Novel multifunctional automobile gear machining equipment

A technology for automotive gears and processing equipment, which is applied to metal processing equipment, milling machine equipment, details of milling machine equipment, etc. It can solve the problems of reduced production efficiency, lack of lubrication facilities, and complex processing processes of different types of gears to achieve the effect of processing

Inactive Publication Date: 2020-05-19

重庆龙冠机械制造有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The structure and technology of the existing automotive gear processing devices are relatively mature, but the processing process of the existing processing equipment is not easy to operate, the processing process of different types of gears is complicated, the processing equipment is not easy to handle, it is inconvenient to adjust, and the production efficiency is greatly reduced. There is no effective lubrication facility, these problems need to be further improved

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment approach

[0021] As a preferred embodiment of the present invention, a shock-absorbing pad 2 is fixedly installed on the lower side of the base 1 .

[0022] As a preferred embodiment of the present invention, a lubricating pipe 13 is fixed on the upper right side of the installation plate 10 , and a spray head 14 is fixed on the lower end of the lubricating pipe 13 .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

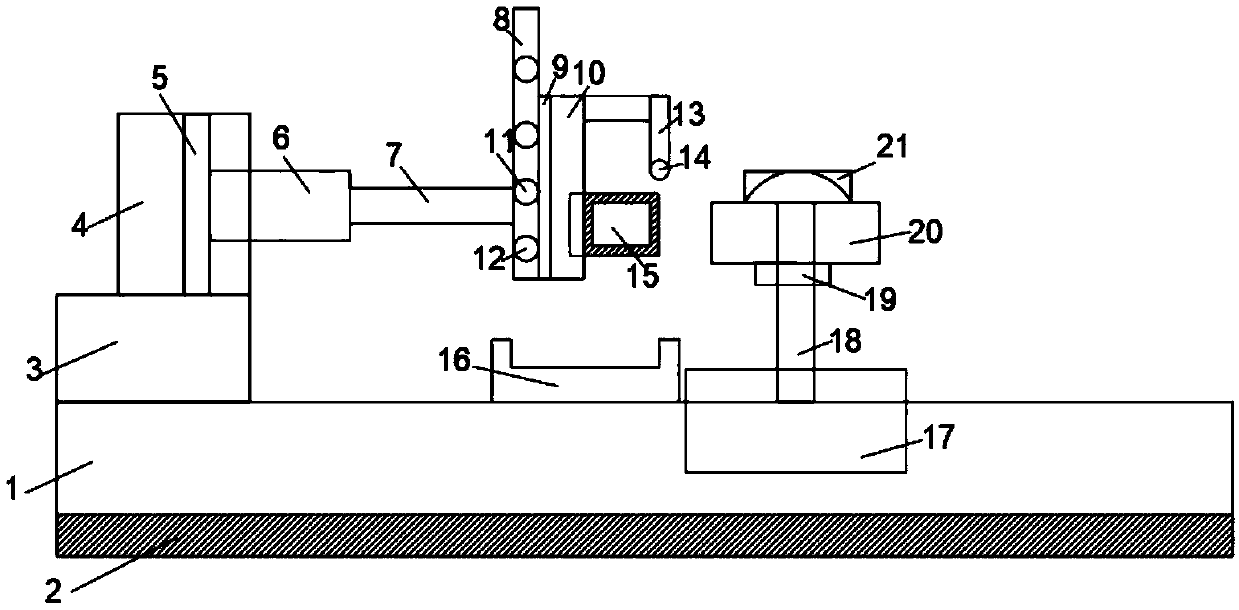

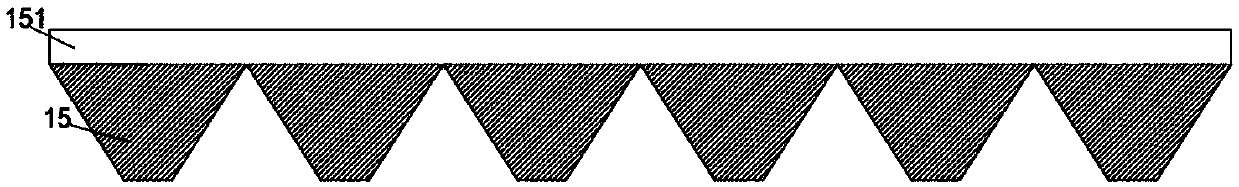

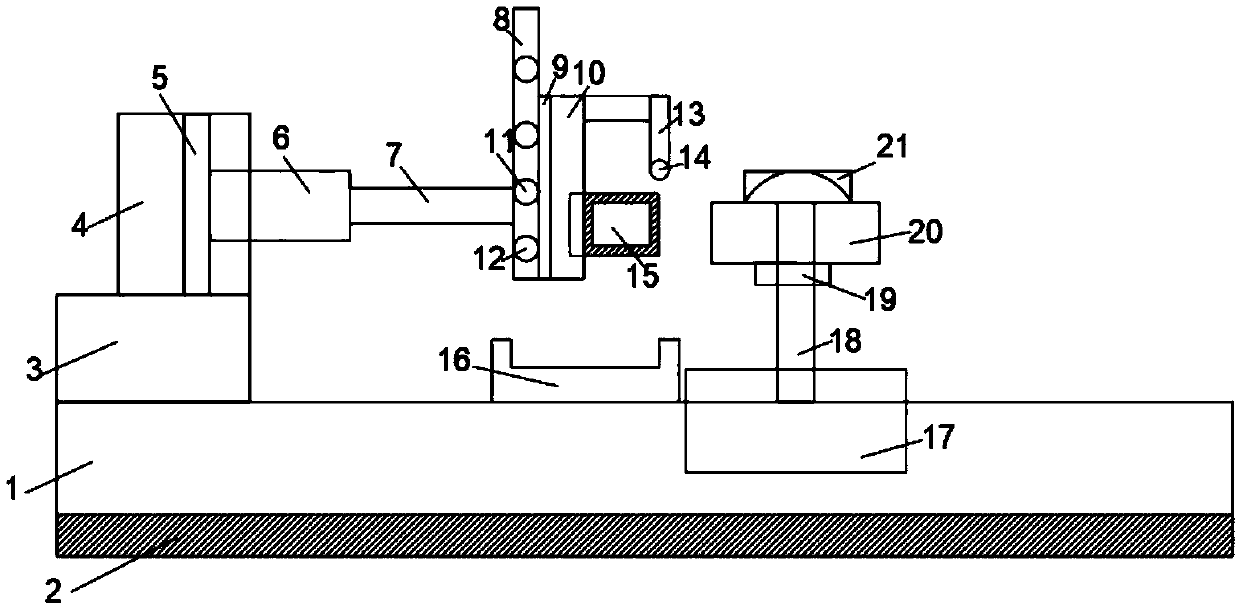

The invention provides novel multifunctional automobile gear machining equipment. The novel multifunctional automobile gear machining equipment comprises a base, a shock pad, an operating floor, an air cylinder, a piston and a piston rod. The operating floor is fixedly installed on the upper left of the base, the air cylinder is fixedly arranged on the upper part of the operating floor, the pistonis fixedly installed in the air cylinder, the right side of the piston