Flotation method for copper-molybdenum sulfide ore

A copper-molybdenum sulfide and copper-molybdenum ore technology, applied in flotation, solid separation and other directions, can solve the problems of large consumption, easy oxidation of sodium sulfide, and inability to stably control the reduction potential of pulp, and achieve the effect of reducing the amount and achieving excellent results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Copper-molybdenum sulfide mineral raw materials: chalcopyrite and molybdenite, containing 27% copper and 0.54% molybdenum. Its flotation method comprises the steps:

[0041] S1. Pretreatment: Crushing and grinding the raw copper-molybdenum ore until the fineness is -74+45 μm and the content accounts for 85%, and then performing desliming pretreatment to prepare copper-molybdenum ore slurry with a concentration of 35%.

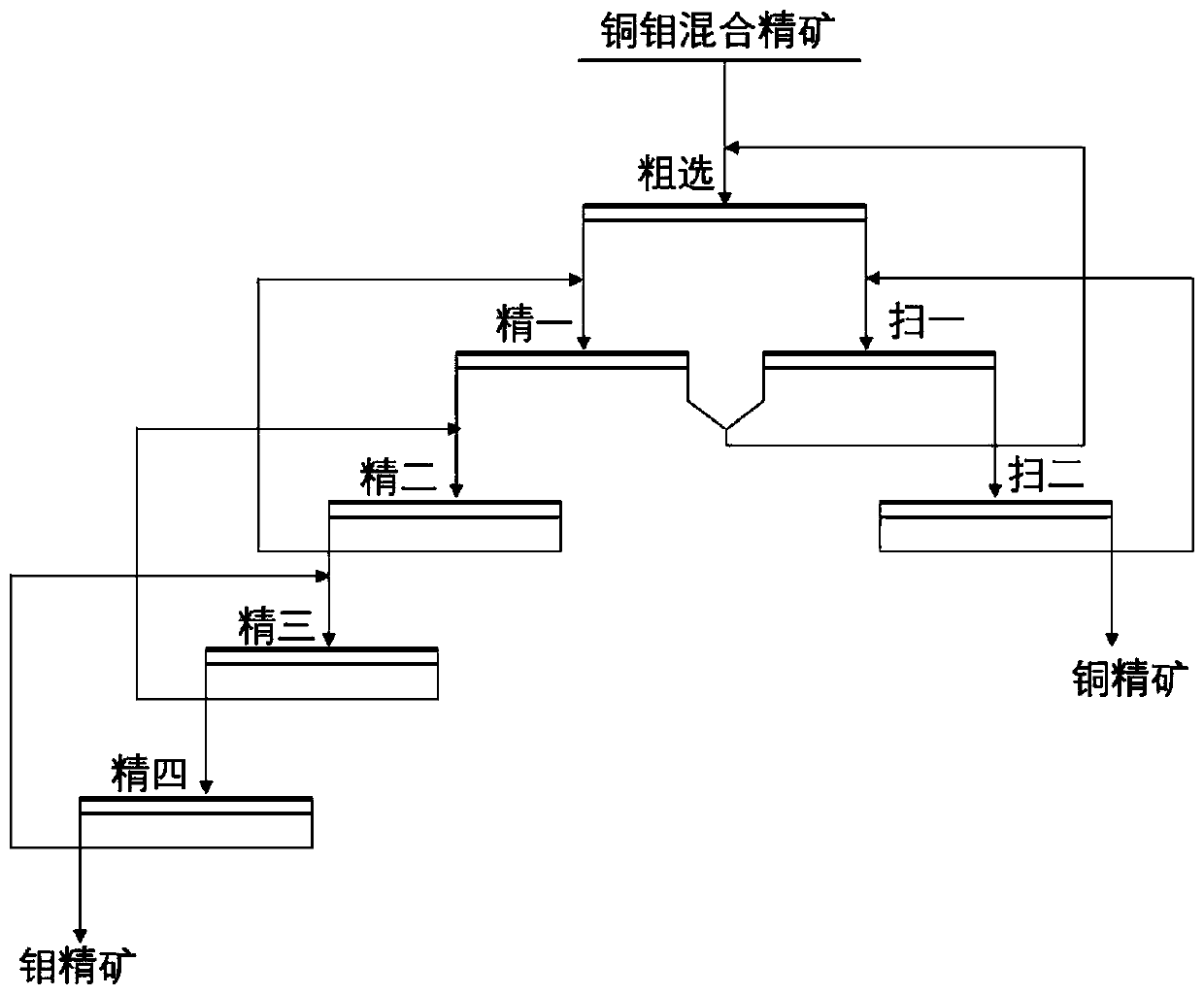

[0042] S2. Mixed flotation: adjust the copper-molybdenum ore pulp with HCl and / or NaOH to adjust the pH value to 9, and add 0.2 kg / t of kerosene collector and 0.1 kg / t of terpineol oil as a foaming agent , carry out a mixed flotation process (such as figure 1 Shown), to obtain copper-molybdenum mixed concentrate.

[0043] S3. Separation of copper and molybdenum: the copper-molybdenum mixed concentrate is made into a mixed pulp with a concentration of 30%, and the pH value is adjusted to 10. The mixed pulp is added to the externally controlled potential...

Embodiment 2-3

[0051] The difference from Example 1 is that the first pH value in the mixed flotation is different, and other steps are the same as in Example 1, and will not be repeated here.

[0052] Table 2 is the setting of the first pH value in the mixing flotation of embodiment 1-3

[0053] Example Mixed Flotation First pH Example 1 9 Example 2 8 Example 3 10

[0054] In the present invention, chalcopyrite and molybdenite have a higher flotation recovery rate in a slightly alkaline environment. In the embodiment of the present invention, collector kerosene and foaming agent terpineol oil have been added to play a strengthening role, which can strengthen the flotation collection effect of chalcopyrite and molybdenite, so that the floating rate of chalcopyrite and molybdenite All reached more than 95%.

Embodiment 4-6

[0056] The difference from Example 1 lies in the difference between the external control potential and the second pH value in the separation and flotation of copper and molybdenum, and other steps are the same as those in Example 1, and will not be repeated here.

[0057] Table 3 is the setting of the external control potential and the second pH value in the separation flotation of copper and molybdenum in embodiment 1 and embodiment 4-6

[0058]

[0059] Under the external control potential, both chalcopyrite and molybdenite have good buoyancy in weak alkaline environment, but molybdenite has better floatability than chalcopyrite. Therefore, the externally controlled reduction potential flotation in a weakly alkaline environment is beneficial to the flotation separation of chalcopyrite and molybdenite, and the pH value of separation flotation is preferably 11.

[0060] Both the buoyancy of chalcopyrite and molybdenite are affected by the externally controlled reduction pot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com