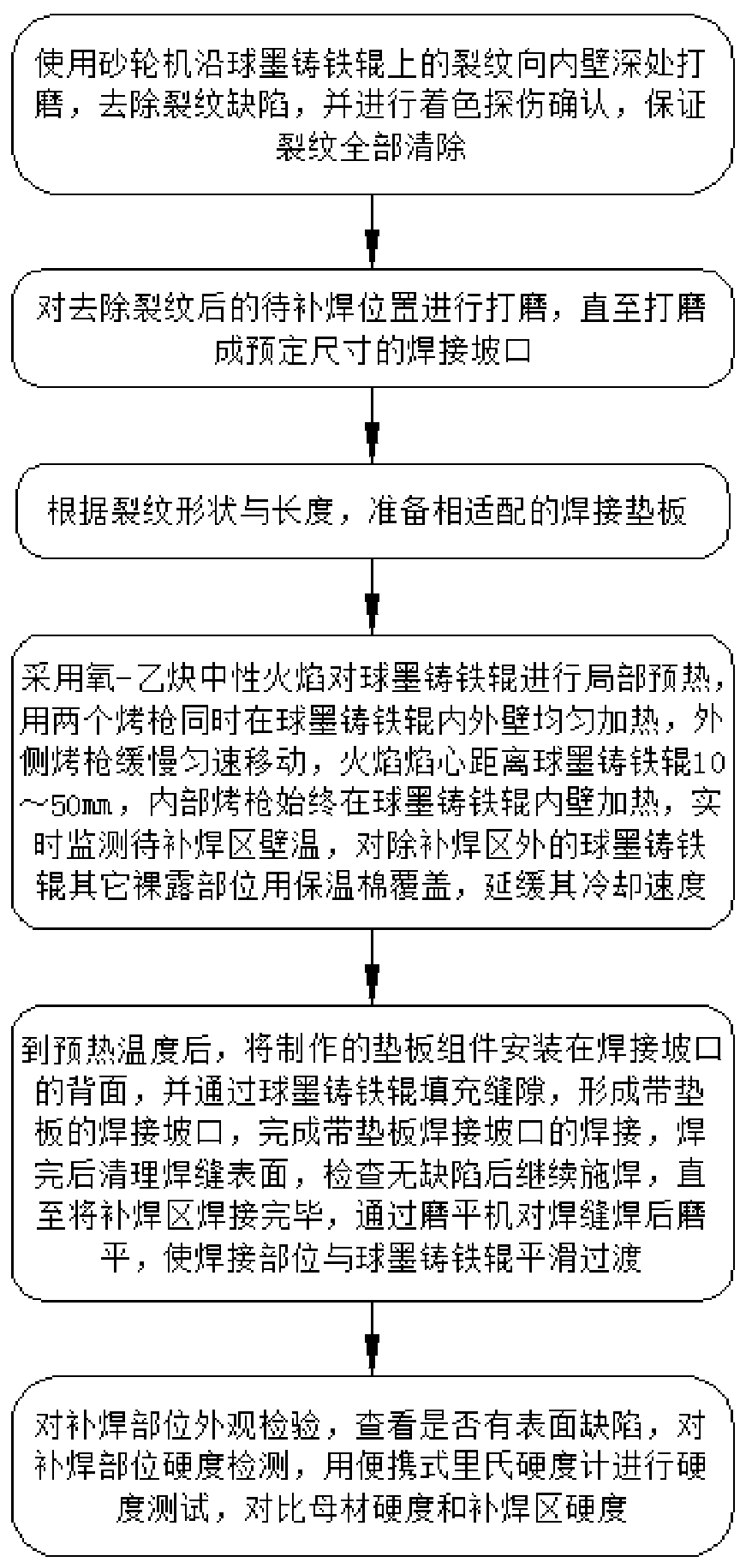

[0027] A repair welding process for a nodular cast iron roller, comprising the following steps:

[0028] S1. Use a grinder to grind along the cracks on the nodular cast iron roller to the depth of the inner wall to remove crack defects, and perform coloring flaw detection to ensure that all cracks are removed;

[0029] S2. Grinding the position to be repaired after the crack is removed until it is polished into a welding groove of a predetermined size;

[0030] S3. According to the shape and length of the crack, prepare a suitable welding backing plate;

[0031] S4. Partially preheat the nodular cast iron roller with an oxy-acetylene neutral flame. The preheating temperature is set to 50°C. Use two baking guns to heat the inner and outer walls of the nodular cast iron roller evenly at the same time. The outer baking gun moves slowly and uniformly, and the flame flame The distance between the center and the nodular cast iron roller is 10mm, and the internal baking gun is alway...

Embodiment 2

[0036] A repair welding process for a nodular cast iron roller, comprising the following steps:

[0037] S1. Use a grinder to grind along the cracks on the nodular cast iron roller to the depth of the inner wall to remove crack defects, and perform coloring flaw detection to ensure that all cracks are removed;

[0038] S2. Grinding the position to be repaired after the crack is removed until it is polished into a welding groove of a predetermined size;

[0039] S3. According to the shape and length of the crack, prepare a suitable welding backing plate;

[0040] S4. Partially preheat the nodular cast iron roller with an oxy-acetylene neutral flame. The preheating temperature is set to 55°C. Use two roasting guns to heat the inner and outer walls of the ductile iron roller evenly at the same time. The outer roasting gun moves slowly and uniformly, and the flame flame The center distance of the ductile iron roller is 30mm, and the internal baking gun is always heated on the inn...

Embodiment 3

[0045] A repair welding process for a nodular cast iron roller, comprising the following steps:

[0046] S1. Use a grinder to grind along the cracks on the nodular cast iron roller to the depth of the inner wall to remove crack defects, and perform coloring flaw detection to ensure that all cracks are removed;

[0047]S2. Grinding the position to be repaired after the crack is removed until it is polished into a welding groove of a predetermined size;

[0048] S3. According to the shape and length of the crack, prepare a suitable welding backing plate;

[0049] S4. Partially preheat the nodular cast iron roller with an oxy-acetylene neutral flame. The preheating temperature is set to 60°C. Use two roasting guns to heat the inner and outer walls of the ductile iron roller evenly at the same time. The outer roasting gun moves slowly and uniformly, and the flame flame The center distance is 50mm from the nodular cast iron roller, and the internal baking gun is always heated on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com