is fixedly connected with the left end of the piston rod, the right end of the piston rod is fixedly connected with the left endof a telescopic rod, and the right end of the telescopic rod is fixedly connected with the left side of a sliding rail. According to the novel multifunctional automobile gear machining equipment, products to be machined can be machined through a milling cutter; the height of a milling cutter machine box can be adjusted through the sliding rail and a sliding plate; the milling cutter can be adjusted left and right through the air cylinder and the telescopic rod; waste materials in the machining process can be collected through a water material box; the milling cutter can be lubricated througha lubricating pipe; and the products to be machined can be rotated through a motor and a rotating shaft, and machining is realized.

Description

technical field [0001] The invention relates to the technical field of automobile gear equipment, in particular to a novel multifunctional automobile gear processing equipment. Background technique [0002] A gear is a mechanical element on the rim that can continuously mesh and transmit motion and power. It is a toothed mechanical part that can mesh with each other. The diameter of the large gear is twice the diameter of the small gear. [0003] The structure and technology of the existing automotive gear processing devices are relatively mature, but the processing process of the existing processing equipment is not easy to operate, the processing process of different types of gears is complicated, the processing equipment is not easy to handle, it is inconvenient to adjust, and the production efficiency is greatly reduced. Without effective lubrication facilities, these problems need to be further improved. Contents of the invention [0004] Aiming at the deficiencies i...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B23C3/00B23Q1/26B23Q11/00B23Q11/10

CPCB23C3/00B23Q1/26B23Q11/0067B23Q11/10

Inventor 闫颖涛

Owner 重庆龙冠机械制造有限公司

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com