Coal mine underground blasting operation space instantaneous smoke dust rapid elimination device and use method

A technology for working space and dust collection device, which is applied in the field of instantaneous smoke and dust removal devices for underground blasting operation space in coal mines, can solve the problems of secondary hazards of repeated breathing smoke for workers, complicated operation of electromechanical equipment, and downwind air pollution, etc. Overcome the dangerous status quo of rebreathing smoke, eliminate the risk of electricity consumption, and solve the effect of complex operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The technical solutions in the embodiments of the present invention will be clearly and completely described below, obviously, the described embodiments are only some of the embodiments of the present invention, not all of the embodiments. All other embodiments obtained by persons of ordinary skill in the art based on the embodiments of the present invention belong to the protection scope of the present invention.

[0046] The present invention will be described in detail below with reference to the accompanying drawings and examples. It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

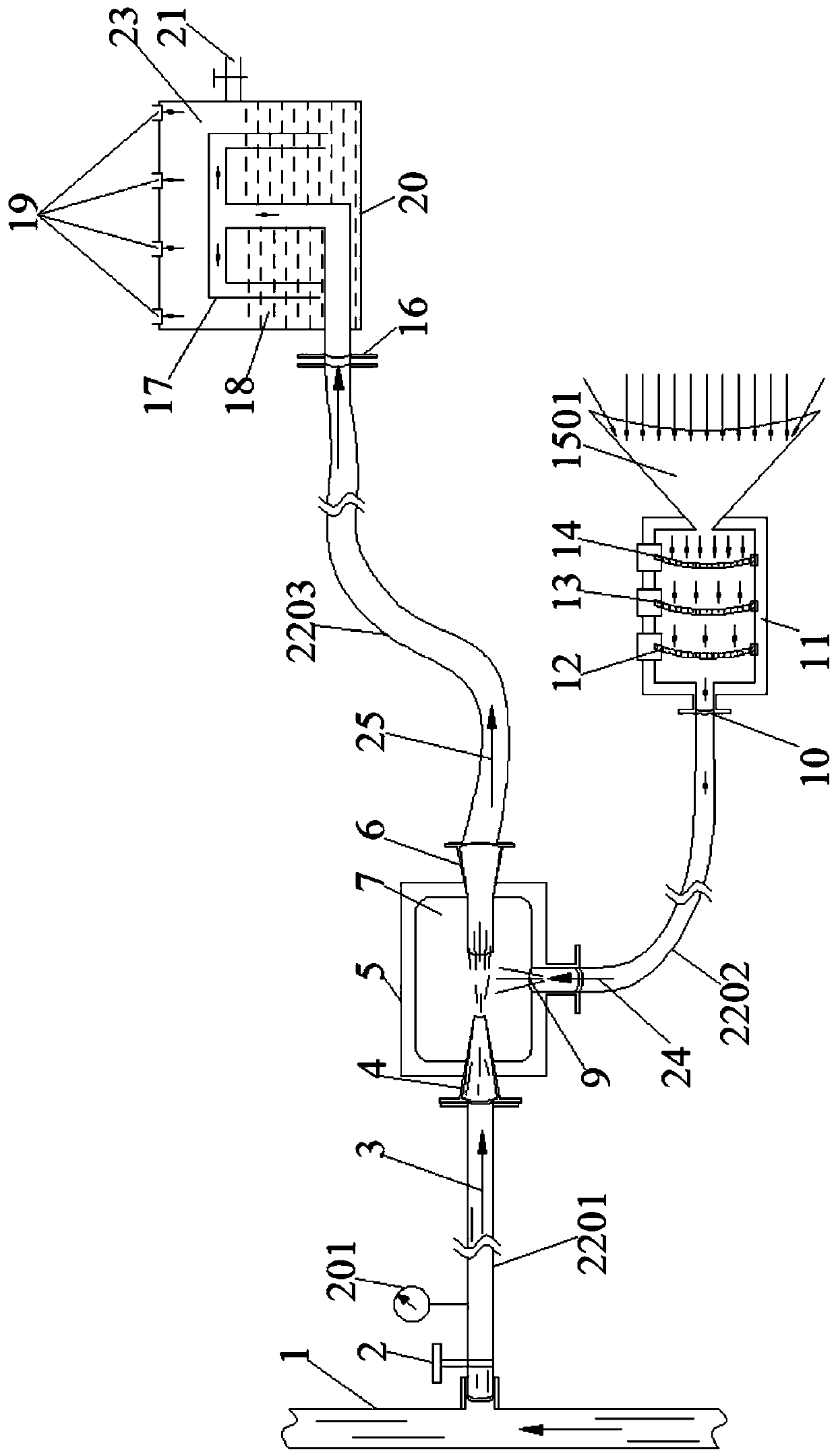

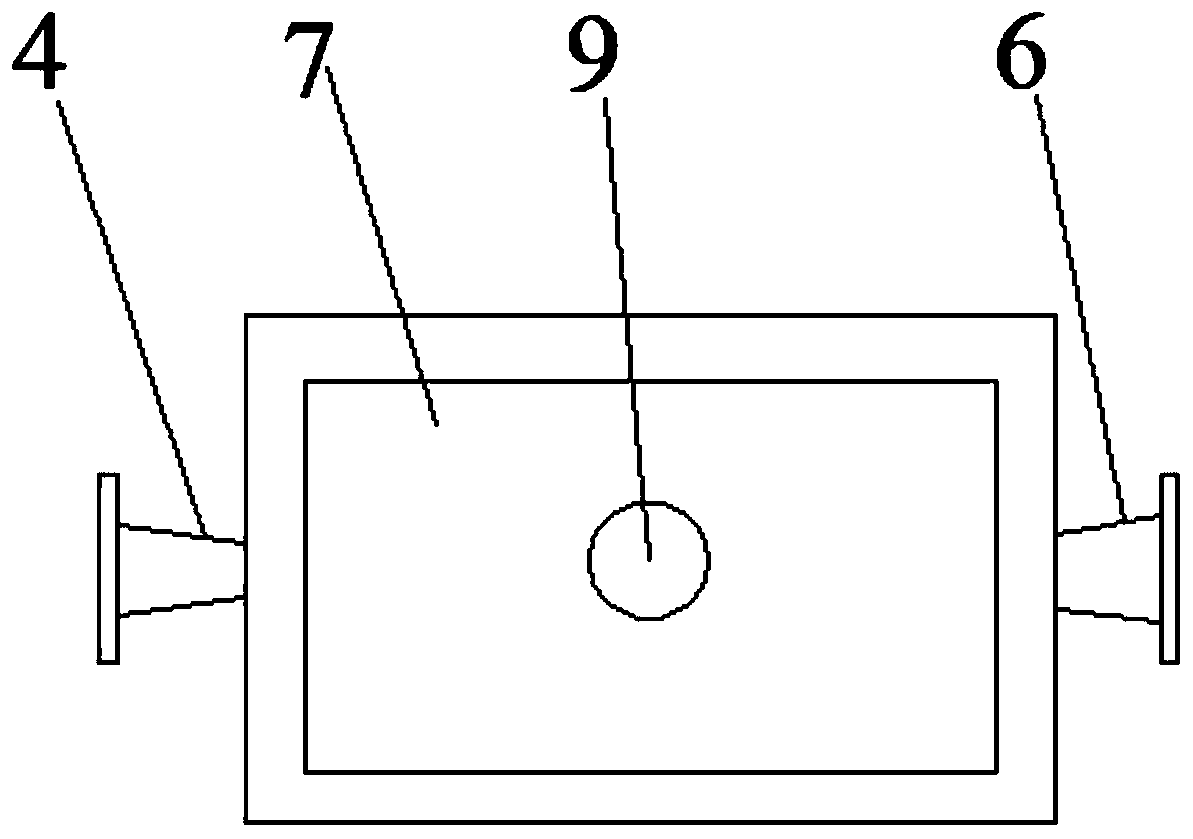

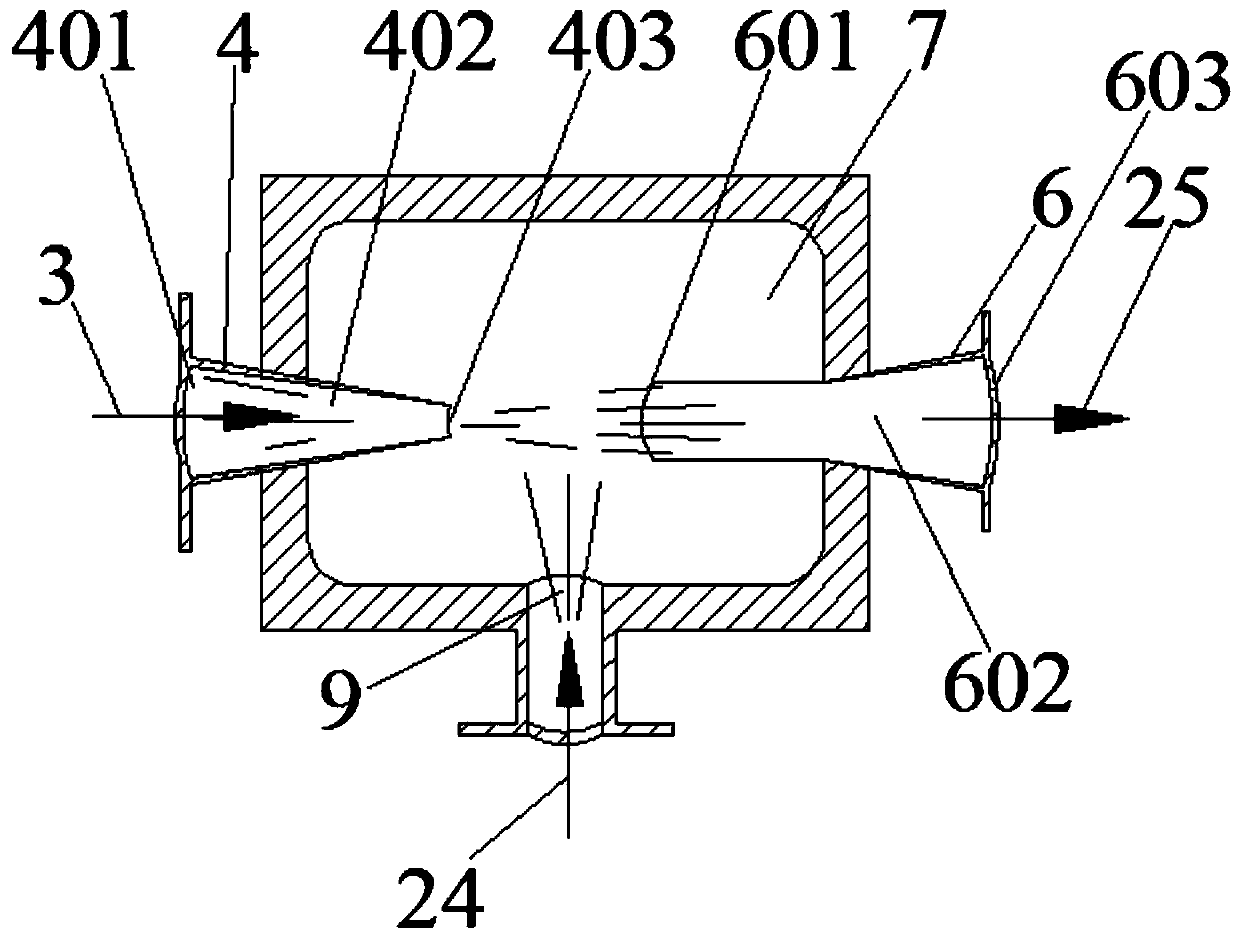

[0047] The invention utilizes the necessary downhole pressure air pipeline system to construct a negative pressure ejection device, a multi-stage negative pressure dust collection device and a high-pressure wet spraying device. The negative pressure ejection device can not only...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com